The beginnings

Based on a model drawing, the initial drafts of the impact crusher were made which were then digitalized with the help of a CAD program to create standardized coloring for the plant.

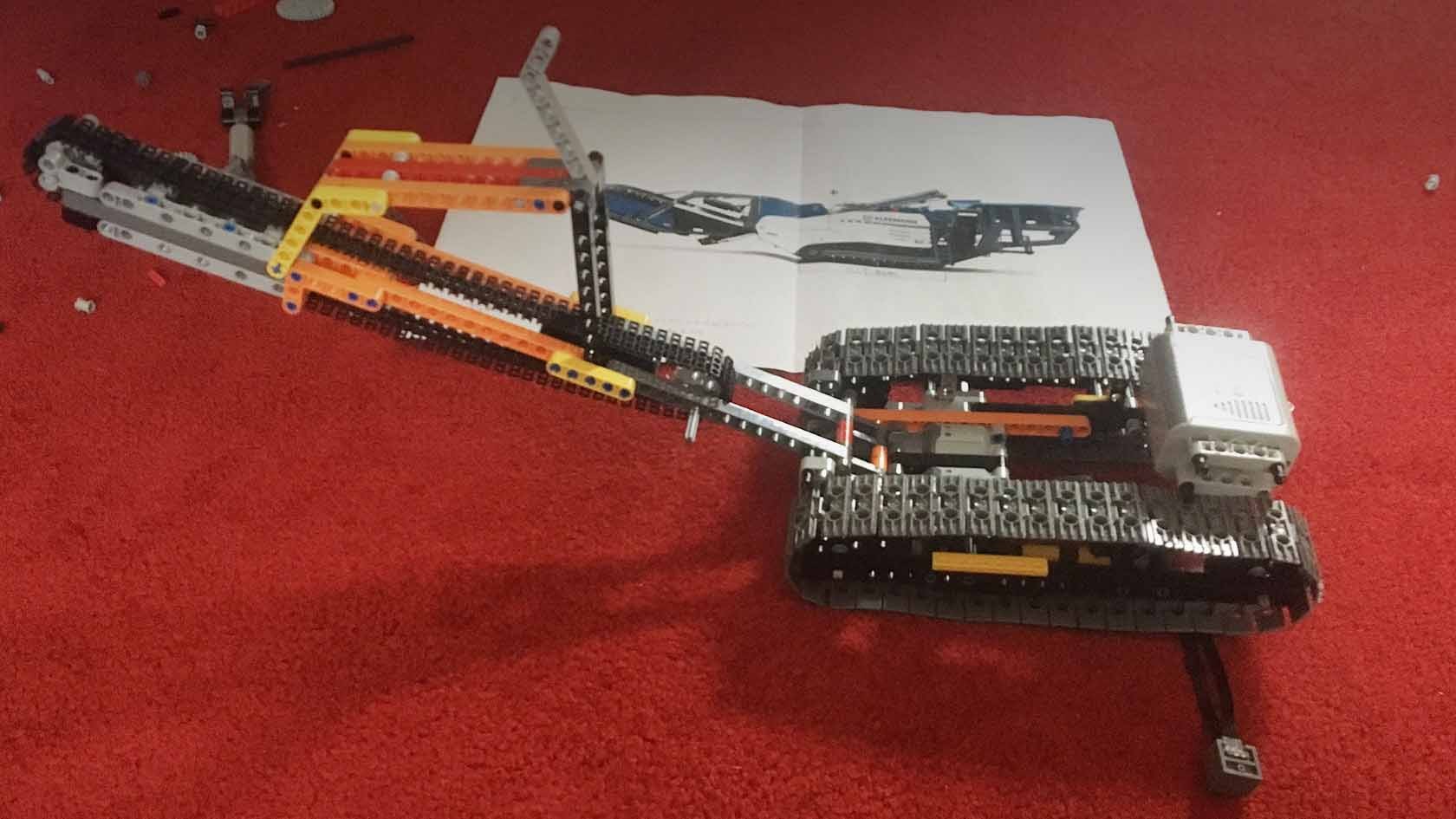

The fascination with Kleemann products was the deciding factor: Tim Schwarz, trainee industrial mechanic, and Tim Grabe, trainee design mechanic, demonstrated great attention to detail when they designed the model of an impact crusher, including its programming.

The trainees fitted a total of 2,700 plastic interlocking building blocks and insertable elements – and it was worth the effort. The impact crusher model not only reflects the original on the outside up to the finest detail but numerous meticulously copied details can also be found inside, including the turning rotor or the hopper that can be folded with a gear wheel. The simulation of the crushing process proves how creative and flexible the two Tims are: Because real stones unfortunately can not be crushed with the model, for demonstration purposes the two young men used chocolate M&Ms!

"The idea of building a model from Kleemann's product portfolio came about after we had used a modular system to create a bucket-wheel excavator."

Tim Schwarz, trainee industrial mechanic, and Tim Grabe, trainee design mechanic in their 4th year as apprentices at Kleemann

Based on a model drawing, the initial drafts of the impact crusher were made which were then digitalized with the help of a CAD program to create standardized coloring for the plant.

The model impact crusher was programmed using the physical computing platform "Arduino".

Arduino makes independent, interactive control of objects possible and is also used, for example, in art colleges to create interactive installations.

The two trainees invested a lot of time in their project. The two trainees met for weeks on end in the Kleemann training workshop to puzzle over their design project. Obviously a great deal of patience was required.

However, the effort was worthwhile. The model stands, functions and now only needs the final touch: Tim Schwarz and Tim Grabe plan to create the model paneling by means of 3D printing so that the exterior also corresponds fully to a Kleemann impact crusher.

Congratulations on your tremendous work!