Smart Compact in earthworks

Assistance system for increased process reliability: With the Smart Compact compaction assistant in its compactors, HAMM automatically adjusts the compaction energy to suit the ground conditions. This is why HAMM developed the VA drums (VA = variable amplitude). This increases the process reliability and the quality of the compaction reaches a new level. At the same time, it actively takes the pressure off drivers.

Variable compaction energy

In earthworks operations, Smart Compact on the compactors with VA drums helps to direct the energy into the ground extremely efficiently. The driver simply has to select the target value (in MN/m²) for the load-bearing capacity of the ground. During compaction, the current load-bearing capacity value SCV (Smart Compaction Value) of the ground (in MN/m²) is calculated by Smart Compact. The compaction assistant then automatically positions the unbalance system in the corresponding VA drum so that it always vibrates at the optimum amplitude.

In this way, Smart Compact automatically adjusts the compaction force to the load-bearing capacity achieved thus far. This way, the compaction target is reached quickly and reliably, without the roller going into jump operation. This preserves the machine components and extends the service life of the rollers. At the same time, it also prevents over-compaction and reduces the number of passes.

Smart Compact is available for compactors in the HC series with VA drum.

The required ground firmness and the frequency are selected via the display on the operator’s platform. This also displays the current load-bearing capacity (SCV) in MN/m², as well as the current compaction adjustment for the drum.

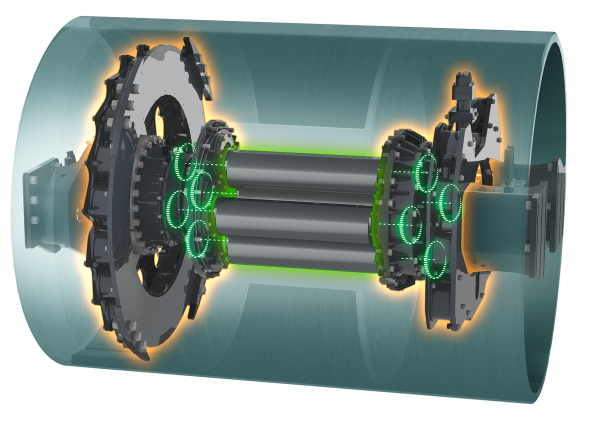

Flexible rotary vibrator

The VA drum works on the principle of the rotary vibrator. It has an unbalance system with fixed and adjustable weights. Depending on the position of the weights relative to one another, the amplitude of the vibration changes.

Fuel savings included

With Smart Compact, the amplitude of the VA drum can be set automatically to any increment or manually adjusted to one of five levels. Whenever the maximum compaction force is needed, the drum vibrates at the highest amplitude. In all other situations, the fuel consumption reduces.

Targeted adjustment of static depth effect

When compacting with Smart Compact, the energy is directed into the ground even more efficiently. This results in higher process reliability, since Smart Compact delivers impressive compaction results. As a general rule, large amplitudes produce a large depth effect, whilst small amplitudes produce a low depth effect.

Suitable for thicker layers of bulk material

Thanks to its intelligent design, the maximum amplitude of the VA drum is larger than the normal vibration drums, enabling it to produce far greater centrifugal forces, up to 30% higher than those produced with a standard drum. Consequently, the VA drum can homogeneously compact layers of bulk material of a greater layer thickness.

Compactors

Tandem rollers

Pneumatic-tire rollers