Wirtgen W 100 CFi: A special job for the compact milling machine, extending the broadband network

In Austria, a Wirtgen W 100 CFi compact milling machine with deep milling unit is being used for trenching prior to the laying of broadband cables – just before it sets to work milling off entire pavements.

The spread of fiber-optic cables is advancing rapidly across the world, and the Upper Austrian district of Schärding, not far from the German border, is no exception. Here, too, communities are being given broadband internet access. Engelhartszell is the second community to benefit from this technology of the future. And the contractor, Hemmelmair Frästechnik GmbH from Linz, is also making use of cutting-edge technology, in this case made from steel and carbide. For local roadworks, the milling service provider is using the W 100 CFi, a model from the latest generation of compact milling machines featuring a deep milling unit that WIRTGEN have developed especially for this application.

For the trenching job in Upper Austria, Hemmelmair Frästechnik GmbH opted to use the compact milling machine W 100 CFi from Wirtgen. The modern trenching method for laying pipes and cables cuts costs while speeding up the advance of fiber-optic cables.

“We have 15 WIRTGEN cold milling machines in operation. In the course of our long-standing collaboration, we have come to prize the solutions expertise of the company, and this prompted us to turn to the WIRTGEN GROUP in Austria in this case, too,” explains Manfred Grössing, Managing Director of Hemmelmair. Once the requirements had been discussed with WIRTGEN‘s product management team, the design department at the brand headquarters in Germany was given the development order. “We wanted our customer to be able to use the milling machine flexibly, i.e. be able to switch back to conventional repair jobs as quickly as possible,” says Manfred Stiegler, Customer Service Manager at the WIRTGEN GROUP‘s sales and service company in Austria.

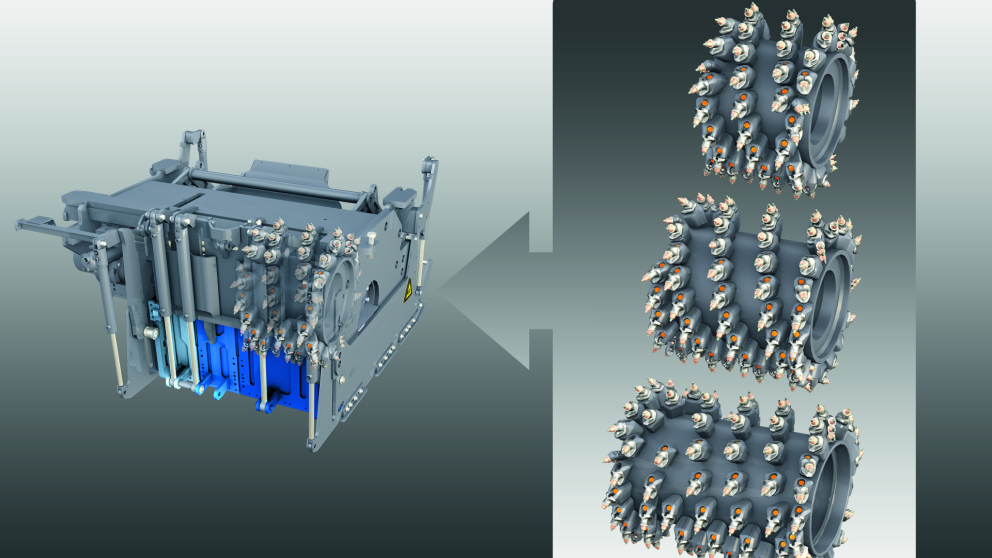

With a powerful cold milling machine and a customized deep milling unit fitted with a narrow cutting wheel, Wirtgen offer a cost-effective solution for the laying of broadband cables.

The W 100 CFi was the ideal candidate for the job in Upper Austria. One of the new generation of WIRTGEN compact milling machines, it integrates many innovative added and automated functions that give highly effective support to users when operating the machine and optimize work processes. WIRTGEN developed a special solution for the trenching method. A housing containing a narrow cutting wheel fitted with standard W6 picks is mounted behind the folded-in crawler track on the right. With a very large cutting diameter of 1,620mm, it can mill channels up to 600mm deep and 300mm wide. The rotary milling motion conveys the milled material upwards, where it is discharged via a baffle plate and chute.

Once the empty pipes have been laid, the adjacent surface course is usually milled and the channel is overlaid with a new overlapping layer of asphalt.

The deep milling unit is controlled from the traditional control panel of the W 100 CFi. “This means that the machine operator can operate his milling machine in the usual way,“ explains Andreas Salz, responsible for design and development of cutting technology.

Manfred Grössing, Managing Director of Hemmelmair, was immediately won over by the WIRTGEN trenching solution: “The easy assembly and dismantling of the deep milling unit and the straightforward transport of the W 100 CFi allows us to use the milling machine flexibly and thus optimally.“ That was also the case with the job in Upper Austria: shortly after the trenching job, the W 100 CFi compact milling machine was being used to repair a country road. Here, too, the W 100 CFi hit the spot with its cost effectiveness, in this case mainly thanks to the Flexible Cutter System.

With the Flexible Cutter System, Wirtgen provides an optimum solution for a maximum range of use.

The WIRTGEN Flexible Cutter System, or FCS for short, delivers the optimum solution for high machine capacity utilization: milling drums with a variety of tool spacings or working widths can be replaced in a short space of time. It takes only 0.5 to 1.5 hours to replace the drum, depending on the machine – converting the cold milling machine from a standard to a fine milling machine, for instance. Removing ruts from a country road, preparing a carriageway for a thin overlay using a fine milling drum or removing coatings on asphalt or concrete surfaces with a micro fine milling drum – all of these tasks can be handled with one and the same cold milling machine. The range of FCS milling drums is large, opening up a vast array of applications for cold milling machines.