Focus on the environment with HAMM innovations

Many of the most recent development projects at HAMM have focused on protecting the environment, and reducing fuel consumption and CO2 emissions. This includes looking at the machines, in particular the Power Hybrid concept for energy-saving compaction. Furthermore, every HAMM roller can now be operated with bio-fuel and filled with rapidly biodegradable hydraulic oil. During the construction process, the process optimization guarantees reduced emissions thanks to the "Smart Doc" app. Last but not least, HAMM is reducing the its CO2 footprint "ex-works" – HAMM AG's main plant has been certified in accordance with ISO 14001 since November 2020.

Power Hybrid: Intelligent use of energy

In the HD+ 90i PH tandem roller with power hybrid drive, HAMM combines a classic combustion engine with a hydraulic accumulator. The diesel engine provides the base load while the hydraulic accumulator covers the peak loads. As soon as the power demand falls below the maximum load of the combustion engine, a pump fills the hydraulic accumulator. If a lot of power is called for, the hydraulic system functions as an auxiliary drive, able to supply a maximum short-term load of up to 20 kW. Thanks to this technology, HAMM can ensure that the roller delivers the same power while equipped with a smaller diesel engine. Furthermore, an electric fan drive and an efficient start-stop system relieve the engine. This means that a 55.4 kW engine output suffices for the HD+ 90i PH, instead of the 85 kW power unit in the standard version. After 500 hours of use, findings from analyses of the Power Hybrid roller by the Swedish construction company NCC showed two important things: The PH roller invariably delivered the same compaction power as its sibling model without hybrid technology. At the same time, NCC reported fuel consumption savings of approx. 15%, which also means that the CO2 emissions have been significantly reduced.

Use of the HD+ 90i PH in Sweden

Sweden is a pioneer when it comes to environmental protection. In general, in Scandinavia, environmental friendliness is an important criterion when selecting the machines. It was no surprise when the Swedish construction company NCC was one of the first companies to use the HD+ 90i PH tandem roller. When compacting a wide range of asphalts, the fuel requirement is reduced by 15% with identical compaction power.

Applications in Southwest France

The spectrum ranged from urban projects to the renovation of rural roads, for which a wide range of asphalts had to be compacted. Two experienced drivers tested the new machine and both agreed that the low interior noise level made it an extremely pleasant working experience. Otherwise, they could detect no difference to the 85 kW roller in respect of driving and compaction.

Vegetable fuels for all HAMM rollers

On the way to a climate-neutral construction industry, HVO will likely play a key role for a long time. HVO means "Hydrotreated Vegetable Oils", since this fuel is produced from vegetable and animal fats. In a chemical process, the properties of the fats are adapted to those of diesel fuel. Plant oils that are prepared in this way can be mixed in with the diesel fuel or can replace it entirely. Operation with HVO has many advantages: These fuels are cold-resistant down to -22 °C or lower, they age significantly more slowly than fossil diesel fuel, and produce less nitrogen oxide and fine dust during combustion. HAMM recognized the opportunities offered by this fuel at an early stage. This means that, today, all of the latest models can be operated with pure HVO or a mixture of diesel and HVO. Furthermore, the hydraulic components in all of the latest HAMM rollers can be operated with hydraulic oils, which are particularly quick to biodegrade.

HVO in all HAMM rollers

Synthetically manufactured HVO, i.e. fuels that are extracted from vegetable and animal oil and fat wastes from the food industry, allow for extremely environmentally friendly operation of the HAMM rollers. In all HAMM rollers, HVO can be mixed in with the diesel fuel or can replace this entirely.

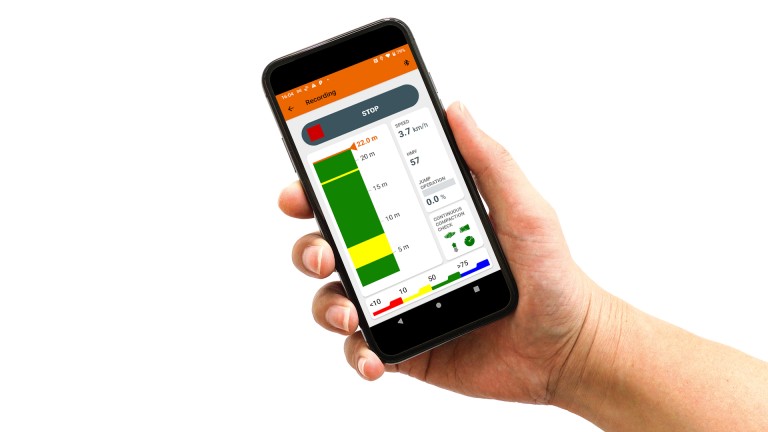

Smart Doc: Process optimization and compaction documentation

With Smart Doc, the Android app from HAMM, users can transparently document the compaction in the earthworks and share the result with third parties. When developing the app, the focus was on the possibility of self-monitoring when it comes to compaction in earthworks. Smart Doc also fulfills the minimum requirements of continuous compaction control (CCC). The app is also helpful when training new drivers, since all relevant compaction parameters are visualized on the smartphone in real time. Smart Doc records data as soon as vibration or oscillation is used during compaction. The compaction data is visualized in real time. Furthermore, a compaction report can be generated at any time. In this way, Smart Doc helps the construction companies to achieve verifiably high-quality compaction for earthworks with the required basic continuous compaction control. At the same time, the number of passes is optimized. This also reduces the diesel consumption and, as a result, the CO2 emissions. The app is free and can be installed via the Google Play Store on all Android smartphones and tablets from Android 6.0. It is available in German and English, Spanish and French.

Smart Doc

Smart Doc, the app from HAMM, shows in real time how the compaction of the respective pass develops. During compaction, Smart Doc records the speed, the frequency, the amplitude, the proportion of jump operation and the achieved compaction value (HAMM Measurement Value). With Smart Doc, a test report can be automatically created and sent as a PDF – an easy but nevertheless reliable and accurate basic proof of continuous compaction control. For inexperienced drivers, the app is also a great help when it comes to training.

Smart DocEnvironmental protection ex-works in accordance with ISO 14001

In just two years, HAMM has established an extensive environmental management system and, in November 2020, was certified in accordance with ISO 14001. In doing so, goals were set for how to reduce emissions, protect resources, and minimize risks in the future. With the aid of various measures, the company will be able to continue to improve its environmental performance in the future. However, HAMM has been working on saving energy for considerably longer. As a result, the administration building has been heated and cooled via a geothermal energy system, that is to say, using renewable energy from the soil, since 2013. This prevents 86 t CO2 every year. CO2 emissions are also drastically reduced in many areas in production. Among other things, losses in the compressed air system were systematically identified and eliminated. Another project was the development of a special low-solvent, one-layer paint for the drums in cooperation with the paint suppliers. In conjunction with ISO 14001, HAMM will optimize heating in the production halls in the near future and, as a result, reduce gas consumption. Furthermore, HAMM has set itself the goal of reducing the amount of waste per machine by 20% by 2023. Various measures are required for this and these are being gradually implemented by the teams from Logistics, Purchasing, and Production Planning.

Continuous improvement

HAMM has been working on building an environmental management system since 2018. In 2020, Tirschenreuth-based company was certified in accordance with ISO 14001. This will help the company continue to improve its environmental performance in the future, reduce emissions even further and save resources.

ISO 14001

Efficient and digitalized

Optimally organized assembly halls, production facilities and logistics divisions form the basis for a highly efficient roller factory. The digitalization of the logistics and manufacturing processes plays a key role here and significantly reduces the paper consumption, for example, thus making many processes more efficient.

Tandem roller with two vibration drums

| Weight | 9,700 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |

Tandem roller with two vibration drums

| Weight | 9,220 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |

Tandem roller with vibration drum and set of wheels

| Weight | 8,960 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |

Tandem roller with vibration drum and set of wheels

| Weight | 8,720 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |

Tandem roller with vibration and oscillation drum

| Weight | 9,460 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |

Tandem roller with vibration and oscillation drum

| Weight | 9,220 kg |

| Drum width | 1,680 mm |

| Exhaust emissions category | EU Stage V / EPA Tier 4 |