Milling layers separately, recycling economically

During rehabilitation work near Tokyo, a W 210 large milling machine removed the surface and binder courses on the Jōban Expressway in individual layers. This makes it easier to separate the milled material according to type of mix and reuse it more purposefully. Wirtgen milling technology makes the entire operation particularly economical.

The city of Mito is located around 140km north-east of Tokyo and is home to Kairaku-en, a shining example of a perfect landscape garden and one of the most famous of its kind in Japan. Professional maintenance of the garden is essential – and this is also true of roads, which need to be rehabilitated from time to time. For the selective removal of the pavement on the Jōban Expressway, the contractor Unite Co., Ltd. elected to use the latest milling technology from Wirtgen. In action: the powerful 2-metre front loading W 210 cold milling machine.

Precision right down the line: Wirtgen cold milling machines not only create an even base for new asphalt pavements that is true to cross-section line and level. They also contribute to the highly economical recycling of milled material in asphalt mixing plants.

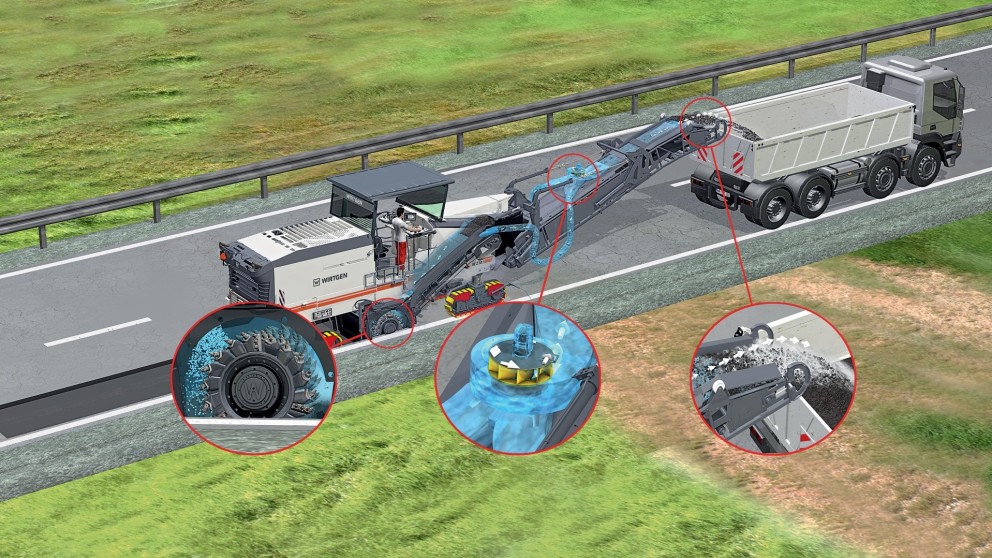

While traffic continued to flow on one lane, the powerful 500kW large milling machine set to work removing the damaged sections. “Our machine is equipped with the Vacuum Cutting System (VCS),” explains Site Manager Mr Koji Yamada. Five years ago, the VCS vacuum cutting system developed by WIRTGEN was included in the New Technology Information System (NETIS) of the Japanese Ministry of Land, Infrastructure, Traffic and Tourism.

During the milling process, fine material particles and water vapor are produced in the milling drum aggregate. The Vacuum Cutting System applies negative pressure to suck the particles and water vapor into the milling machine’s short conveyor channel directly at the milling unit, which is additionally sealed. A suction hood located above the conveyor channel draws the particles into two hoses that lead directly to the long conveyor of the loading system.

To repair cracks in the road pavement, the large milling machine in Mito was equipped with a standard milling drum. After removal of the 10cm-thick surface course, the W 210 cold milling machine milled the binder course to a depth of 15cm in a second pass. Because the different types of mix were separated, it was possible to return both layers to the material cycle for reuse in line with their technical suitability and qualitative characteristics. The selective reclaiming of the material alone delivers clear ecological and economic benefits. When intelligent milling technology is factored in, Wirtgen cold milling machines not only optimize the overall rehabilitation process, but also the cost-effective reuse of the RAP in the asphalt mixing plant.

Load-dependent water sprinkling plays a key role here. The water required for cooling the cutting tools is regulated in accordance with the engine load and milling speed. As the water system is automatically switched on when the milling drum is lowered into working position and automatically switched off when the milling work is stopped, water consumption can be cut considerably. Specifically, up to 20% of the water can be saved.

As a result, the service life of the cutting tools is extended, the cold milling machine requires less frequent refills and the downtimes are shorter. In addition – and this is decisive for materials processing – the residual moisture of the milled material is only 3–4% per ton. If Wirtgen milling technology is not employed, the residual moisture is generally 5%.

Selective milling: With the help of modern machine technology, the surface, binder and base courses can be removed separately and also returned to the material cycle separately. This increases the sustainability of RAP recycling.

When producing new asphalt, a simple equation applies to the drying process in the asphalt mixing plant: 1% drier source material saves 1 liter of heating oil in the production of 1t of asphalt. On top of this comes a reduction in CO2 emissions due to the lower energy requirements. When processing the milled material on the Jōban Expressway, a total of some 400 liters of heating oil were saved – and in just two hours, as this was how fast Unite Co., Ltd. selectively and precisely removed the surface and binder courses with the powerful W 210. Site Manager Mr. Koji Yamada says: “The quality of the milled surface is flawless thanks to the Level Pro levelling system – it’s the perfect base for paving and compacting the new asphalt.”

The up to 20% lower water consumption with Wirtgen milling machines increases energy efficiency, as the following applies: −1% water in the source material = −1 liter heating oil per ton of asphalt during further processing into recycled mix, e.g. in Benninghoven asphalt mixing plants.

For the Jōban Expressway site, this means:

Result: The potential quantity of heating oil that can be saved in the mixing plant as a result of using the Wirtgen cold milling machine is around 500 liters.

“The WIRTGEN Vacuum Cutting System is a clean solution and ensures the best visibility con-ditions.” Kazunari Watanabe, Milling Machine Operator Unite Co., Ltd.