The paving crew is already used to the operating concept of the Wirtgen SP 62i and feels at home on the machine. The machine has been in use on a number of other paving projects and, in the meantime, has clocked up quite a few operating hours. For instance, around a year ago in the Southern Pointe Community:

Read the press release about the compact SP 62i Slipform Paver

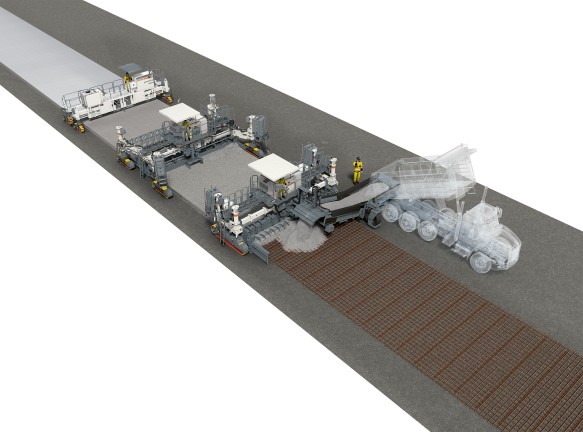

The professionals from Larry Young Paving Inc. were positively impressed after their first encounter with the new placer/spreader. ‘We were already familiar with the basic operating and control concept of the WPS from the Paver’, says Ronnie Carter, Assistant Project Manager at Larry Young Paving Inc. The short training period on the machine saves time and money, and paving can begin almost right away. The paving crew was also impressed by the remote control for height adjustment of the WPS strike-off wall. This enables the operator to conveniently adjust the height of the placed concrete, for example from onboard the Paver. This function was, however, not introduced solely for the sake of convenience, it also contributes to perfect paving results. At the same time, it enables the operator to easily monitor and assess the filling level in the compaction compartment and the quantity of concrete placed and spread from onboard the Paver.