Intelligent ballasting – optimum compaction quality thanks to even weight distribution

Depending on the type of asphalt and layer thickness, or the earthworks to be performed, correctly ballasting the pneumatic tyre rollers is key to achieving high quality compaction. HAMM offers a flexible ballasting concept for the HP series of pneumatic tyre rollers (Tier 3, Tier 4) – quick and easy to use on the construction site, it enables optimal weight distribution to guarantee the best possible compaction results.

The HP series ballasting concept at a glance:

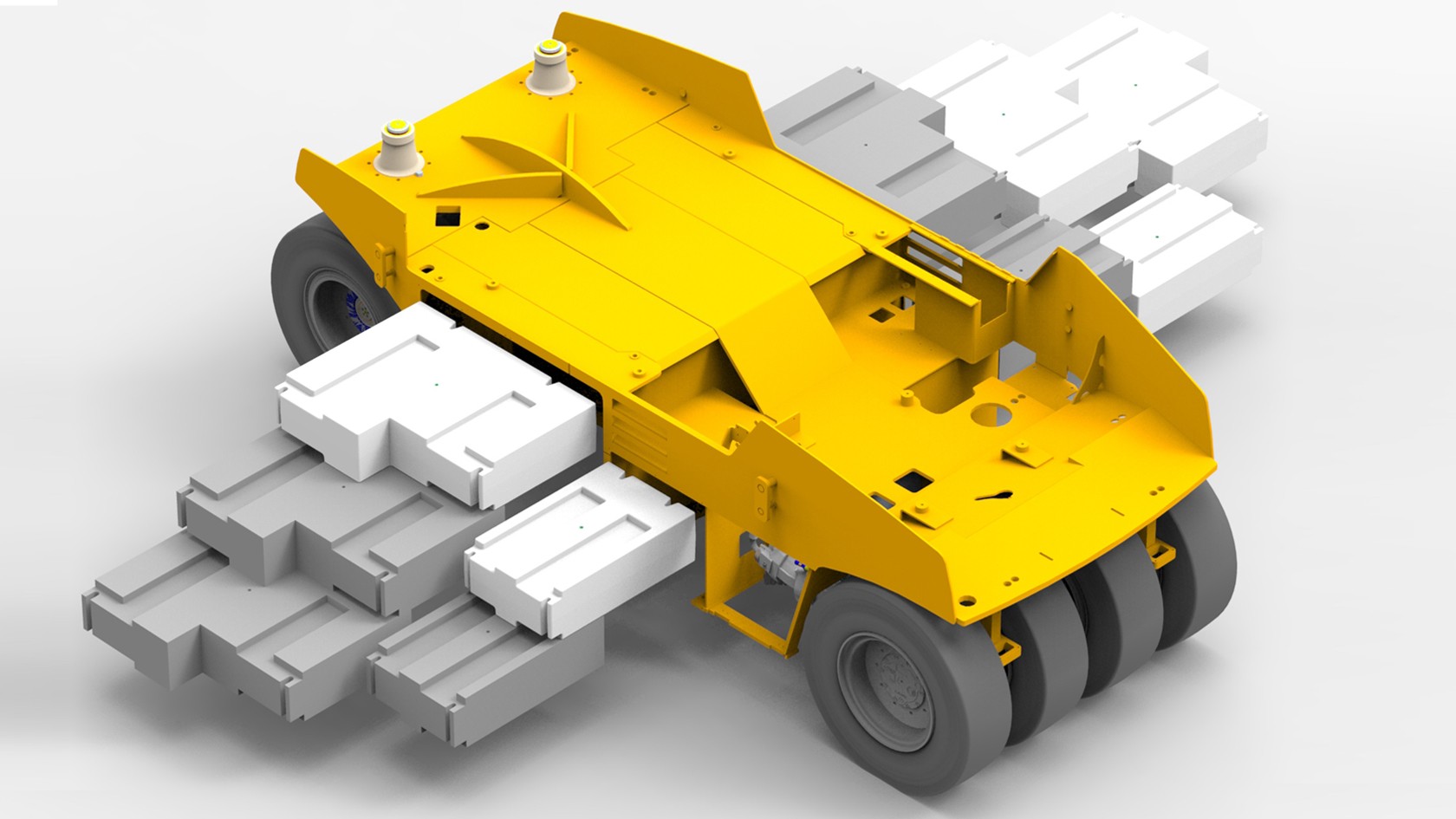

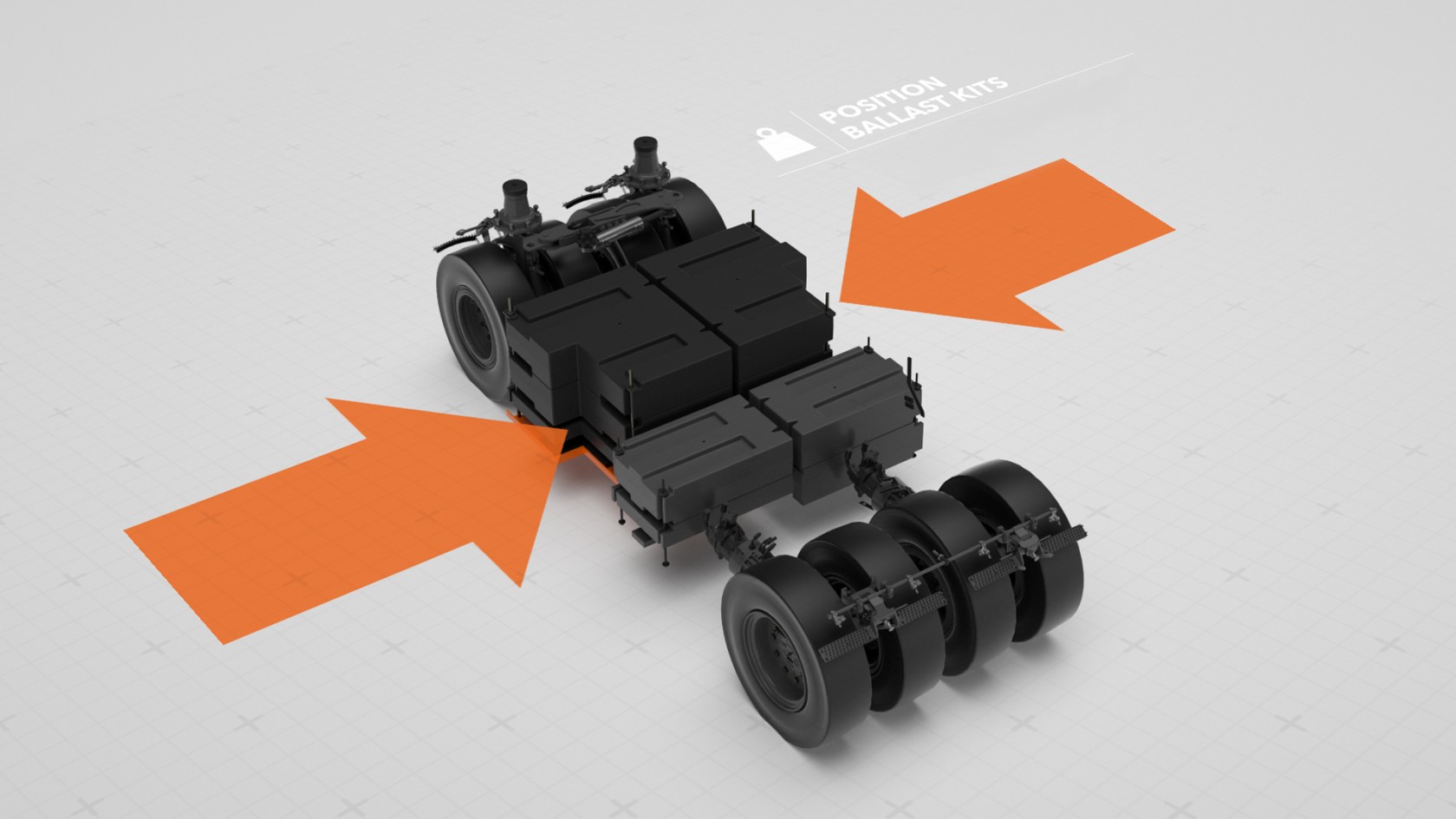

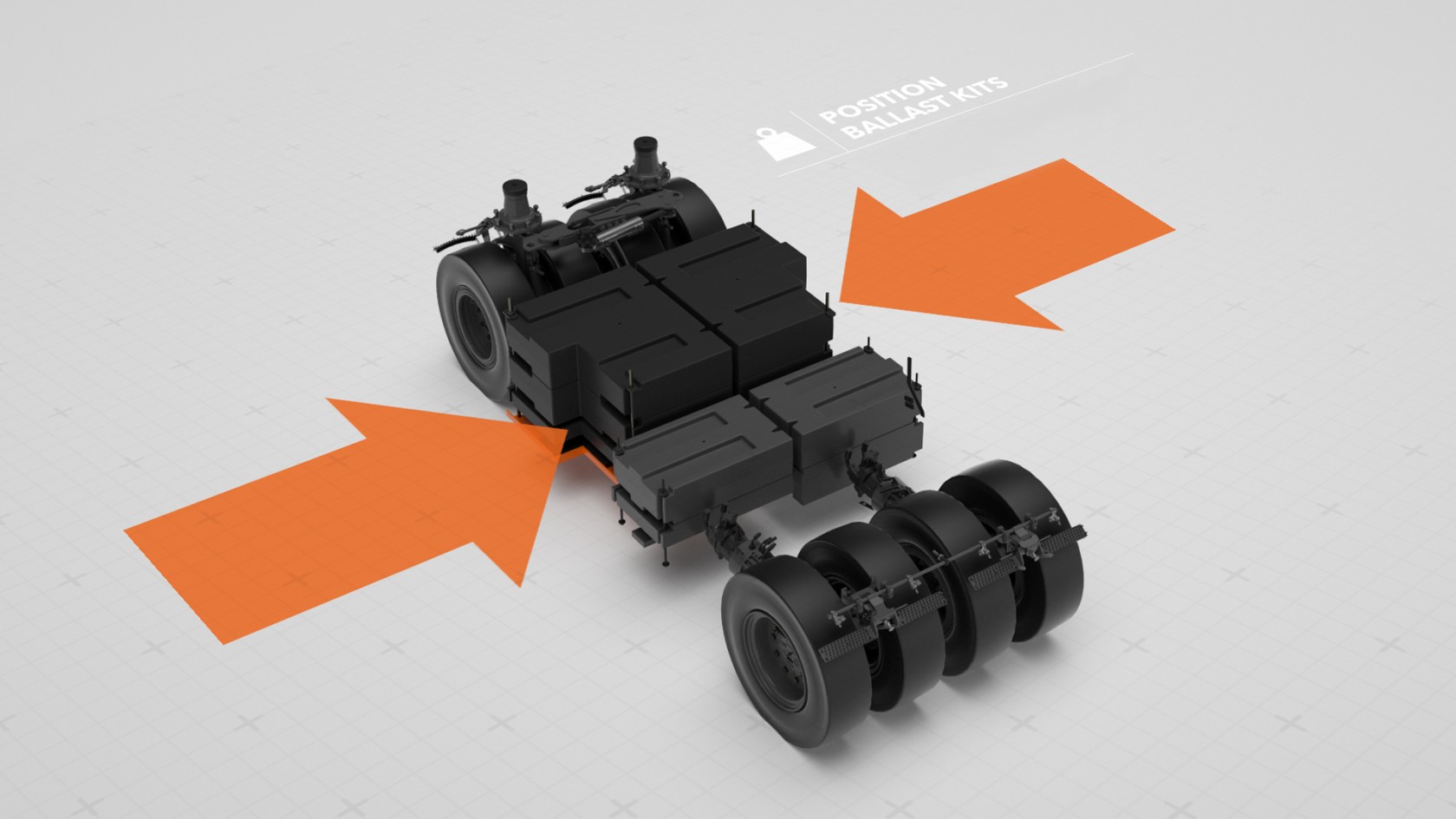

The basis for ballasting the models from the HP series is the two large ballast spaces between the wheelsets. Here, pre-made ballast bodies made of steel, heavy concrete or concrete can be inserted or removed using a forklift truck, for instance. A range of precisely manufactured ballast bodies are available ex works. Optionally, HAMM offers a model with a ballast space measuring 2 m³ for both markets. This can be used for self-ballasting (e.g. using scrap or sand). The ballast space can be filled with this material via filling openings on the right and left of the machine. For all models in the HP series, there is also an optional additional water tank with a volume of 1,500 litres. This can be used as a water reservoir to supply other rollers, as an extension of the regular water tank for tyre sprinkling or as additional weight. For models in the HP series, this means that the weight of the basic machine can be adjusted by up to 10 tonnes (HP 180, HP 180i) or 18 tonnes (HP 280, HP 280i).

The different ballasting variants therefore allow for a high degree of flexibility when selecting the wheel load, which, alongside the inner tyre pressure and roller speed, is key to compaction force and depth. Depending on the equipment and ballasting of the pneumatic tyre rollers, the wheel load per tyre can be adjusted between 1 tonne and 2.3 tonnes (HP 180, HP 180i) or between 1 tonne and 3.5 tonnes (HP 280, HP 280i) to best meet the requirements of the task at hand.

The advantages of the ballasting concept:

Pneumatic-tyre roller

| Weight | 9,480 kg |

| Drum width | 1,830 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |

Pneumatic-tyre roller

| Weight | 8,505 kg |

| Drum width | 1,830 mm |

| Exhaust emissions category | EU Stage IIIA / EPA Tier 3 |