The PowerFeeder material handling concept

The powerful conveying concept of the MT 3000-3i can transport up to 1,200 t mix an hour, meaning that a 25 t mix truck can be emptied completely in just 60 seconds. The continuous supply of mix increases paving quality and ensures non-stop paving. Construction projects are completed more quickly and more economically.

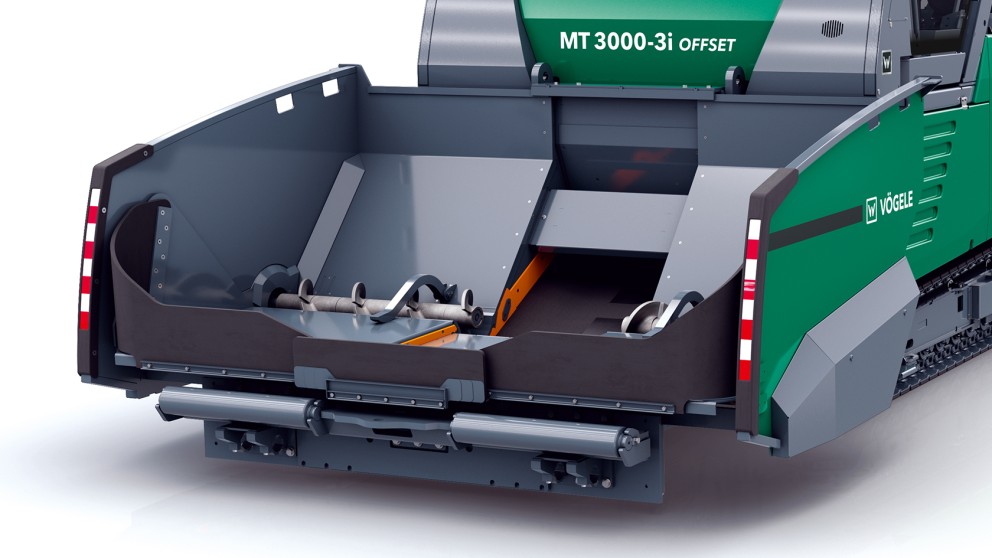

The large receiving hopper with a capacity of 15 t accommodates the mix quickly and without losses. The powerful, hydraulic conveyor and augers with a diameter of 300 mm transport the mix onward. The high-performance conveying concept combined with the large receiving hopper makes it possible to unload a truck carrying 25 t of mix completely in just 60 seconds.

The coloured markings on the material hopper and push-rollers simplify the material transfer process, even in the dark. The offset and the additional seals in the inlet area furthermore prevent loss of material and soiling of the conveyor.

Accurate control and special centring aids ensure that the conveyor remains centred - even when paving a crossfall. The trough-shaped belt furthermore ensures stable transport which is gentle on the mix and prevents mechanical demixing. This prevents loss of material and reduces wear on the components.

Optimum control of belt heating reliably maintains the mix at temperature and counteracts adhesion of the material. Belt temperature is measured and controlled by a sensor. Even critical mixes such as low-temperature asphalt can thus be conveyed without temperature losses.

The versatile applications of the MT 3000--3(i) Offset: in addition to the primary belt, the offset feeder has a long pivoting conveyor. This can be rotated 55° to the left and right - to feed from the side or for hot to hot paving. The lateral distance from the feeder to the centre of the discharge point is thus no more than 3.5 m. The pivoting conveyor can be raised 23° above horizontal to a transfer height of 3.5 m - this can even be increased to 3.9 m as an option. It is perfect for supplying InLine Pave trains or pavers which have a really large extra material hopper, for example.