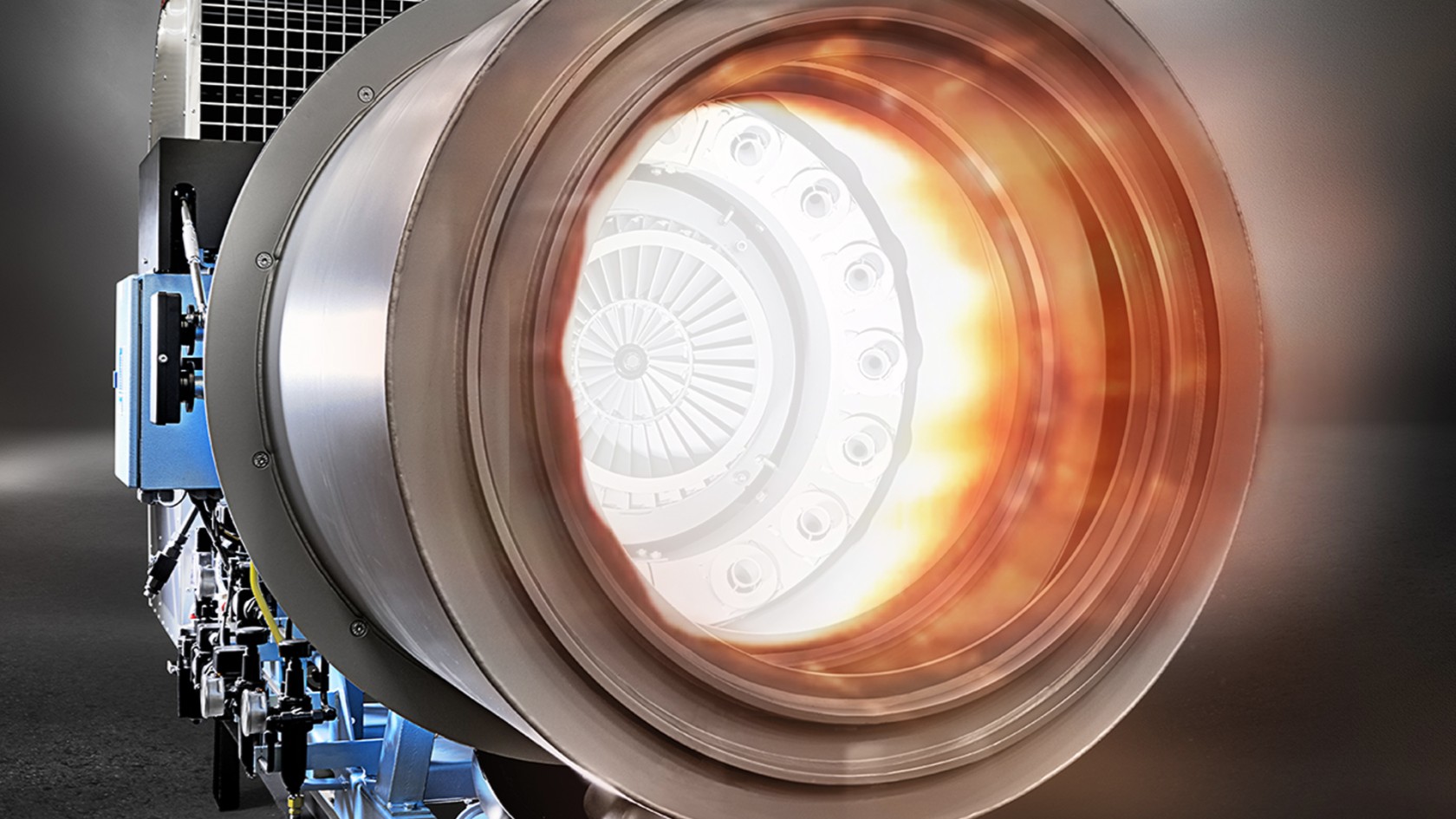

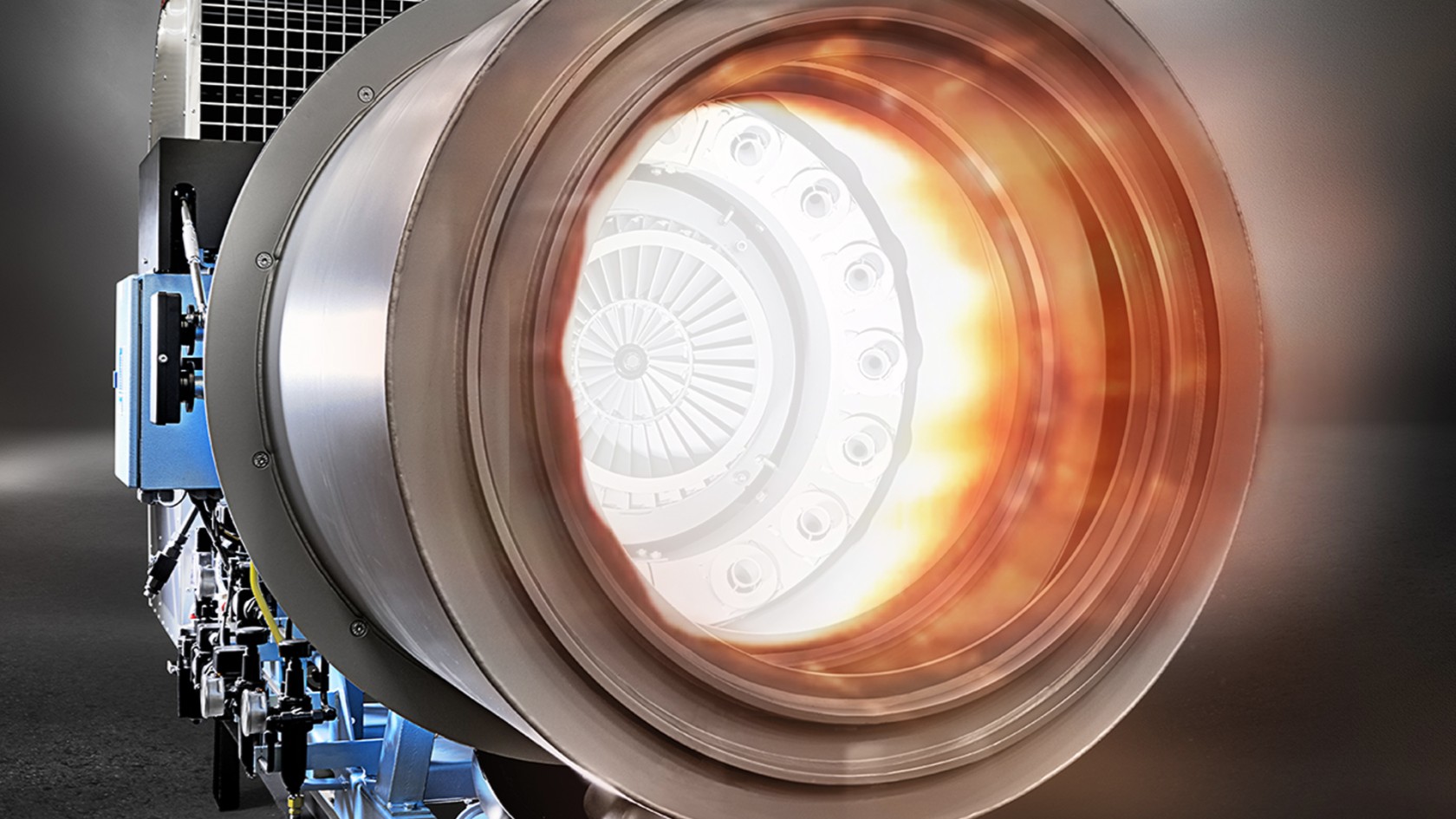

EVO JET

The burner is one of the most important components of any asphalt mixing plant. It is the prerequisite for optimum results for drying mineral and therefore for the quality of the mixture.

For the design and manufacturing of the famous EVO JET burners, BENNINGHOVEN – the youngest subsidiary of the WIRTGEN GROUP – uses expertise which is unrivalled worldwide. One important reason for this: Founded in 1909, the company initially manufactured burners for different areas of application and is the inventor of the fully automatic ignition with photocell flame monitoring. This innovation was the deciding factor for the start into manufacturing of asphalt mixing plants in 1978. Today, the company is still the only manufacturer of asphalt mixing plants with in-house burner production.

Peter Koltes, Head of Combustion Technology BENNINGHOVEN

The EVO JET burners have gained a legendary reputation and still provide a crucial contribution to the success of BENNINGHOVEN today. "They feature maximum reliability and can be operated with up to four different fuels such as heating oil (extra light, medium and heavy), liquid gas, natural gas, solids (coal dust) or a combination of several fuels – they are the only burners to do this," Peter Koltes, Head of Combustion Technology at BENNINGHOVEN, explains the benefits.

Public Relations

Reinhard-Wirtgen-Straße 2

53578 Windhagen

Germany