Cutting tools for milling machines

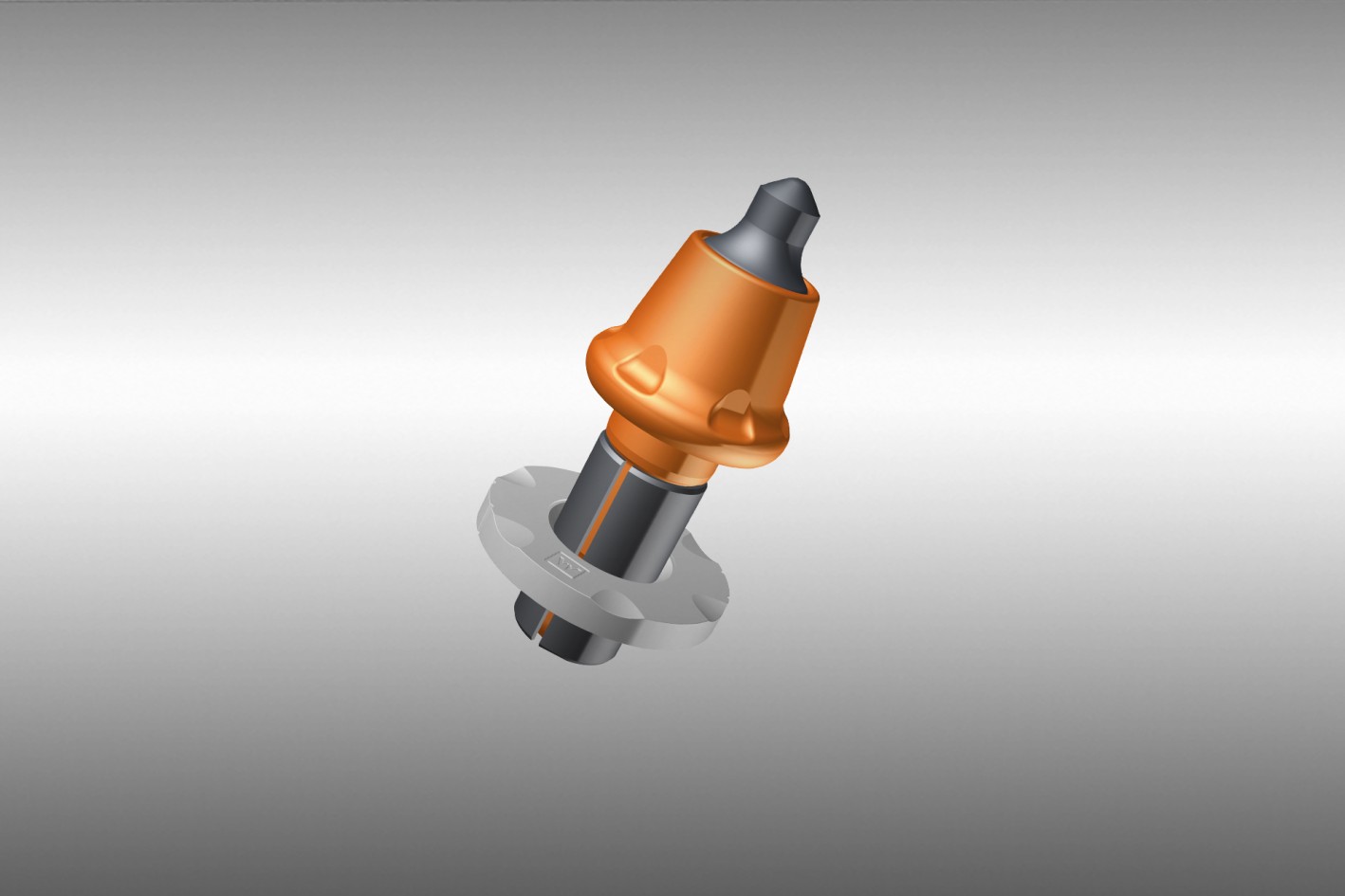

The all-rounder among picks for cold milling, GENERATION A² impresses thanks to its exceptional product features such as the optimised wear plate with its unique groove profile.

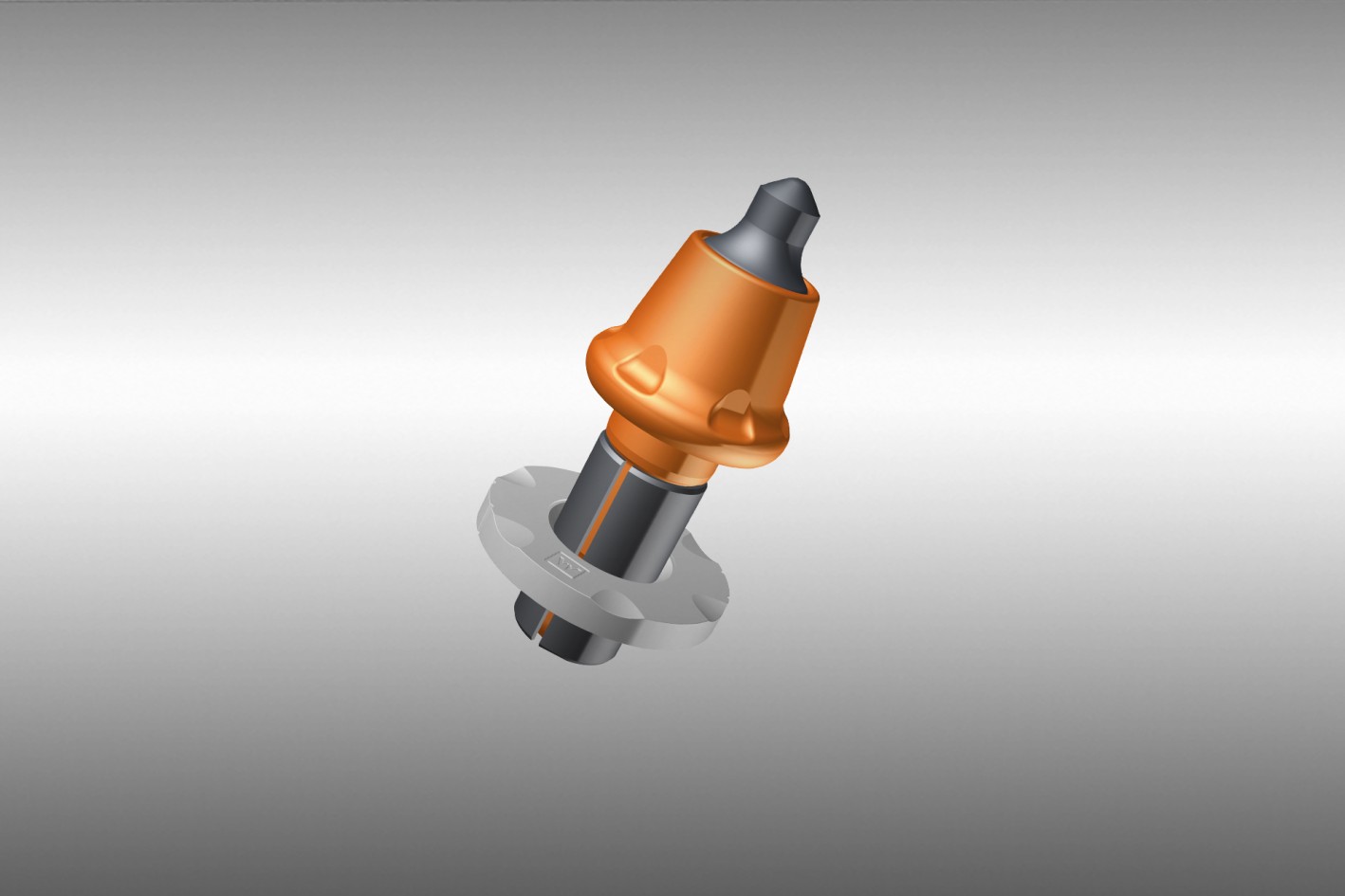

PCD milling tools with a highly wear-resistant tool tip made of polycrystalline diamond are the ideal choice for surface course rehabilitation and (micro) fine milling.

All-rounder for cold milling

The GENERATION A² picks excel due to unique product features, which, above all, reduce operating costs significantly. Thanks to the newly developed wear plate with a special groove profile, centring is improved and rotation performance demonstrably optimised. This ensures that the carbide retains its high cutting performance and guarantees optimum carbide utilisation. The groove profile also reduces lengthwise wear in the pick toolholder and increases service life by up to 25 %.

Carbide is the most economical solution as a cutting material for inhomogeneous materials being milled with abrupt peak loads to be expected. The all-round GENERATION A² carbide picks thus provide the optimum solution for every application, no matter whether you need to handle hard or soft asphalt or are milling concrete.

IMPRESSIVE:

Specialist in surface course rehabilitation and (micro) fine milling

PCD milling tools are perfectly suitable for surface course rehabilitations and (micro) fine milling applications due to their tool geometry and materials. They feature a highly wear-resistant tool tip made of polycrystalline diamond (PCD) with an extremely long service life. The very slight lengthwise wear ensures optimum evenness over the milled surface and consistently high machine feed.

Depending on their application, PCD milling tools are a useful addition to the existing pick range featuring conventional carbide tips.

PCD milling tools: Polycrystalline diamond (PCD) is the optimal solution as a cutting material for homogeneous asphalt packages, particularly where no abrupt peak loads are expected. PCD milling tools are particularly ideal as an economical alternative for surface course rehabilitations up to 8 cm and for (micro) fine milling applications.

IMPRESSIVE: