Power Hybrid by HAMM – environmentally friendly compaction

As environmental protection becomes a more important issue, reducing fuel consumption and CO2 emissions has also become increasingly relevant. These objectives have long been present in the construction machinery industry. When it comes to compaction technology, HAMM offers an intelligent overall concept – the power hybrid drive, which provides full (compaction) power while protecting the environment.

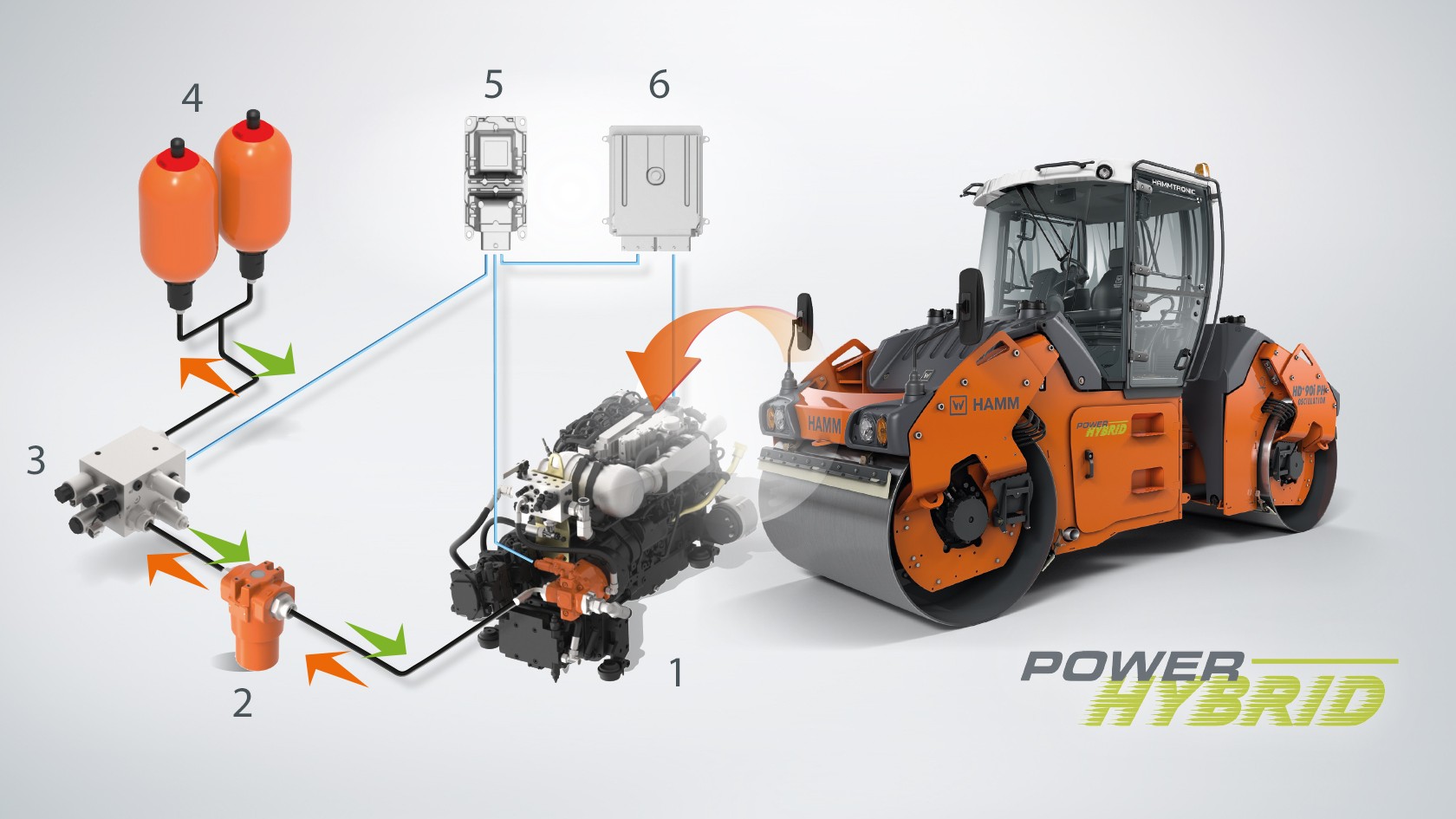

The Power Hybrid concept at a glance:

HAMM currently offers the hybrid drive for the 9 tonne HD+ 90i PH tandem roller (EPA Tier 4/EU Stage V) in a range of variants (VV, VV-S, VO, VO-S, VT, VT-S). For these models, HAMM combines a classic combustion engine with a hydraulic accumulator. While the diesel unit provides the basic load, the hydraulic accumulator is able to cover peak loads, such as start-up or activating vibration/oscillation, by providing an additional 20 kW of power at short notice. After this maximal load has been generated, the hydraulic accumulator is recharged via a pump. Since the maximum load is generally only required for a few seconds, sufficient recharge time is available. Additionally, the diesel engine's workload is reduced by an electric fan drive with optimum efficiency and an efficient start-stop system. This means that an engine that provides 55.4 kW of power is sufficient in the HD+ 90i PH instead of the 85 kW unit in the standard HD+ 90i model.