Concrete paving inset

The following sequence of operations is typical of inset paving: First of all, trucks unload the concrete in front of the paver.

The concrete paver then spreads the concrete over the full paving width with its auger or spreading plough and forms the concrete profile for the roadway with the slipform mould. HF vibrators inside the slipform vibrate at high frequency, expelling air from the concrete and hence compacting it.

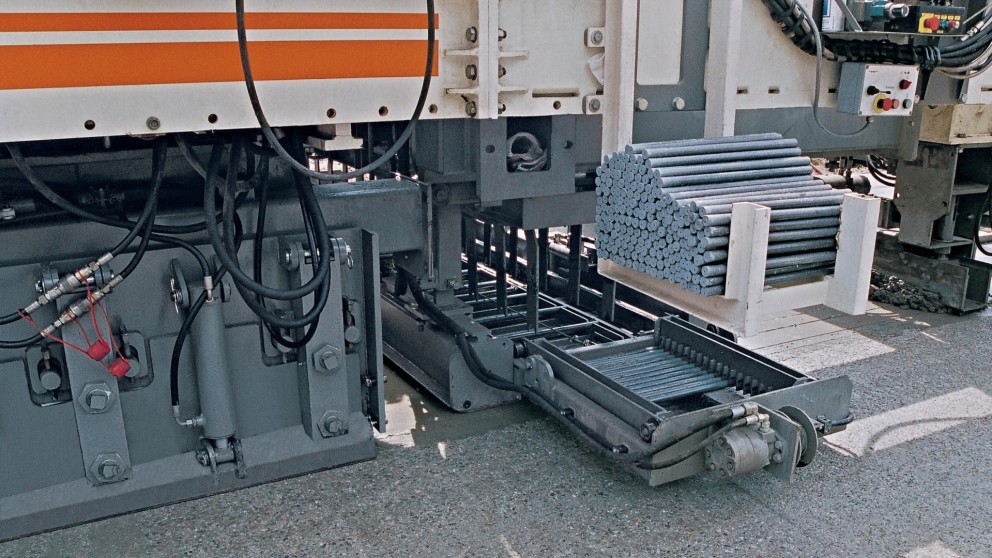

The slipform paver keeps moving all the time during the paving operation, its working speed ranging from 1 to 2 m per minute. At the same time, the paver can also insert dowel bars or tie bars in the fresh concrete. These bars reinforce the concrete. Slots are subsequently cut into the concrete pavement above the reinforcements. These slots ensure that the cracks which are invariably produced as a result of stresses and temperature fluctuations are diverted into the concrete pavement in a controlled manner.

Automatically inserted dowel bars transfer loads from one concrete slab to another.

The roadway is levelled by finishing beams and super-smoothers. An entrained piece of sackcloth often ensures a non-skid surface texture. A curing unit is normally used to apply a dispersion to the fresh concrete so that the concrete cures uniformly.

When paving asphalt, the road paver always sets the pace. After all, its performance determines, for instance, how many asphalt mixing plants are commissioned, how many trucks are needed to transport the mix to the construction site and how many rollers are needed for final compaction.

Click here for more information on asphalt paving with road pavers from VÖGELE.

View asphalt paving