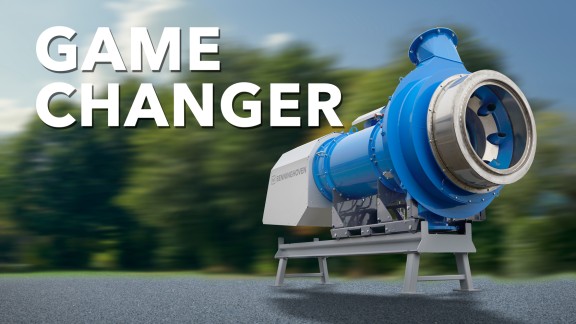

MULTI JET burner changes fuels

New Benninghoven burner generation now available as a standard product

The new burner generation from Benninghoven uses up to four different fuels, regardless of their physical state – whether solid, liquid or gaseous. Crucially, this also includes the use of hydrogen as a sustainable, pioneering energy source.

On-the-fly fuel changes with mixed use of fuels without downtime

One feature of the MULTI JET burners is the use of mixed fuels, allowing the simultaneous use of hydrogen, LPG, HVO, biogas and natural gas. Separately positioned nozzles enable optimum combustion of each individual substance. Fuels can be switched on the fly, without shutdown or downtime. This system ensures a reliable supply with different fuels, offering plant owners a high level of flexibility when selecting the most cost effective and most readily available energy sources.

Benefits in terms of noise, output and prices

In addition to the reduction of CO₂ emissions, Steven Mac Nelly, Head of Development & Design Engineering at Benninghoven, points out other benefits of the new burner generation: “Noise emissions of the new burner generation were reduced by 5 dB(A), which corresponds to cutting the perceived noise level in half. Furthermore, the electrical power consumption was reduced by 20 % while maintaining the same feed capacity.” Compared to fossil fuels, hydrogen will offer a significant price difference in the future as there are no taxes levied due to the absence of CO₂ emissions. “Countries such as the Scandinavian nations and Switzerland are already feeling the impact of stricter CO₂ pricing for fossil fuels,” says Mac Nelly.

Flexible use of hydrogen from different sources

Benninghoven has developed a coordinated complete solution for material drying. For the first time, this enables customers to use up to 100 % green hydrogen in ongoing operation. The hydrogen drying system consists of the multi-fuel burner, a burner control, a feed system with a patented pressure control section, which reduces the hydrogen for the burner from 350 bar to the required 1.3 bar, as well as other plant components that are specifically adapted to the use of hydrogen. The complete solution connects directly to the hydrogen source – flexibly from different units such as trailers, pipes or remote electrolysers.

A safety concept is required for the use of hydrogen. This is designed by the Benninghoven experts together with the customers. In addition to reducing CO₂ emissions, monitoring NOx emissions is also crucial. The Benninghoven system includes an exhaust gas recirculation that ensures lower NOx emissions.

Standard product also available as a Retrofit solution for third-party plants

The new burner generation is suitable not only for new Benninghoven plants, but also as a retrofit option for existing plants. The burner can be integrated into existing plants regardless of their origin, ensuring virtually emissions-free asphalt production. Thanks to the flexible options – depending on the availability of the fuels, location or application – the production processes can be sustainably optimised already today, as the MULTI JET burner is now available to plant owners as a standard product.

Public Relations

Reinhard-Wirtgen-Straße 2

53578 Windhagen

Germany

Whether a Benninghoven or third-party plant, with a BENNINGHOVEN Retrofit you can remain or get back to state of the art.

Transportation asphalt mixing plant

| Nominal mixing capacity | 100 - 320 t/h |

| Hot bin section | 17 - 87 t |

| Recycling | up to 70 % recycling |

Transportation asphalt mixing plant

| Nominal mixing capacity | 160 - 320 t/h |

| Hot bin section | 60 - 150 t |

| Mixed material loading silo | 0 - 517 t |

Recycling plants

| Recycling | up to 100 % recycling |

| Nominal mixing capacity | 320 - 400 t/h |

| Hot bin section | 80 - 320 t |