The 3 x 3 of logistics at Hamm

Efficient, sustainable and resource-saving

Hamm AG’s portfolio incorporates 50 series with 250 different models. In order to fulfil requirements that can at times greatly vary between markets and customers, Hamm offers a total of around 1,400 options. The variety presented by the variants is similarly broad. And this is precisely why virtually all machines are produced in a “batch size of 1”.

A single roller can comprise up to 10,000 parts. That’s why the reliable and punctual supply of assembly lines with the necessary parts and operating materials is as vital as the blood running through our veins: Without it, everything comes to a stop. And this is why Hamm is always pulling out all the stops to optimise the logistics and adapt it to meet requirements. All the while, Hamm is also maintaining a focus on sustainability and responsible use of resources.

For Hamm, flexible logistics is key to a successful production run in which every machine is assembled precisely to customer specifications. The components for the rollers are stored either in the 10,000 m² logistics centre or at the large external warehouse.

It takes the work of some 100 people to ensure the planning, storage and internal transport of all the parts from inward goods to the assembly lines. They plan the processes in the plant down to the very last detail and are always working to optimise the logistics conditions. To this end, they work very closely with Production Planning, as well as the teams in Series Servicing and Development, Quality Assurance and Procurement.

View of the assembly lines.

Other employees inspect the quality of the incoming goods and make sure that the parts and operating materials are securely stored and protected from damage and ensure that these can be transported from the small parts warehouse (ASPW) or one of the pallet bays to the right location in the plant whenever they are needed. This entire logistics process is run digitally – from inward goods all the way to the assembly line.

For the best possible control over the processes, Hamm‘s strategy for logistics is to be responsible for its own transport as far as is possible – whether from the nearby town or from another country. Consequently, coordinating the multitude of suppliers and the number of parts is an extremely complex task.

When it comes to the supply of purchased parts and semi-finished products, Hamm makes beneficial use of the 4PL method. This keeps empty trips to a minimum.

An integral element of transportation is the transport packaging. This is why Hamm has worked with its logistics service providers to develop specialist transport racks that can accommodate more parts in a tight space. As a result, less packaging is required and fewer trips are needed. At the same time, these racks ensure that the parts arrive at the plant undamaged.

To minimise how far the goods have to travel in the plant, Hamm made optimisations when constructing the halls and areas to create a “plant of short distances“. This concept begins right from the point of supply: Various deliveries are gathered together in the buffer store and brought to the logistics centre with a special trailer, rather than every delivery being transported one by one with a forklift truck.

Temporary storage in the outdoor area.

Since 2017, Hamm has been storing its small parts for supplying production in the ASPW, the fully automated small parts warehouse. They are stored in up to 31,000 containers, split across 6,000 bays. This allows small parts, especially those that are used frequently, to be stored in a very space-saving way that is still “dynamic“. This means items do not have fixed storage locations; instead, they are moved around during storage. Consequently, order picking is a fully automated process: The warehouse system automatically places the requested parts into a transport container.

Parts that cannot be stored in the ASPW due to their weight or shape, are preferably supplied in pallet cages or on pallets and stored in a special area. For picking the goods from both warehouses, the employees use smartphone-style mobile devices and complete everything in a tugger train. Four tugger trains follow optimised routes in order to keep the logistics centre supplied and stocked at the intended workstation at the corresponding assembly line.

This system facilitates highly efficient coordination between Production and Logistics – paper-free of course. All this increases quality, since it virtually eliminates incorrect deliveries, the wrong goods or wrong volumes within Production.

Since 2023, Hamm has also been producing fully electric battery-powered rollers. Consequently, the logistics team has been taking care of storing and internally transporting Li-ion batteries. New measures included developing an entirely separate flow of goods, designed to prevent gas leaks or leakages of electrolyte solutions, explosions caused by high temperatures or short circuits caused by mechanical loads. To this end, the batteries are supplied in special ventilated transport boxes with fire-proof inner packaging. They are kept in these until they are built into the rollers at the very last stage of the manufacturing process.

Spare parts dispatch is a matter of packaging and delivering widely ranging parts as quickly and safely as possible. The spare parts warehouse works completely independently of the Production team and stocks a range of spare parts in a 3,500 m² facility.

The large parts are kept in high-rack storage. From there, cutting-edge high-rack forklift trucks with automatic positioning system remove them at high speed and bring them to the packing stations. The various smaller parts are located in a sophisticated 9 m high warehouse system with 12 vertical lifts. They travel at an impressive 6 m/s from the vertical carriage to the output.

This is how the Service team manages to supply spare parts to branches and customers all over the world from its base in Tirschenreuth, Germany. Hamm places great importance on fast delivery, whereby 98% of all emergency orders are shipped on the same day.

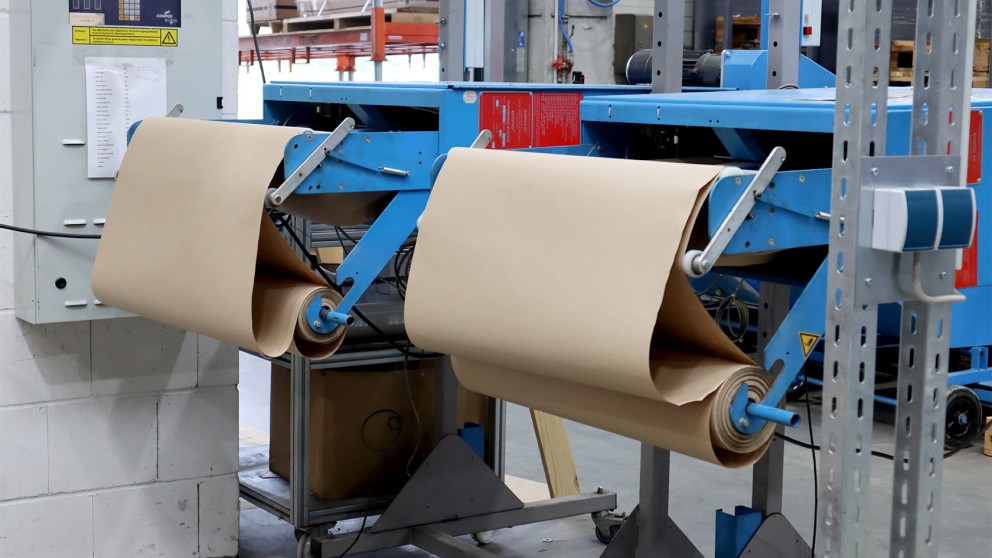

For transportation that is both sustainable and secure, most spare parts are packaged in cardboard. Films and plastic are avoided as far as possible. Filling material and padding is largely made from packing paper; with polystyrene chips considered taboo. If the spare parts are not manufactured in-house, Hamm has the products delivered already prepared for dispatch, so that there is no need to repackage them in new packing material.

Where this is possible, the spare parts are packaged in eco-friendly cardboard and paper.