Longer service life and fewer and shorter machine down times

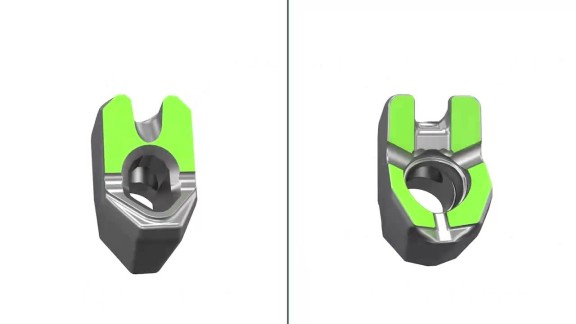

The quick-change toolholder system HT22 PLUS HD is primarily distinguished by its higher wear resistance. The system's exceptionally long service life leads to noticeably longer pick and toolholder replacement intervals during operations on construction sites. It is also characterised by the prismatic design of the contact surface.

At the end of the day, this means that users can look forward to a longer service life of the picks and the quick-change toolholder system. The resulting benefits – fewer pick changes, fewer and shorter machine down times, longer maintenance intervals and higher machine utilisation rates – enable cost-efficient stabilisation of even the most difficult soils and efficient milling and recycling of severely damaged road pavement layers.

The WCC milling tool also has a reliable HT22 interface. This guarantees low-maintenance and operation reliability of the tool in use. The large wear volume in the shoulder section of the WCC milling tool extends the service life of the HT22 toolholder. As a result, the combination of WCC and HT22 enables maximum carbide utilisation of the holder and tool.

Due to their tool geometry and construction materials, WCC milling tools are perfect for mixing cohesive soils interspersed with large rocks or boulders. They have extremely wear-resistant carbide cutting edges that, due to the exceptional strength of the material, exhibit extremely high fracture toughness and consequently offer outstanding impact resistance.

Discover moreChallenging conditions in applications such as cold recycling, granulation or the stabilisation of soils interspersed with large rocks or boulders with maximum efficiency demand ultimate performance from cutting tools. This calls for perfectly matched components designed to meet the highest performance requirements. They can be relied on to provide high milling and mixing performance while simultaneously ensuring maximum resilience and a long service life.

The original WIRTGEN DURAFORCE milling and mixing rotor impresses with extreme wear resistance, impact resistance, and fracture stability for in all soil stabilisation and cold recycling applications: The ideal rotor for every need.

Discover more