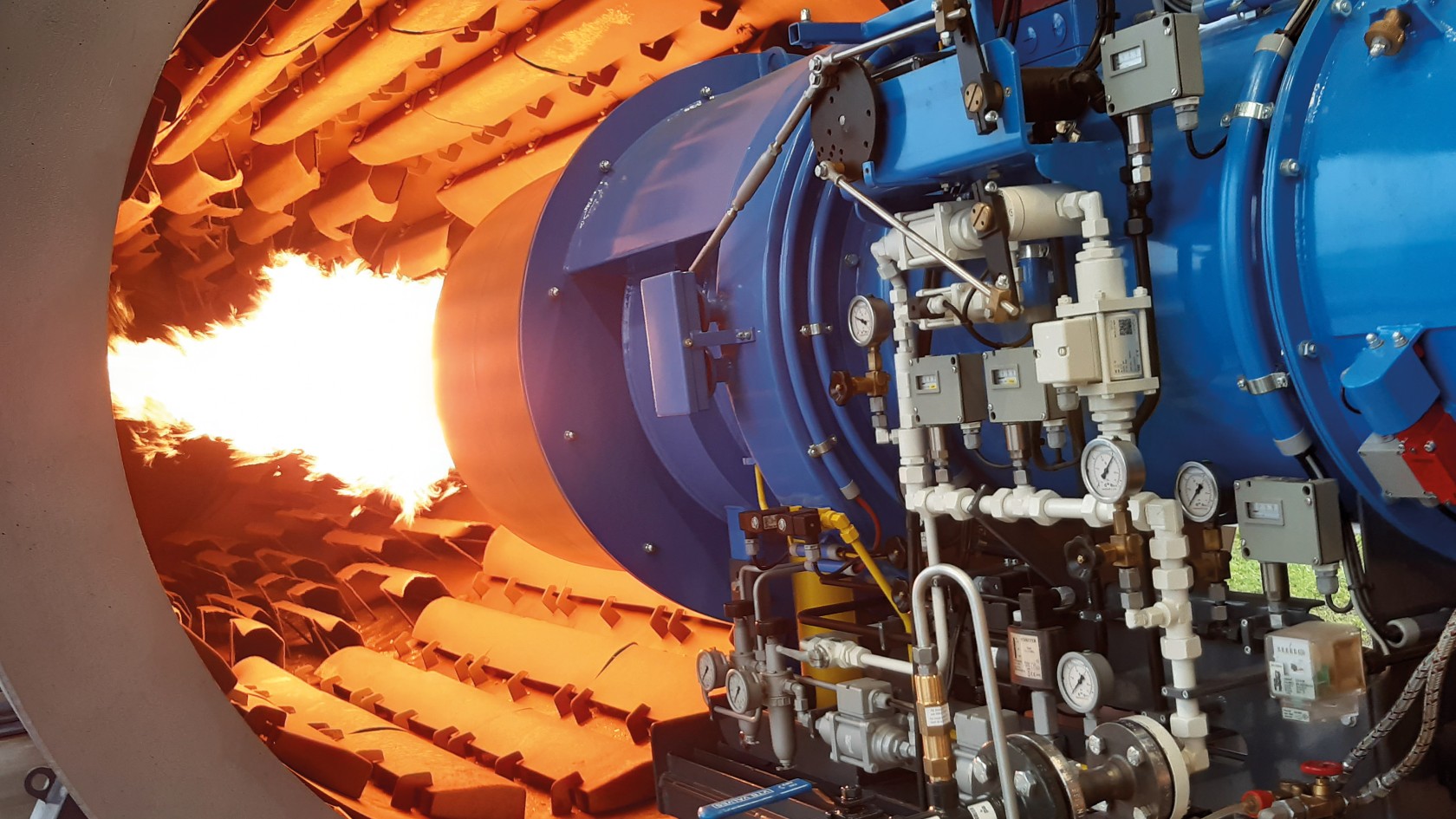

Benninghoven burners EVO JET

BENNINGHOVEN is a world market leader in burners for asphalt mixing plants and a manufacturer of multi-fuel burners with up to 4 fuels. The complete know-how and wealth of experience from over 70 years of burner competence support the development of unique burners with excellent properties.

Continuously rising energy costs and careful use of limited resources require innovative technologies and continuous further development. The burner type EVO JET was developed by the BENNINGHOVEN research team in practical application.

At the same time, the popular and proven user friendliness played an essential role in the development of the burner. The burner has a modular structure and is easily accessible.

To move the burner for maintenance purposes, it is set onto a corresponding chassis. Frequency converter technology allows the burner fan as well as the oil pump to operate in all control ranges, in perfect coordination. This means that only the actually requested consumption is used for drying in all performance ranges. The complete new development of the silencer combines noise reduction with improved combustion efficiency. This is achieved with the new positioning of the air intakes. The higher efficiency is due to the fact that the heat radiated by the face side of the drum is captured and the pre-heated air is guided to the burner. This means less energy is required for pre-heating the air. This helps to lower fuel costs. The burners from the EVO-JET series were developed for all fuels and have proven successful in practical application. The energy saving range is completed by the fact that BENNINGHOVEN already uses electric motors complying with the IE 2 (or IE 3) standard, which will become mandatory in the future.

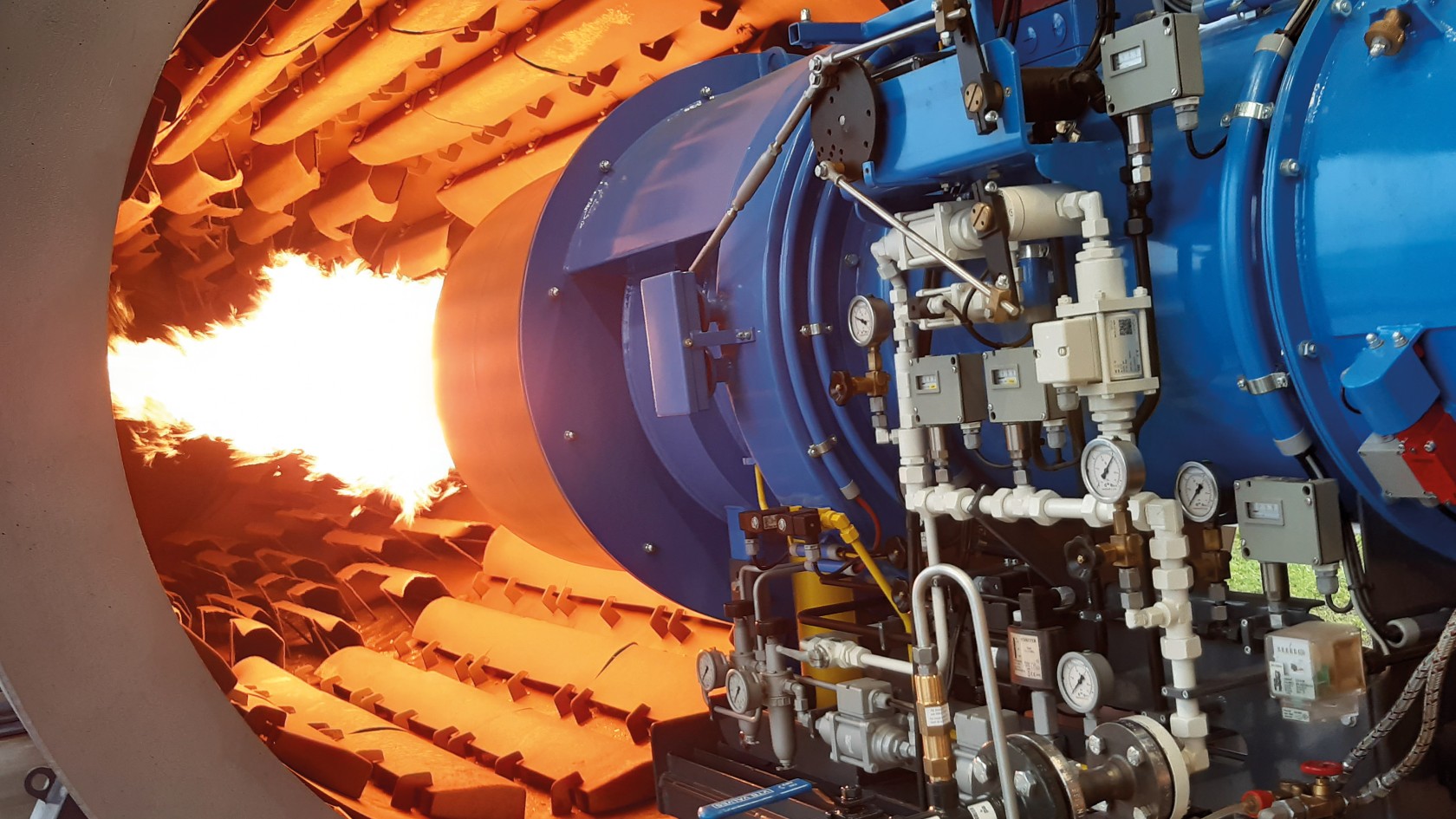

100 % green hydrogen system for road construction

With the world’s first burner that can be run with 100 % green hydrogen, BENNINGHOVEN offers a pioneering solution for more sustainability in road construction.

Everything from a single source – From the hydrogen source, the Benninghoven scope of delivery comprises the feed systems including the pressure control section, multi-fuel burner, hydrogen control section, burner control and plant components adapted to hydrogen operation.

In addition to this, the burner is supplied with a new control system. This coordinated hardware and software solution ensures an efficient process during asphalt production.

New plants as well as existing asphalt mixing plants can be equipped with the burner technologies from Benninghoven. Retrofit solutions can also be used for plants from other manufacturers. This gives any plant owner the opportunity to change to the latest technologies at any time – a key aspect for achieving economical and sustainable asphalt production and securing the future of the site in the long-term.

Download