Intelligent line coupling for crushing processes

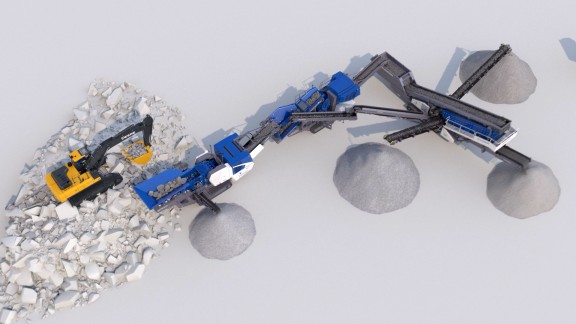

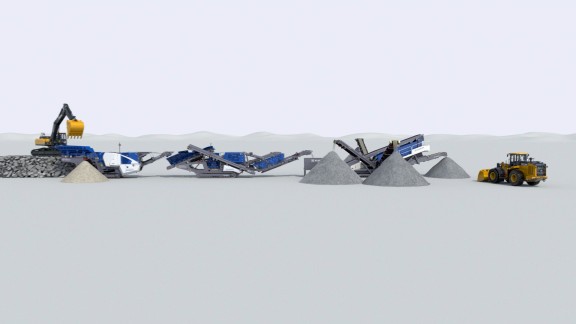

In many natural stone applications, several crushing stages are required. The number of crushing stages depends on the type and size of the feed material and the desired end products. The plants can be coupled together using the line coupling option. A distinction is made here between process coupling and safety coupling.

Process coupling

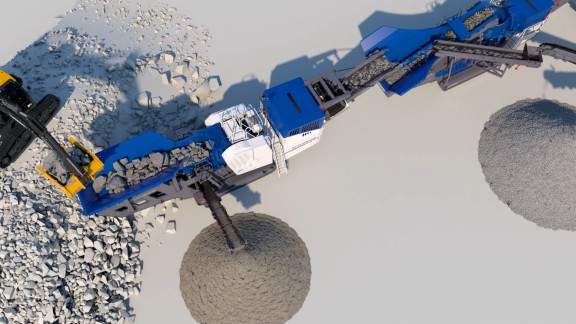

KLEEMANN machines can be linked together via the intelligent line coupling. The crushing process between the crushing plants is automatically optimised so that the material is always conveyed through the machines with maximum efficiency. For this purpose, a probe is installed on the crusher discharge conveyor and/or fine grain conveyor of the upstream machine, which monitors the fill level of the feed unit of the downstream machine. If the fill level reaches a defined, adjustable level, the production output of the upstream machine is temporarily reduced.

Safety coupling

If an emergency stop button is pressed on the plant train in the event of an emergency, all machines are safely stopped. This is guaranteed by the safety coupling of the plants. For this purpose, apart from the cable connection new technology is also available: coupling via a radio system. The "Wireless line coupling" is easier to handle and makes the typical workday of the operator easier. Complex cable routing is no longer necessary and easy conversion of the plants is also possible.

Thanks to the intelligent line coupling from KLEEMANN, overload situations and damage are prevented. All of this combined results in a high availability and output with low wear.

Wired line coupling

For safety reasons, all crushing and screening plants are linked by cables. If an emergency-stop button is pressed somewhere on the plant, all machines are stopped safely.

Wireless line coupling

For safety reasons, all crushing and screening plants are linked viaa radio system. If an emergency-stop button is pressed somewhereon the plant train, all machines are stopped safely. Easy handling and convenience for the user: no cables need tobe laid, machines can be easily adapted.

Feed control for an optimised material flow

The crushing process of the KLEEMANN crushing plants is optimised automatically by the innovative feed control CFS (Continuous Feed System) so that material is always conveyed with maximum efficiency through the machines. At the same time, the filling level of the plant's crushing chamber is monitored. When the filling level reaches a height that can be defined in advance, the material feed of the machine is adjusted. This system forms the perfect basis for the line coupling of an interlinked plant train.

CFS - Feed control for an optimised material flowApplication examples of line coupling

Due to their complexity, system hoists must always be planned precisely in advance in order to achieve optimum results, low wear and the best sustainability. The Kleemann application experts will be happy to support you.

We are happy to helpWhat end result does a plant deliver? What output level can be expected? Are the individual elements of a plant train perfectly tuned to one another? A new plant has to be well planned and forms the basis of productive work. To find the correct answers to this is the core competence of Kleemann Application and Process Engineering.

Go to THE ROCK