Technology: Surface Mining

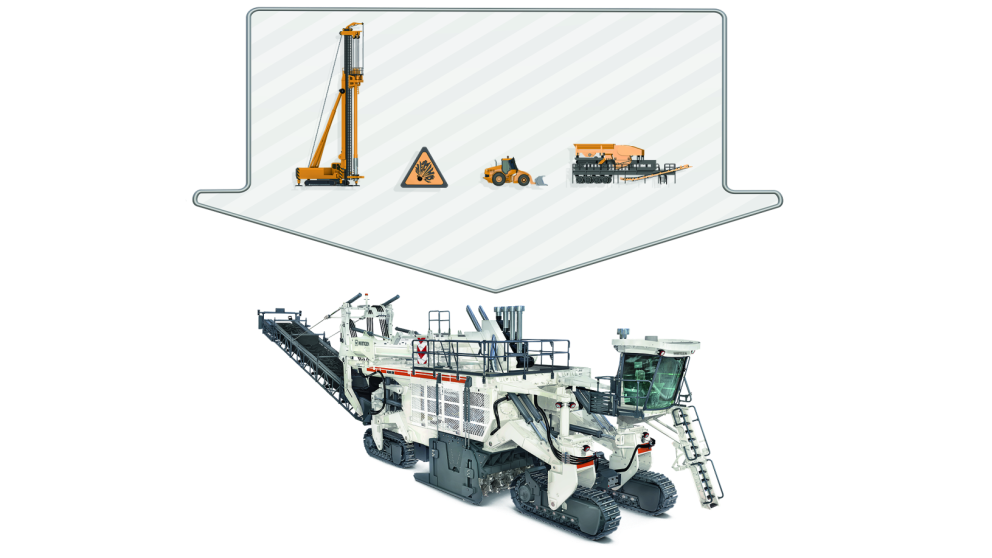

Our know-how in mature cutting technology permits deposits to be mined selectively and without drilling and blasting. The method is environmentally friendly and yields useful minerals of the purest quality!

Become acquainted with the operating principle and technical components of the surface mining technology. Get to know our state-of-the-art cutting technology, and learn more about new methods in the mining of useful minerals.

As the surface miner moves forward, a special cutting drum rotates against the direction of travel, cutting layers of material from the rock formations and crushing it in the process. The primary conveyor picks up the material in the drum housing and transports it towards the rear of the machine, where it is then accepted by the slewable and height-adjustable discharge conveyor. The discharge conveyor loads the material into trucks or dumpers or discharges it to the side of the miner. The discharge height can be adjusted to the height of the transport vehicles. The surface miner is driven via four steerable and height-adjustable track units. An automatic levelling system ensures precise adherence to the cutting depth, thus enabling even thin seams or layers to be mined selectively and with maximum accuracy.

Surface miners are just one step in a whole process chain but have a vital influence on the entire process – and in particular on the final result. The following features are the hallmarks of this innovative method:

Cutting crushing and loading in a single operation

The mining material is cut, crushed and, if required, loaded straight into trucks or dumpers in a single operation, thus dispensing with conventional primary crushing in an additional work step. The surface mining process is much more economical than standard drilling and blasting methods with subsequent material loading.

Selective mining

Surface miners extract primary resources in a selective operation, achieving high degrees of purity and maximizing exploitation of the deposits. Selective mining considerably reduces equipment, labour and time requirements as well as overburden volumes.

Blasting is avoided, stable surfaces are created

Strict environmental standards in terms of noise and dust emissions make the vibration-free surface mining process attractive in comparison to drilling and blasting. The stable, precise and level surfaces produced in mining, earthworks and rock operations are suitable for immediate use as pavements, slopes or tunnel floors.

Minimized environmental impact

We not only develop innovative machines of the highest quality. With our machine technology, we also constantly endeavour to keep environmental pollution as low as possible. A WIRTGEN surface miner is a perfect example of this philosophy: it impresses with its environmentally friendly technology as it cuts, crushes and loads rock in a single operation. A tremendous advantage of selective mining is that the vibrationless mining operation without drilling and blasting is accompanied by low levels of dust and noise. The low environmental impact also permits maximum exploitation of the deposit right up to the edge of residential areas. The selective mining of high-quality materials requires considerably less space than conventional mining methods. Our fuel-efficient, intelligently controlled engines comply with the strictest exhaust emission standards.

WIRTGEN is global market leader in the manufacture of machines for cutting rock in opencast mining operations. WIRTGEN surface miners cut primary resources such as coal, gypsum, iron ore, salt, phosphate, bauxite, limestone or granite, achieving high degrees of purity in the process. They are increasingly used as primary extraction equipment also in newly opened-up opencast mines or extensions of existing opencast mine operations.