Correct handling pays dividends.

In order to receive a constant high material volume from a cone crusher with high final product quality, mobile cone crushing plants should be operated in the optimum range. With KLEEMANN cone crushers, high process reliability is already assured in the factory. Users can additionally optimise the crushing process with the application expertise of KLEEMANN. This starts with the selection and composition of the correct tool, which consists of cone and bowl liner.

For tough tasks: mobile cone crushing plants in the MOBICONE series

As all other KLEEMANN plants, the mobile MOBICONE cone crusher are characterised by a high output, low consumption and a well-thought-out machine concept.

In addition, KLEEMANN subdivides its product portfolio into two lines: EVO and PROThe MOBICONE EVO plants are extremely versatile, easy to transport, have short set-up times and a high machine availability. The MOBICONE PRO crushing plants are ideal for the demanding work in a quarry. For this purpose, they are particularly robust and low-maintenance, very efficient and make pure electric operation by an external power supply possible.

An important common feature of the MOBICONE PRO and EVO Line: the tools of the crushing unit are available in different designs and qualities. The use of the correct tool is the key to a high-quality final product and for an hourly output that is as high as possible.

MOBICONENote for practical use:

The difference in the crushing stage is defined by the final product. This means: the secondary application with the cone crusher can be defined roughly based on the final products of 25–80 mm. The tertiary application roughly includes all final products <25 mm.

Tip for practical use:

The following can be recommended as a rough rule of thumb: XPERT for medium-abrasive applications and XTRA for highly abrasive applications, whereby the wear behaviour is very strongly dependent on the material properties, moisture level and the content of fines.

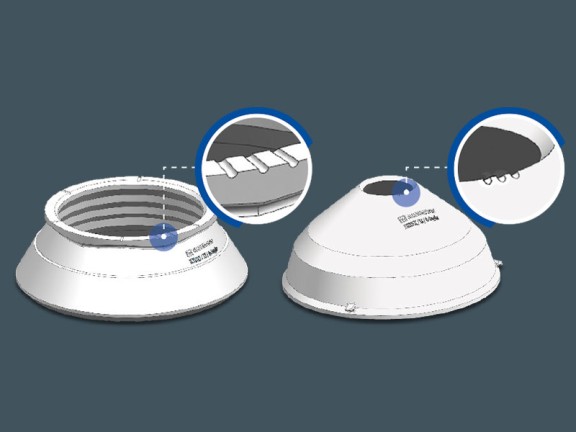

How can Standard and Short Head be recognised?

Once the tools are installed, they can no longer be distinguished from one another based on their shape. KLEEMANN therefore uses markings on the cones and bowl liners.

Depending on the size of the cone crusher and the feed material, the following factors are decisive in the selection of the crushing tools:

The feed opening (CFO = Closed Feed Opening)

The minimum gap width (CSS = Closed Side Setting)

Ask your application expert!

Long-term and constant applications can be analysed in detail and optimised if necessary. KLEEMANN application experts and Customer Support will be glad to advise you and can provide support with installation and removal of the tools.

Contact

Public Relations

Reinhard-Wirtgen-Straße 2

53578 Windhagen

Germany