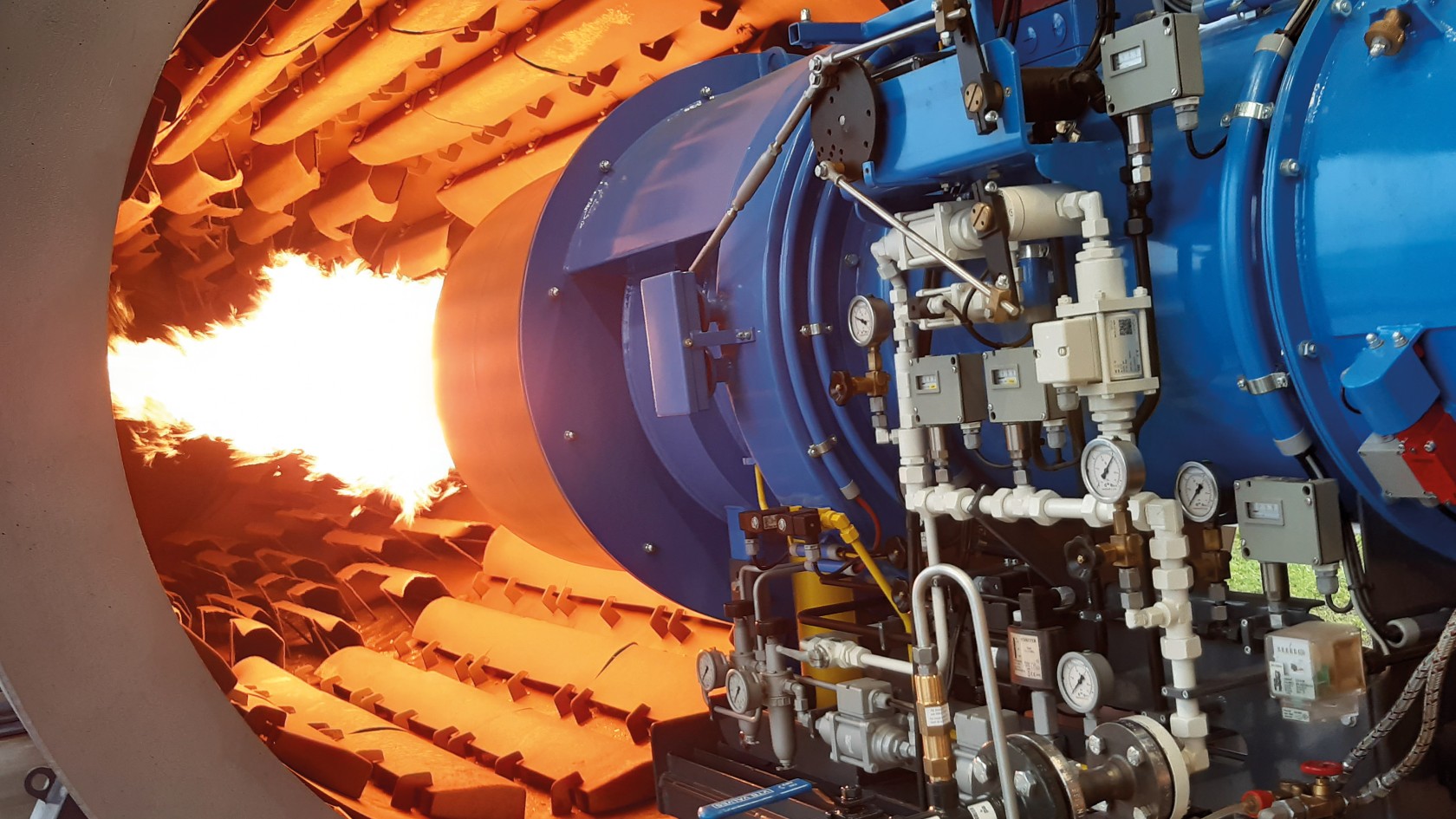

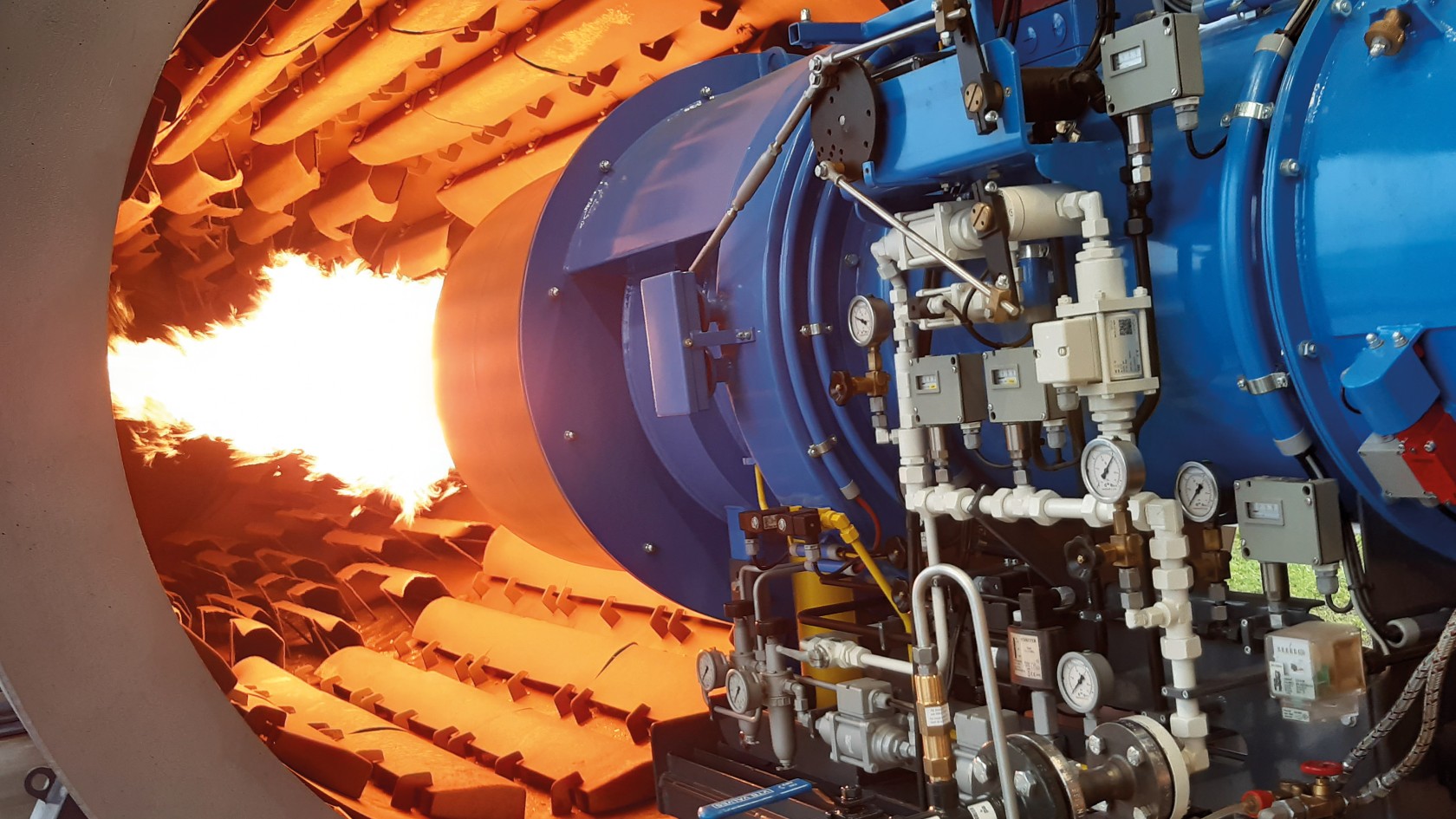

Benninghoven burners EVO JET

BENNINGHOVEN is a world market leader in burners for asphalt mixing plants and a manufacturer of multi-fuel burners with up to 4 fuels. The complete know-how and wealth of experience from over 70 years of burner competence support the development of unique burners with excellent properties.

Relentlessly rising energy costs and the need for careful management of limited resources require innovative technologies plus continuous improvement. The EVO JET burner has been developed by BENNINGHOVEN’s research team to meet real-world needs.

BENNINGHOVEN’s established and well-known approach to usability also played a key role in the development of this burner. The burner features a modular, highly accessible design.

The burner is mounted on a chassis to ensure it can be easily moved into place for maintenance work. A frequency converter system ensures that both the burner fan and oil pump are perfectly coordinated with one another, and can work throughout all control ranges. As a result, only the specific level of consumption requested is used for drying, whatever the output setting. Redesigned from scratch, the new silencer keeps noise to a minimum while simultaneously improving the energy conversion efficiency of combustion. This is achieved by the new air inlet layout. The improved energy conversion efficiency results from trapping the heat radiated by the front wall of the drum and re-routing the preheated air to the burner. This, in turn, means less energy is required to preheat the air, which helps to lower the costs of fuel. Burners in the EVO-JET series feature mature designs for all fuel types and have been comprehensively field-tested. This energy-saving program is rounded off by BENNINGHOVEN installing only electric motors compliant with the new IE 2 (or IE 3) standard – soon to become mandatory.

100% green hydrogen system for road construction

With the first burner anywhere in the world that can be run up to 100% on green hydrogen, BENNINGHOVEN offers a forward-looking solution for greater sustainability in roadbuilding.

All from a single source – From the hydrogen source itself, the scope of delivery from Benninghoven covers the feed systems plus pressure regulation section, multi-fuel burner, hydrogen control section, burner control and plant components adapted to run on hydrogen.

The burner also ships with a new control system, while the carefully coordinated hardware and software solution keeps the asphalt production process cost-effective.

Burner technologies from Benninghoven can be used to equip both new plants as well as existing asphalt mixing plants. Retrofit solutions can also be deployed in plants from other manufacturers. This gives any plant operator the chance to start using the latest technologies whenever they want to – a key aspect for ensuring cost-effective, sustainable asphalt production and long-term job security.

Download