The Kleemann expertise

Based on their expertise and extensive practical experience, the Kleemann application and process technicians are important contact partners in the company when this involves the new and further development of machines.

Technical innovations and good planning guarantee efficient processes and thus less material and fuel consumption

Many quarriers or recycling companies wish for plants that can be operated economically, but also as sustainable and emission-free as possible. Kleemann here counts on innovative technical solutions and comprehensive consultation with the customers.

The technical solutions related to process optimisation include precise regulating instruments such as the innovative Continuous Feed System (CFS). It ensures that the feed material at the crushers is always conveyed with maximum efficiency through the machines. The fill level of the crushing chamber is monitored continuously and the feed is adapted to the process. This optimised process ensures that material wear is as low as possible. Furthermore, the fuel consumption is also reduced – both of which are good for the environment.

The CFS feed control guarantees a trouble-free process. The system checks that the feed material at the crushers is always conveyed with maximum efficiency through the machines.

The Continuous Feed System (CFS) is an example of how the complete process can be optimised by intelligent technology. Technical innovations, however, are only building blocks. Good planning of a plant train is just as important, if not more. Technical innovations can only fully demonstrate their strengths when all components closely mesh with one another.

To work effectively and thus in a resource-conserving manner, the plant must be neither too small nor over-dimensioned. The selection of the crushing plants with the matching crushing tools is thus decisive, and the screening plants – equipped with the ideal screening media – must be well tuned to the process. Stockpile conveyors that offer a capacity that matches the complete plant must be provided and consideration of the capacity of the loading device belongs to the overall process.

If machines are set accordingly, the power consumption can be reduced many times over. A process optimised in this manner also means that wear is reduced to an absolute minimum. This is also an important point because if components wear quickly, new components have to be produced with a high material and energy input. Avoidance of unnecessary wear therefore not only help saves money, but also reduces CO₂ emissions to a considerable extent.

Based on their expertise and extensive practical experience, the Kleemann application and process technicians are important contact partners in the company when this involves the new and further development of machines.

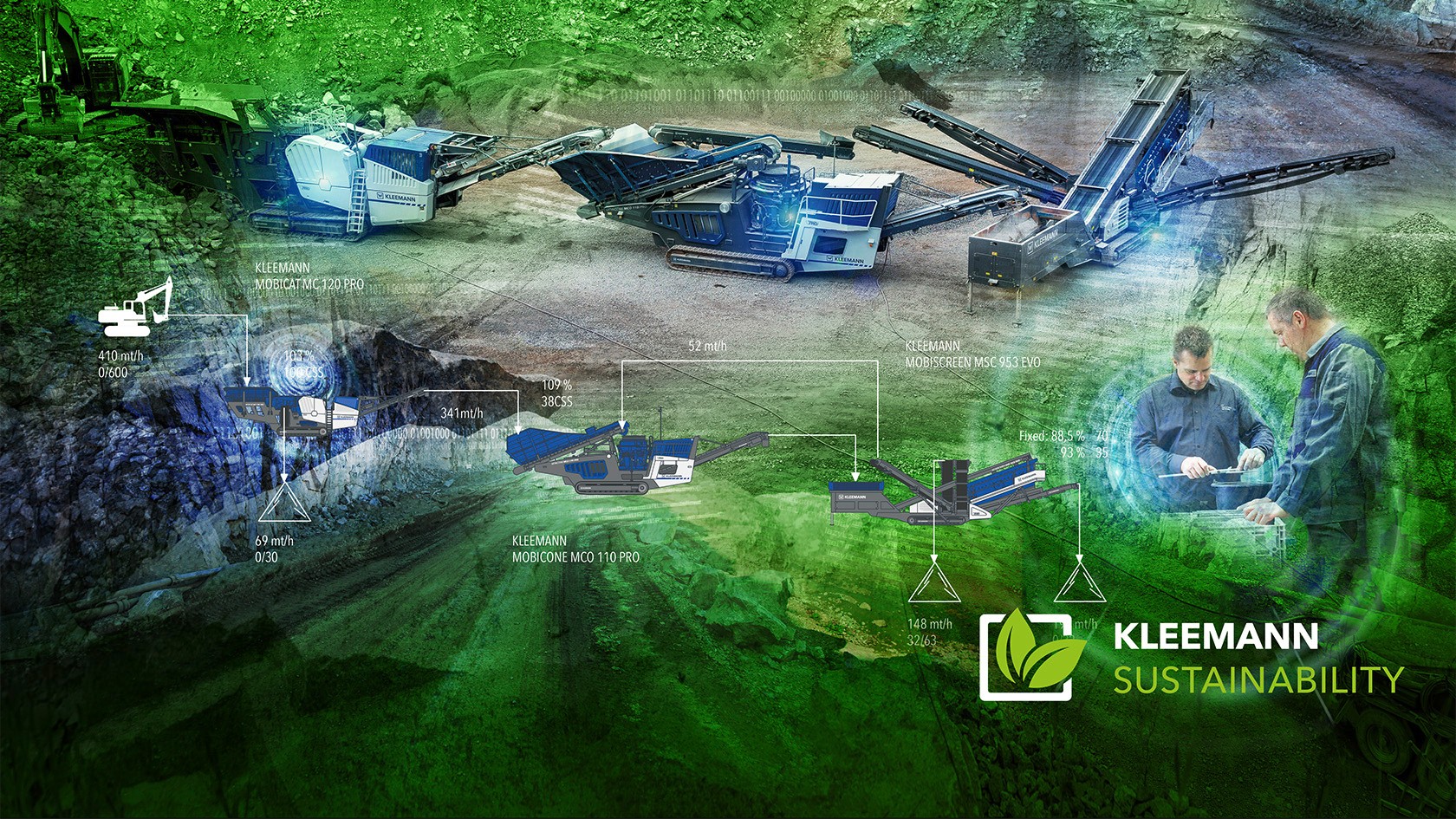

In this area, Kleemann relies on comprehensive consultation with the customers. Application advisers plan all processes in advance. In the case of extensive processes, a flow chart (AggFlow) is prepared with which the material flow can be simulated in detail. The consultation covers technical solutions but also information on how processes can be better organised. The custom-fit engineering of a plant train requires good planning software, but also a lot of experience and sure instinct. Kleemann therefore relies on technical solutions and support from experienced application technicians who are present during the implementation.

A flow chart demonstrates what the plant can produce by means of simulation. Fuel-saving and resource-conserving operation requires the best possible interaction of all components.

Press/media kit

Click here to download a ZIP file containing the press release in the available languages in Microsoft Word format and the images in 300 dpi resolution.

Download