Cutting technology

The goal of every construction project is the achievement of high-quality results.

This applies to the use of cold milling machines and cold recyclers in road rehabilitation as well as in soil stabilisation and the extraction of valuable mineral resources with Surface Miners.

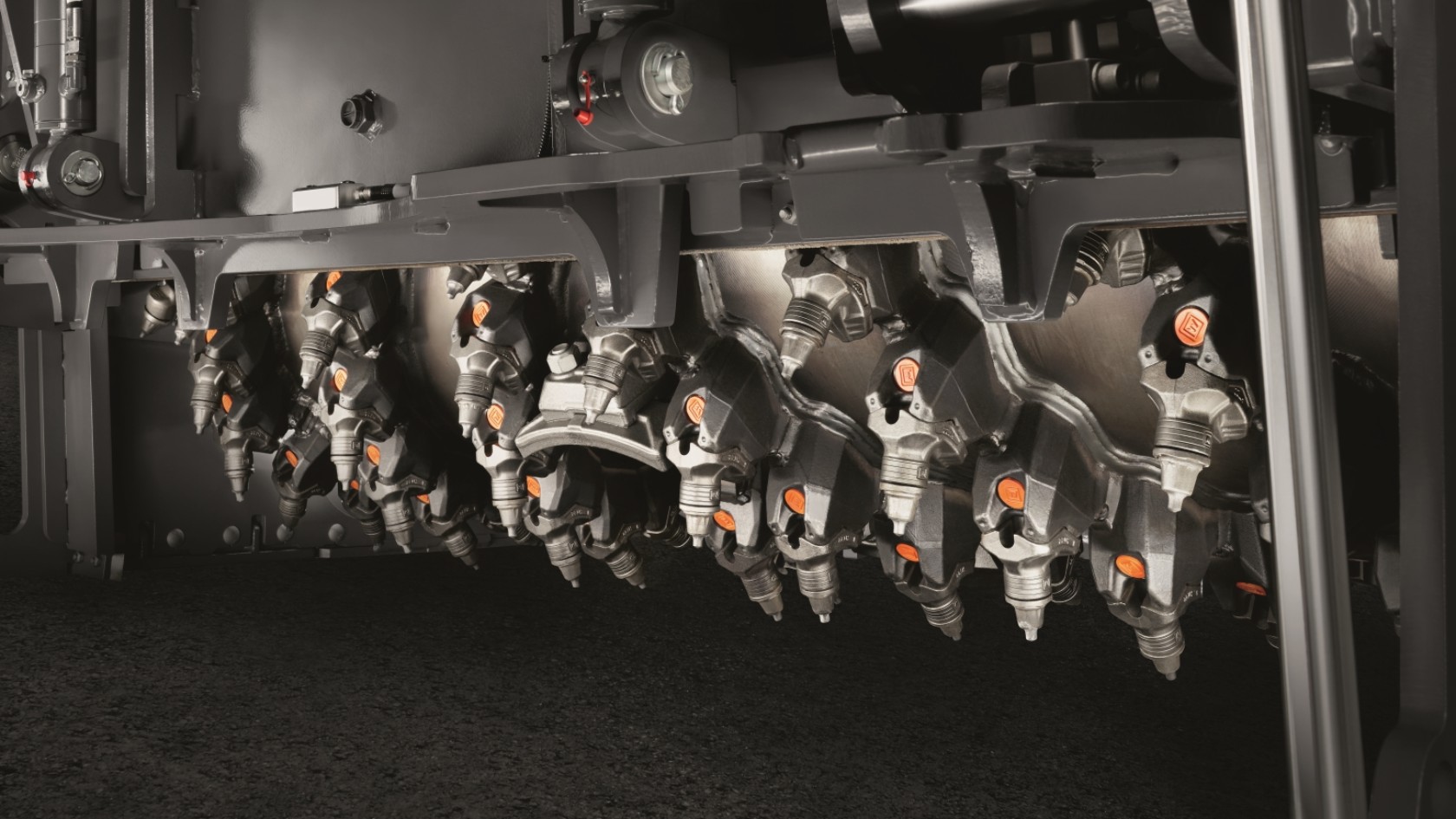

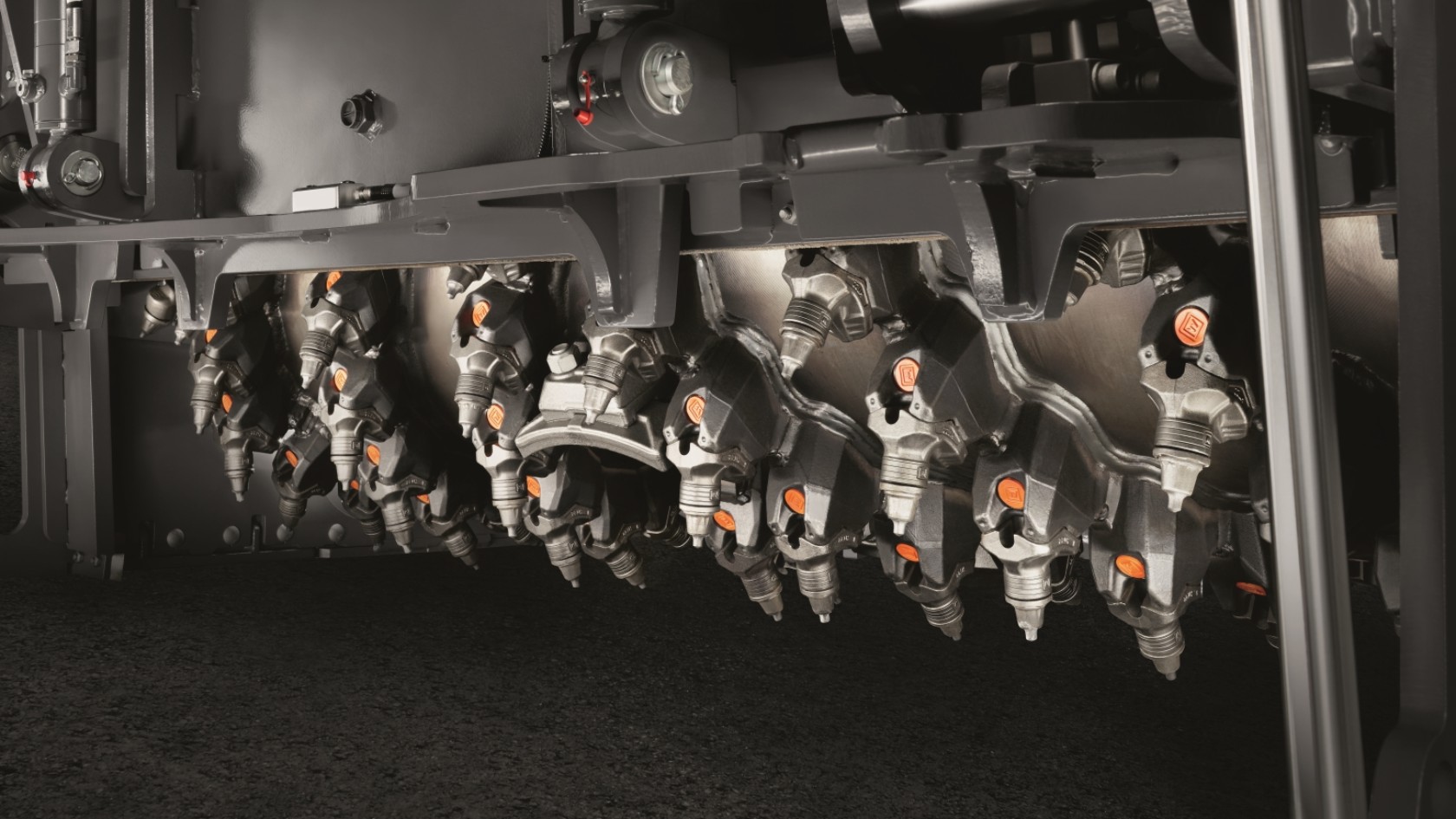

Ideal interplay between the milling drum, the toolholder and the picks is essential for precise and efficient removal of pavement layers.

WIRTGEN is the market leader in cutting technology, and offers its customers perfectly matched, high-performance cutting systems. In addition, WIRTGEN is continually revising and improving all components of its cutting technologies. This process is above all driven by practical experiences in the field and feedback from customers.

During the milling process, round-shank picks and cutting tools break up the surface and granulate it into small pieces of reusable material.

> Round-shank picks and cutting toolsTwo decisive factors for precise and productive milling and cutting are absolute stability and the wear resistance of the cutting tools. In the rugged WIRTGEN toolholder systems, the picks are always firmly anchored.

> Toolholder systemsWIRTGEN offers an extensive selection of milling drums that enable our customers to realise numerous different applications in road pavement processing and recycling scenarios, or in cutting processes for the extraction of soft and hard rocks, stone and minerals.

> Milling and mixing rotors and cutting drums