BENNINGHOVEN TBA 3000

in Sweden

High-quality asphalt production with KLEEMANN and BENNINGHOVEN plants in Sweden

In a quarry with an asphalt mixing plant attached, Swedish company Asfaltbolaget Sverige AB shows how state-of-the-art technology and a sophisticated process chain combine to increase quality and efficiency: in future, KLEEMANN track-mounted crushing and screening plants will run on electricity in this quarry, producing top-class output materials. The majority of the mineral obtained is then immediately turned into various formulas of top-quality asphalt in an on-site BENNINGHOVEN TBA 3000 asphalt mixing plant which runs on biomass to liquid fuel (BtL). In combination with extremely short transport routes, these innovative energy sources ensure an outstanding level of efficiency.

We find our partnership with the WIRTGEN GROUP very beneficial.

Patrik Magnusson, Production Manager

Asfaltbolaget Sverige AB

After the KLEEMANN plant train has crushed and processed the mineral, wheel loaders transport it a few metres to the asphalt mixing plant. To be more accurate, they transport it to the cold feed units of a BENNINGHOVEN TBA 3000 transportable asphalt mixing plant. The plant automatically draws down the required stone from these cold feed units to suit the asphalt formula in question and conveys it to its dryer drum where it is heated and thus prepared for asphalt production.

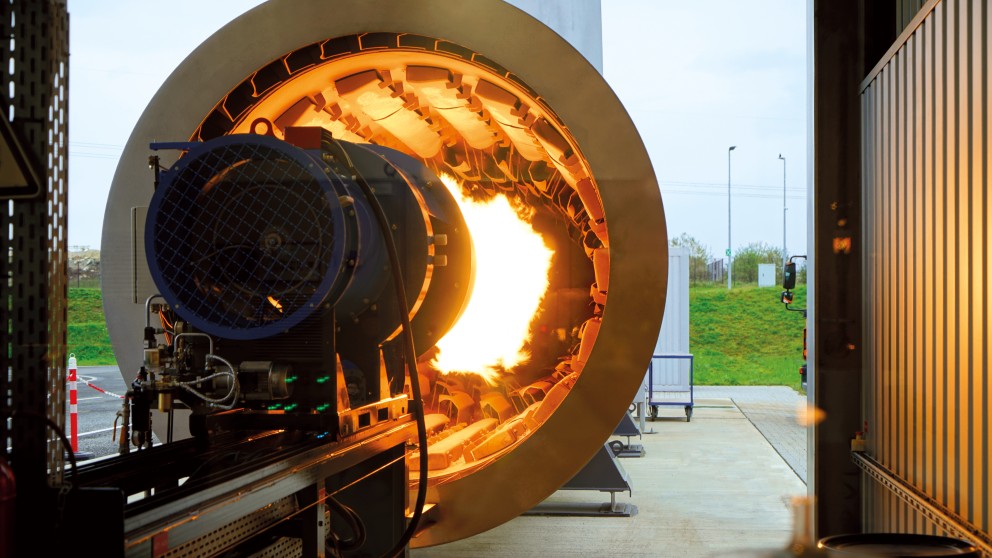

A special feature of the combustion technology of the Furuby plant is BENNINGHOVEN’s EVO JET multi-fuel burner. This prototype is currently being trialled and for the first time, can use biomass to liquid fuel (BtL) as well as heating oil for heat recovery. As BtL is relatively viscous, it is initially heated to processing temperature and transported through heated and insulated pipelines. The option of switching fuels at the touch of a button gives Asfaltbolaget great flexibility. BtL is obtained from wood, making it a renewable energy source which the Swedish state actually supports and subsidizes.

That Asfaltbolaget is prepared to use this form of energy shows that the company is forward-looking and willing to improve. “We want to be out in front. The innovative technologies of the WIRTGEN GROUP make an important contribution by helping us work efficiently with high quality. What is more, BtL has given us an amazing opportunity to be even cleaner,” explained production manager Patrik Magnusson.

The principle of obtaining BtL from wood is as follows: the fuel is a biomass to liquid (BtL) fuel, in other words, involves the liquidization of biomass. The high temperature and high pressure of pyrolysis, a thermochemical conversion process, produces so-called pyrolysis oil from the cellulose-rich wood. The remaining process steps are cleaning, synthesizing and refining the pyrolysis oil into biomass to liquid fuel. In Sweden, the energy to complete this process is provided by emission-free hydroelectric plants.

The challenge for the process technology is the natural source product, wood, as its chemical composition can vary. These variations have an effect on the final product. The consequence of this would be increased operating effort, as the parameters for the burner would keep having to be changed.

To enable the correct basic parameters for the burner to be set at the BENNINGHOVEN factory, the customer sends his heating medium to Germany in a stainless steel container. BENNINGHOVEN tests the fuel and makes the optimum settings on the burner to allow the values to be adopted 1:1 on site in Furuby.

BENNINGHOVEN’s EVO JET burner for biomass to liquid fuelsonce again underlines the company’s role at the vanguard of green technology. The recycling technology for the world’s highest quota of RAP fed into the mixing process (90 + x%) is also a BENNINGHOVEN innovation. Its name: recycling drum with hot-gas generator with counterflow action. This technology is not part of the TBA 3000 in Sweden, because in this market, the quota for RAP feed rates is currently limited to 30%. Multivariable feed is adequate for quotas of this type and is also fitted in the Asfaltbolaget plant. An advantage of the modular concept of BENNINGHOVEN plants is that hot recycling technology to meet higher recycling quotas is quick and easy to implement should it prove necessary in future.

With multi-variable feed, up to 40% of RAP can be added cold to the production process. This means that even small quantities of mixed material from 2 t can be produced, giving mixing plant operators great flexibility. With multi-variable feed, recycled material is fed to the mixer in cycles; this is kinder to the plant because it avoids rapid steam expansions. BENNINGHOVEN’s patented recycling technology allows maximum feed quotas within the cold feed systems.