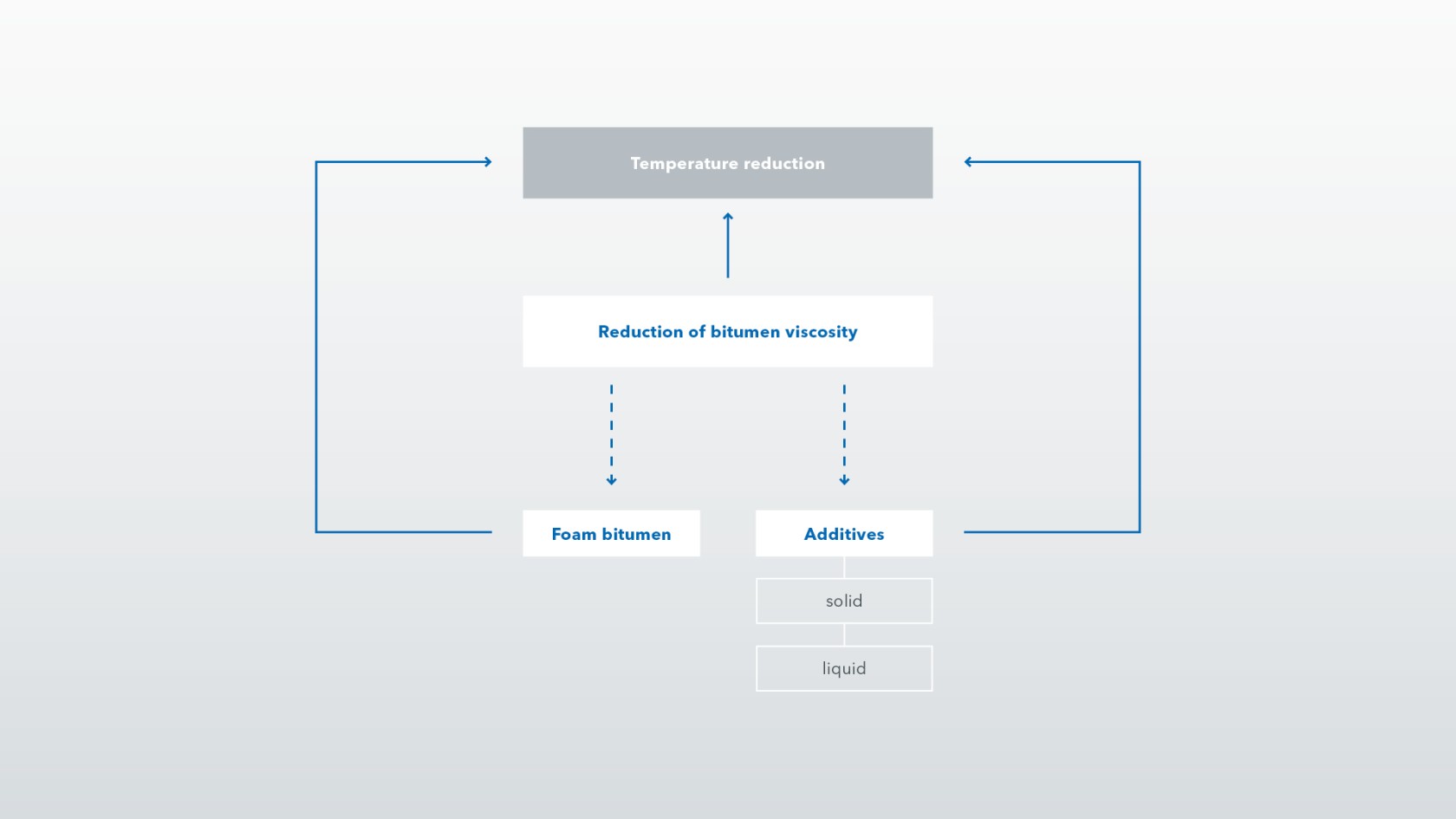

The pivotal point: reducing the bitumen viscosity

The bitumen requires a temperature of at least around 140 °C to achieve good wetting and coating of the aggregates in the mixer. Below this temperature, it is too viscous. To lower the temperature during asphalt production, the bitumen viscosity has to be reduced temporarily. This is achieved by adding water (foam bitumen) or additives.

When the hot bitumen is mixed with water, the resulting water vapour expands suddenly – the bitumen foams and the volume increases manifold. This larger surface allows for better wetting of the aggregates in the mixer. This means that the mineral is coated well even at a lower temperature. Another option for lowering the bitumen viscosity is to add solid or liquid additives.

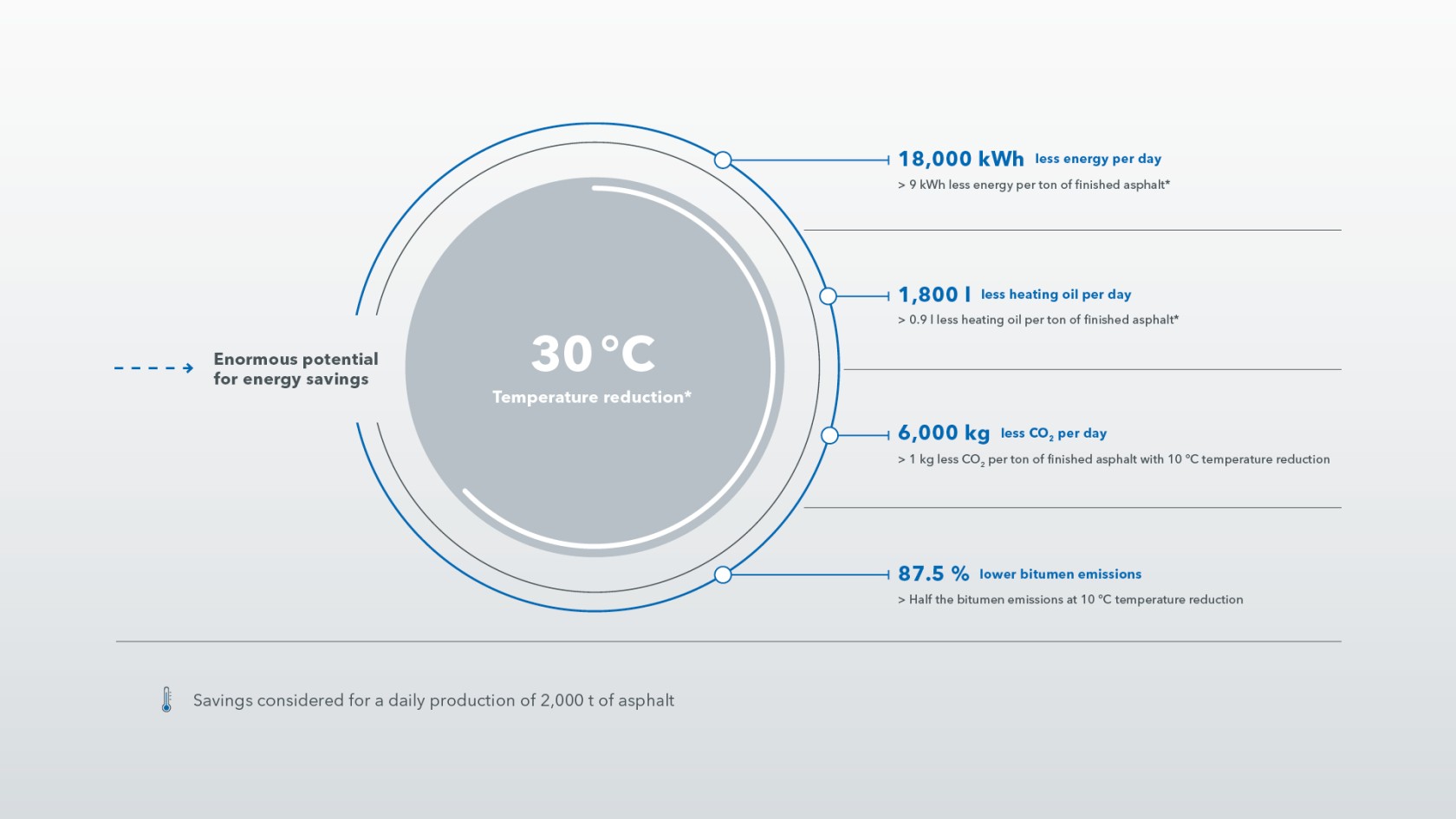

Substantial energy reduction

A comparison of the temperature level during the production of hot asphalt, temperature-reduced asphalt and cold asphalt shows that the temperature can be reduced by up to 40 °C by using foam bitumen, ensuring a high mixture quality even in the range between 110 and 130 °C. At the same time, energy consumption and CO2 emissions are also significantly reduced.