Surface Mining Technology

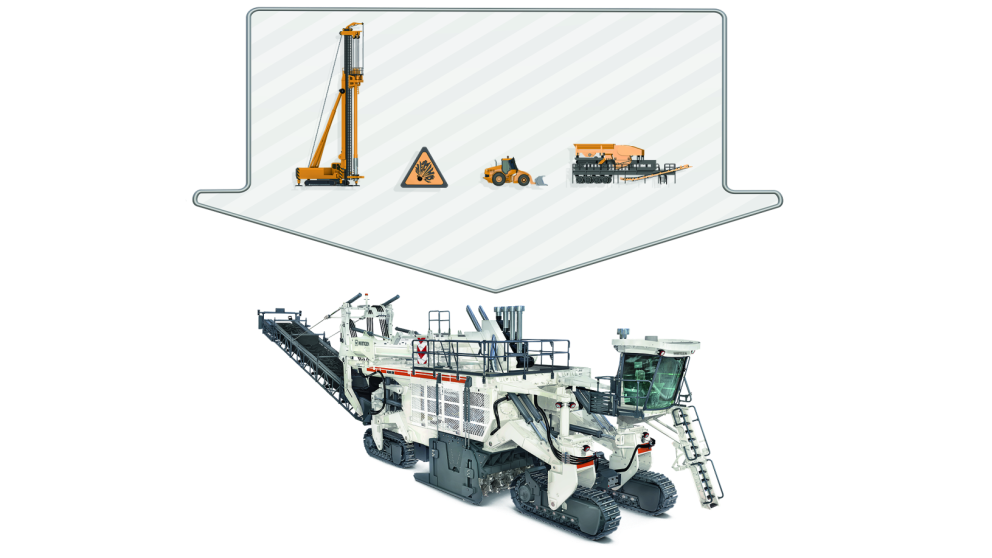

WIRTGEN’s expertise in advanced cutting technology makes it possible to selectively mine mineral deposits without drilling or blasting – in the most environmentally friendly manner and with the purest quality!

Discover the operating principle and technical components of surface miner technology. Become familiar with our state-of-the-art cutting technology and learn more about new ways of mining minerals.

While the surface miner moves forward, a special cutting drum rotates against the direction of travel, cuts material layer by layer from the rock formations, and crushes it in the process. The primary conveyor receives the rock from the drum housing and transports it to the end of the machine, where it is transferred to the height-adjustable discharge conveyor that features wide swing angles. From there, the material is loaded onto trucks or dumpers or sidecast. The discharge height can be adjusted to match the size of the available transport equipment. The surface miner is driven by four steerable and height-adjustable crawler units. An automatic leveling system ensures that the machine maintains the exact cutting depth. This allows even thin seams or layers to be selectively mined with maximum precision.

Surface miners are just one link in a process chain, but they have a major impact on the entire process – especially the end result. This innovative process stands out due to the following key features:

Cut, Crush, and Load in a Single Operation

The mined material is cut, crushed, and, if required, directly loaded in a single operation. Conventional primary crushing of the rock as an additional operation is no longer necessary. This makes surface miners significantly more cost-effective than conventional drilling and blasting processes with subsequent material loading.

Selective Mining

Surface miners selectively mine raw materials, achieving a high degree of purity and maximizing exploitation of the deposits. The selective process significantly reduces the amount of equipment, personnel, time, and overburden – and the capital expenditure is also considerably lower.

Eliminate Blasting and Create Stable Surfaces

Stringent environmental regulations governing noise and dust emissions make vibration-free surface mining an attractive alternative to drilling and blasting. The stable, precise, even surfaces created during mining, earthworks, and rock construction can be directly used as road surfaces, tunnel floors, or embankments.

Minimal Environmental Impact

We not only develop innovative machines of exceptional quality. Our permanent goal is also to keep the environmental impact of our machine technology as low as possible. WIRTGEN surface miners are a prime example of this – they feature environmentally friendly technology that cuts, crushes, and loads rock in a single operation. The tremendous advantage of the selective mining method is that vibration-free material extraction without drilling and blasting produces very little dust and noise. At the same time, the low environmental impact makes it possible to fully exploit the deposits, even in the immediate vicinity of residential areas. When using the selecting mining method, the area required to extract high-quality material is much smaller than with conventional methods. Our fuel-efficient, intelligently controlled engines meet the strictest emissions standards.

WIRTGEN is the world’s leading manufacturer of machines for extracting minerals by cutting in open-cast mining. WIRTGEN surface miners extract raw materials such as coal, gypsum, iron ore, salt, phosphate, bauxite, limestone, or granite in high purity. They are also increasingly being used as the primary extraction equipment in newly developed open-cast mining areas and in open-cast mine extensions.