Road Construction History

In 2021, the Wirtgen Group will celebrate 60 years of Wirtgen. Time to take a look back and a look ahead. Vögele, Hamm, Kleemann, and Benninghoven have also played a leading role in shaping the industry’s technologies. Together, the Wirtgen Group stands for more than 660 years of experience – and has always set the trends throughout the history of road construction.

The Wirtgen Group’s brand headquarters in Germany are among the most cutting-edge production facilities in the industry. Lean production processes, clear workflows, and ergonomic workstations come together to ensure that these locations deliver premium technologies. The basis for this success is a continuous development process that stretches far back into the past.

Wirtgen’s success story is well known in the industry. Here’s the short version: In 1961, Reinhard Wirtgen launched his career as a trucking contractor for road construction companies. A few years later, he built his first two concrete shattering machines in an empty chicken coop. That was in 1965 – and even then, the young founder demonstrated vision and courage beyond his years. He recognized the advantages of his design over the crawler excavators common at the time. And sensed the opportunity to gain a foothold as a service provider in road construction. Innovations in road rehabilitation are the hallmark of Wirtgen’s path, and this is how the company evolved into a manufacturer of road construction machinery – a vision became reality. Today, the Wirtgen Group encompasses five brand headquarters in Germany, production facilities in Brazil, China, and India, and its own sales and service companies. And is proud to be a strong part of John Deere.

WIRTGEN TodayVögele’s beginnings reach far back into the past. In 1836, Joseph Vögele founded a small blacksmith’s shop in Mannheim, near the Heidelberg Gate. The timing was ideal, because just one year earlier, the first German train had completed its journey from Nuremberg to Fürth. Joseph Vögele recognized the opportunities that were opening up as a result of the growing rail network. Vögele’s product range soon included everything from railroad switches and turntables to transfer tables and shunting systems. Starting in 1890, the company began receiving its first major orders from the Prussian state railways, including for the construction of Frankfurt’s main train station. When Heinrich Vögele, the son of the company founder, took over management of the company with his children Joseph and Wilhelm at the beginning of the 20th century, Vögele was one of the most prominent railroad switch manufacturers in the world. In the 1920s, Vögele discovered road construction as a new area of business. The use of engines was increasing, bringing more and more cars and trucks onto the roads. Construction companies were covering the roads with tar or concrete pavements. Since plans for two-lane highways were already underway, contractors and manufacturers of construction machinery expected to receive many large orders. After 90 years as a manufacturer of railroad equipment, Vögele entered a new era as a manufacturer of road construction machinery.

VÖGELE TodayThe gunsmiths Franz Hamm and Anton Hamm founded the Maschinenfabrik Gebrüder Hamm (“Hamm Brothers Machine Shop”) in Tirschenreuth, Germany, in 1878. In their workshop on Schmellerstrasse, they initially produced agricultural equipment such as mobile threshing machines. The company also participated in major construction projects, such as the construction of the water pipeline in Tirschenreuth in 1900. They soon ran out of space, so in 1908 the Hamm brothers – who at this time already had 21 employees – expanded their workshop for the first time. In addition to agricultural machinery, they also manufactured portable engines. As industrialization advanced at the turn of the century, the road network grew. Construction companies used steamrollers to compact road surfaces. Hamm also saw road construction as a promising new business segment that had already been developed in England, but was still in its infancy in Germany. When the Royal Bavarian District Office decided to purchase a roller for road construction in 1911, Hamm saw its big chance. After 30 years as a manufacturer of agricultural machinery, the Hamm brothers entered the road construction business.

HAMM TodayIn 1857, Ferdinand Kleemann founded a file cutting workshop in Obertürkheim, near Stuttgart, Germany. He expanded his product range early on, initially to include forage harvesters and other agricultural equipment, and later also eccentrics. In 1878, his descendants purchased a plot of land on Augsburger Strasse and built a new workshop and foundry there. Heinrich, one of Ferdinand’s four sons, established a business relationship with a manufacturer from Göppingen-Faurndau by marrying his daughter, and soon took over management of the company Hildenbrand & Söhne. Kleemann discovered rock processing in 1902. After Heinrich Kleemann’s death, Friedrich Kleemann and Wilhelm Kleemann merged the Hildenbrand company with Kleemann’s company to form the “Kleemanns Vereinigte Fabriken Obertürkheim und Faurndau” (“Kleemann’s United Factories in Obertürkheim and Faurndau”). In the same year, they started building stationary stone processing plants, thereby taking a first step into the market for processing technology. This area, however, remained only a secondary line of business for the company for many years. Up until World War I, Kleemann not only manufactured stone crushers and ball mills, but also, among other things, wine press machines, elevators, and sorting drums. After World War II, production at Kleemann was slow to get going again. It wasn’t until 1952 that the company was able to build on its old successes. Its main products remained machines for stationary processing systems and hydraulic lifting platforms. After the death of Hans Kleemann, his sons Fritz and Johannes Kleemann took over management of the company in 1966. Under their leadership, Kleemann now also produced hydraulic elevators and special hydraulic systems for town halls, gymnasiums, and swimming pools. In 1976, the company introduced an innovation in processing technology – Kleemann built the first wheeled mobile crusher for a customer in the United Arab Emirates, which was based on the wheeled mobile jaw crusher it manufactured back in the 1950s. Customers in the Middle East remained the main purchasers of the mobile plants for many years; in Germany, Kleemann gradually evolved into a specialist for stationary processing plants.

KLEEMANN TodayIn 1909, Otto Benninghoven started a company in Hilden, Germany, that manufactured gears and special machines. The company entered the field of industrial combustion technology a few decades later, in the 1950s. In the following decade, the asphalt industry became increasingly important area of business for the company. In 1970, the company moved into a new, state-of-the-art production facility in Mülheim, Germany, which simultaneously became its new headquarters. A newly built electrical and final assembly hall has been in use there since 2007. A second facility was operated in nearby Wittlich, where mainly steel construction and the assembly of screens and drying drums took place. In 2016, Benninghoven held the ground-breaking ceremony for the construction of its future brand headquarters in Wittlich-Wengerohr. Today the company conducts all of its manufacturing processes at this location.

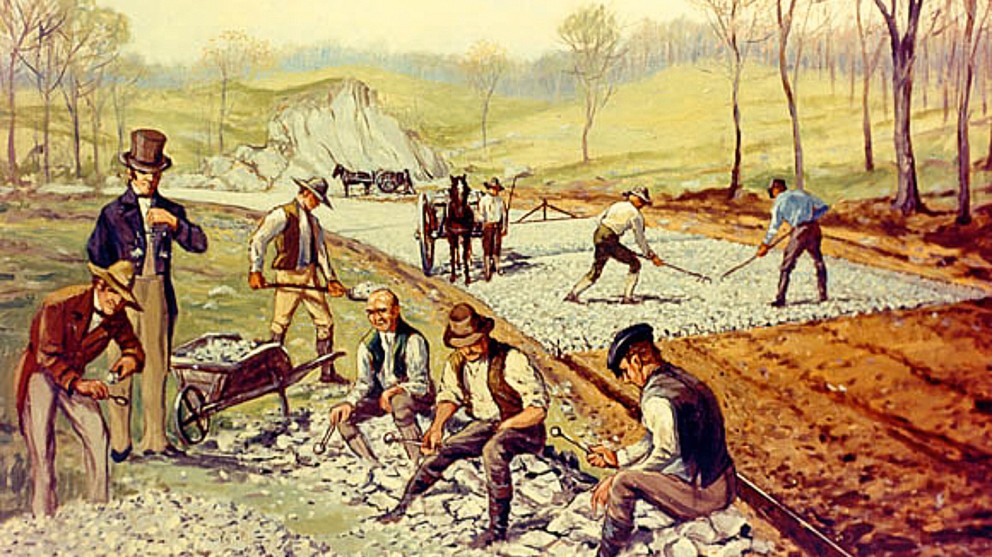

BENNINGHOVEN TodayAt the beginning of the 18th century, the old road construction techniques used by the Romans were revived and specifically advanced. Until then, roads were usually entirely made of dirt, which in rainy weather then turned into muddy, impassable thoroughfares. Gravel and cobblestone roads improved the situation and therefore came into fashion and were systematically built. Thomas Telford and John Loudon McAdam laid the foundations for modern road construction during this period. Their insights into a tiered layer structure (known as macadam construction) and effective drainage of roads continue to apply today. In order to transport people and goods as quickly as possible, the number of superregional road connections increased steadily in addition to roads within city limits. Paved highways created a network of long-distance roads stretching right across Europe, and they only lost their importance with the advent of railroad construction.

1822: The first road built using the macadam method in the United States linked Hagerstown and Boonsboro, Maryland.

The emergence of motorized vehicles brought about a fundamental change in road construction. This new means of transportation required further reinforcement of the road structure and a completely new way of thinking about how roads should be laid out. The roads built up to that point were too uneven and curvy – far too unsafe for faster vehicle traffic. Another issue was the widespread problem of dust generated by vehicles driving over unbound surface layers. Consequently, surface layers were bound with tar, bitumen, or cement. This was the birth of modern asphalt and concrete road construction as it is still in use today.

Collectively, the companies of the Wirtgen Group bring their full strength to bear wherever our customers need it and as a unit that benefits from its diversification. Our success is based on the trust placed in our employees and the satisfaction of our customers. In order to complete a job on time, Reinhard Wirtgen was never above working on the machines himself late into the night. Similarly, today we still strive to offer our customers products of the highest quality, the most advanced technologies, and the most comprehensive service. This aspiration is reflected in our value proposition “Close to our customers.” And this tradition lives on under John Deere as well.

History of the Wirtgen Group