Split drum – the key to premium quality

Increasingly tough demands regarding the quality and cost-efficiency of road construction measures have led to growing demand for machines and technologies that are designed for specific applications. One example are split vibration and oscillation drums. HAMM offers these for tandem rollers in the HD+ series (split vibration drum) and HX series (split vibration drum and/or split oscillation drum).

The split drum at a glance:

When negotiating corners and roundabouts and when performing tight steering manoeuvres, attempting to perform compaction without twin drums can lead to material being displaced and cracks forming on the surface. A split drum prevents this from occurring as the two halves rotate at different speeds. This minimises shear stress on asphalt, which prevents the material from being displaced and prevents cracks from forming. When compacting asphalt types that are particularly susceptible to being displaced, such as stone mastic asphalt or polymer-modified mixed material, this characteristic is a key factor affecting the compaction quality.

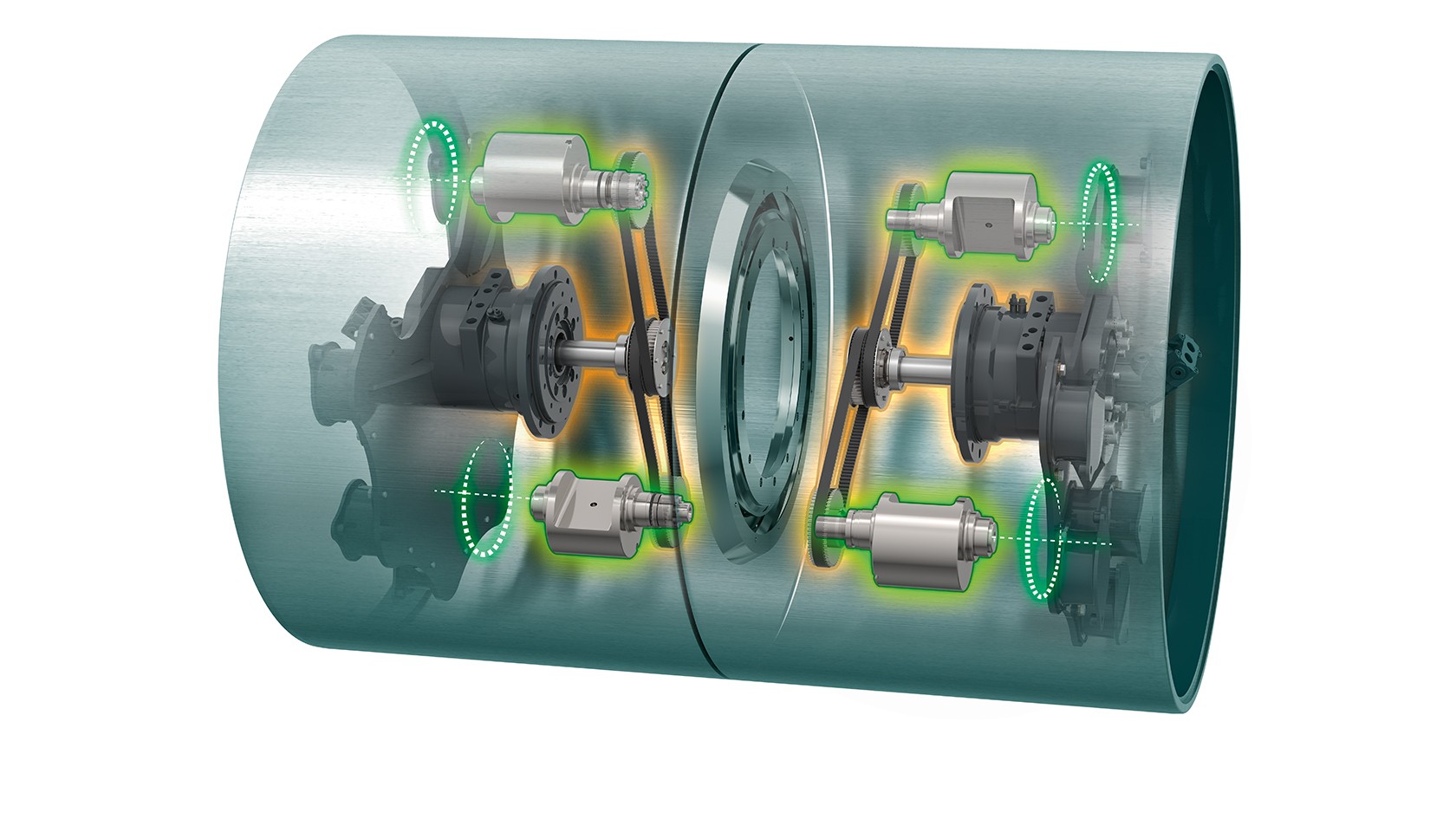

The split oscillation drum from HAMM at a glance:

HAMM has combined these benefits with the advantages of oscillation and developed a split drum with oscillation. In this solution, each drum half contains a separate, mechanically independent oscillation unit. An integrated control system can therefore be used to adjust the position of the unbalanced masses quickly and precisely to suit the position of the drum halves. The two halves are synchronised by innovative digital hydraulics. This ensures that the two drum halves oscillate synchronously at all times, despite the difference in their rotational speed.