Renaming wear parts

Our Kleemann Original Parts sparkle with their new designations and a new colour design.

The following section provides you with information on the new naming concept.

With the use of Kleemann-specific designations, we intend to create a consistent, comprehensible and extendable nomenclature.

This will permit fast and simple identification of the parts. Furthermore, future products in the product family can be included easily and in a more standardised manner in the designation system.

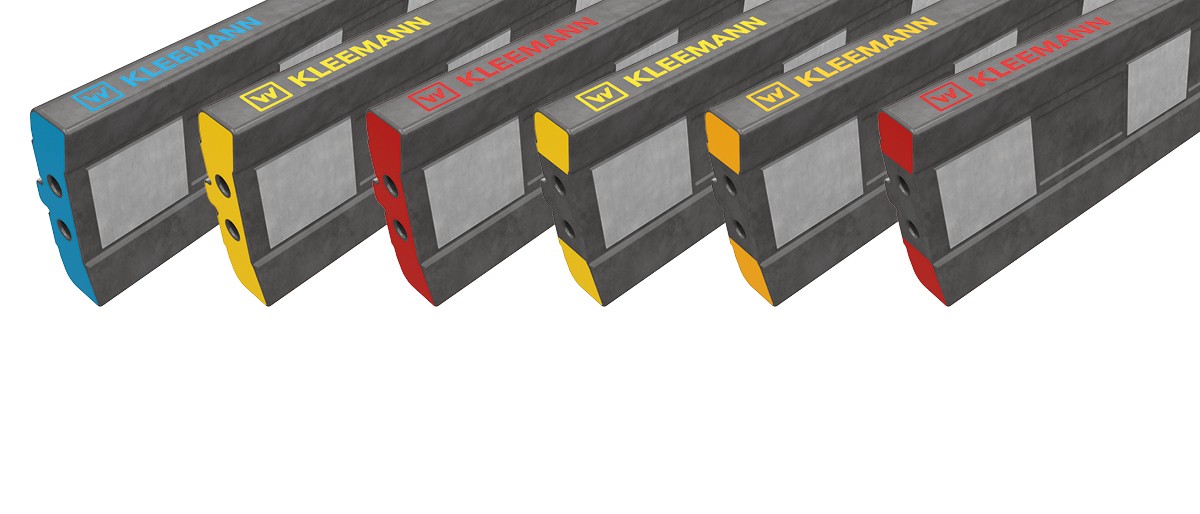

Strength and impact power – representative for our rotor ledges

For simple identification and easy differentiation of the various rotor ledges, each material is identified by a separate colour.

To the Parts SearchOne symbol for the shape of the tool and the crushing process of our crusher jaws

For application in natural stone and recycling, we offer a selection of crusher jaws with different tooth shapes. Depending on the application and component, the manganese share of the material varies – for better differentiation we also work here with different colours.

To the Parts SearchRefers to the shape of the crushing tool of our cone crushers

With our crushing tools, we distinguish between mantles and bowl liners, which cover different application areas and crushing stages. In this case, the variants S-CONE (Standard) and SH-CONE (Short Head) are available. Furthermore, Kleemann offers different crushing tool qualities with varying manganese content depending on the abrasiveness of the crushed material.

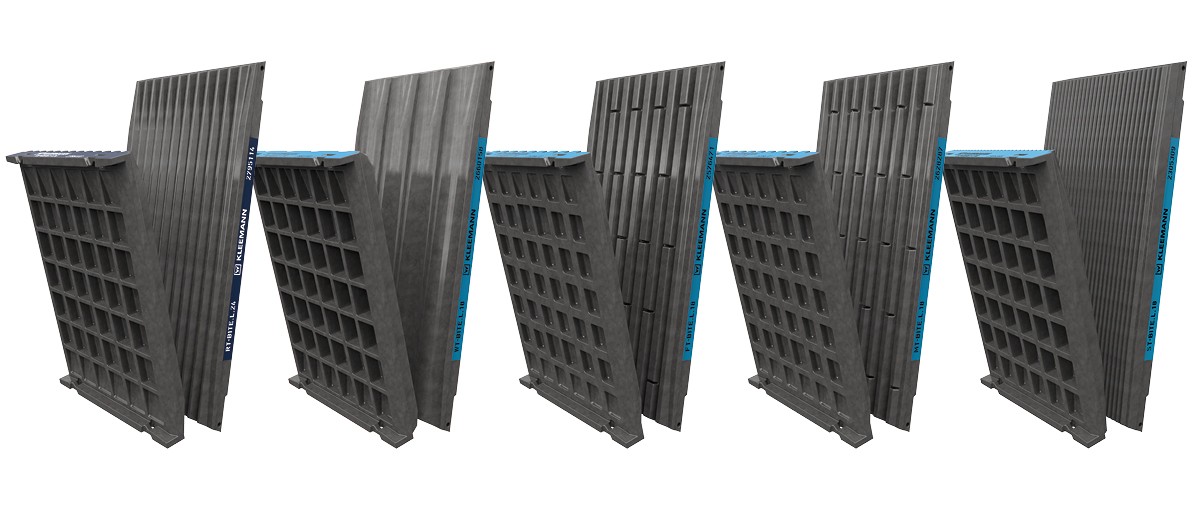

To the Parts SearchKLEEMANN Resistant Steel

To protect the crusher inlet against damage, the complete housing is panelled with extremely wear-resistant KLEEMANN original plates.

The KLEEMANN Resistant Steel (KRS) wear plates are available in 3 qualities, which have different hardnesses and are suitable for different application or wear areas.

To the Parts Search| Name | Specification / hardness |

|---|---|

| KRS.40 | up to 430 HV |

| KRS.50 | up to 530 HV |

| KRS.HW | up to 740 HV 10, approx. 62 HR (hard-face welded) |