Mixed-in-plant process

When mixing in-plant, reclaimed asphalt pavement and crushed stone are transported to a mixing plant located in the vicinity of the construction site. Here the milled material is mixed with binders to produce a new construction material mix which is reused either on the same or on a different construction site.

In-plant processing becomes attractive when:

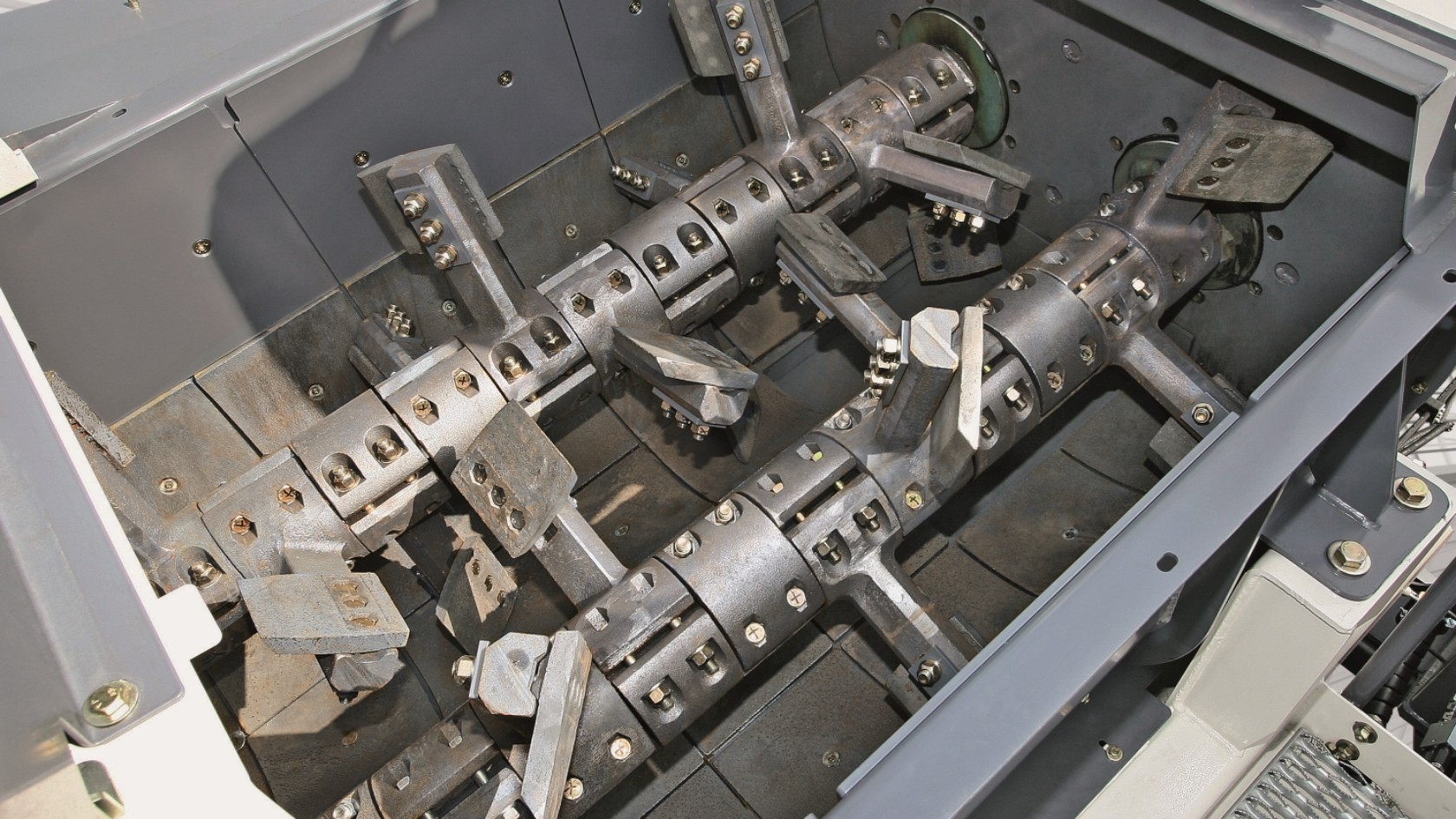

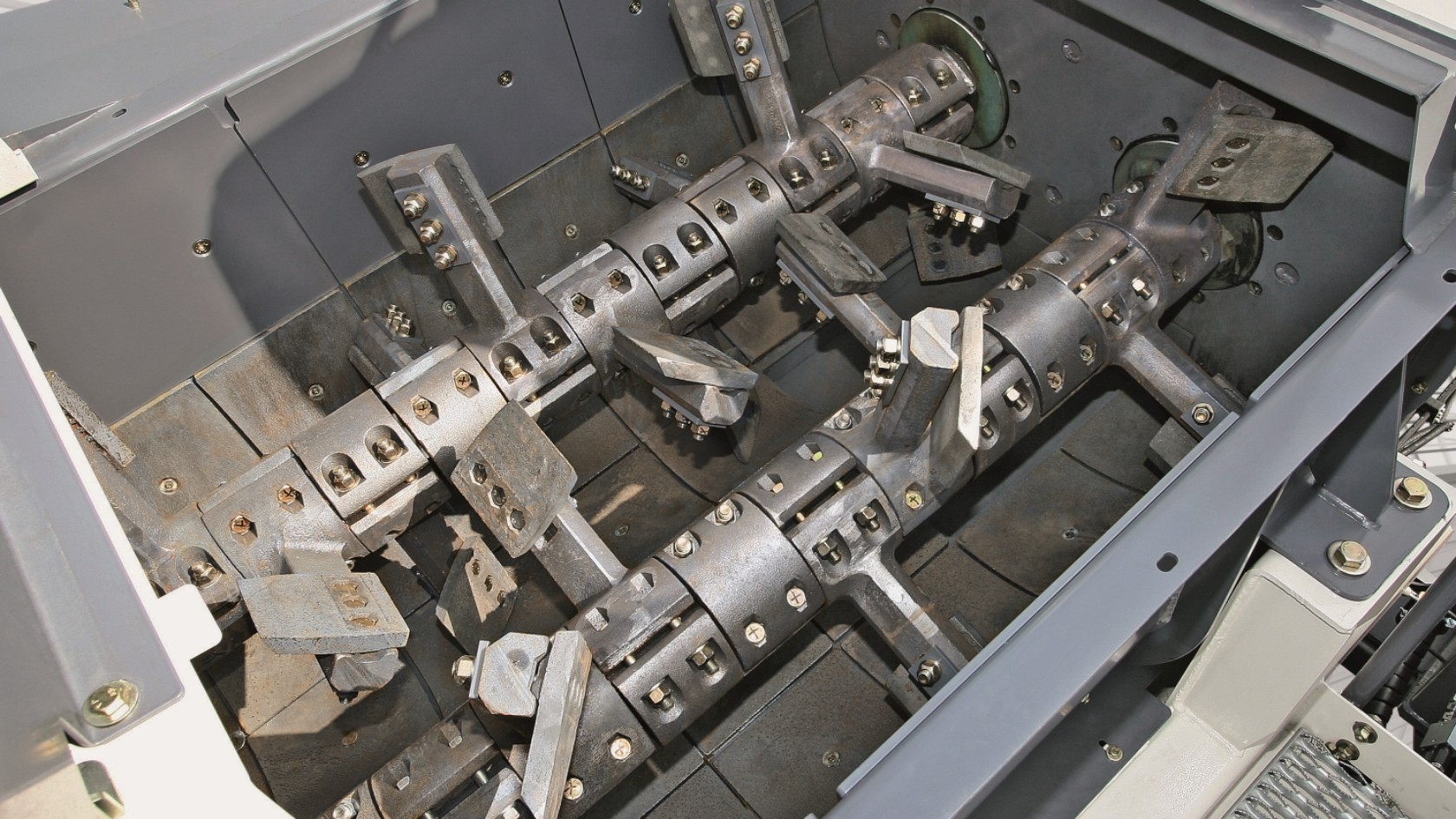

The mobile KMA 220 / KMA 220i cold recycling mixing plant is equipped with a powerful twin-shaft compulsory mixer to produce fully homogeneous recycled mixes. The mixer is fitted with mixing arms and mixing blades arranged in a specific pattern and manufactured from highly wear-resistant carbide metal. The mixing vessel is lined with special wear plates.

The mixing blades and interior of the compulsory mixer are manufactured from highly wear-resistant material. The mixing blades allow independent adjustment and can be replaced individually. All plant components, including the mixer, are driven hydraulically via a powerful diesel engine. The robust twin-shaft continuous mixer is undoubtedly a highlight, having a homogeneous mixing capacity of 220 tonnes per hour.