Extensions with SPECTIVE CONNECT

Even more operator-friendly thanks to new functions and now also available for the mobile jaw crusher MOBICAT MC 120(i) PRO and the cone crusher MOBICONE MCO 110(i) PRO

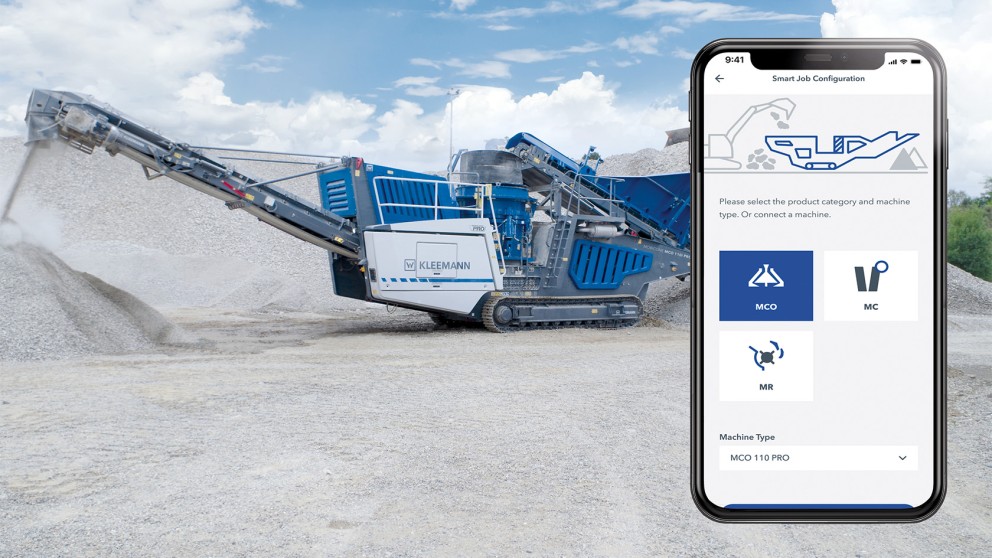

The intuitive operating concept SPECTIVE includes various components that are ideally tuned to one another and accompany the machine operator during the entire working day. The digital extension SPECTIVE CONNECT is now also available for the mobile jaw crusher MOBICAT MC 120(i) PRO and the cone crusher MOBICONE MCO 110(i) PRO. All relevant process information and reporting are now displayed on your smartphone without the operator having to leave the feeding device.

New: The Smart Job Configurator

With the new configuration tool Smart Job Configurator, the operator is supported in the selection of the correct machine setting. For this purpose, the operator first enters the data for his planned application in the SPECTIVE CONNECT App, which then automatically calculates the ideal machine settings. The operator then transfers this data to the machine via the SPECTIVE touch panel.

By the way: Independently of SPECTIVE CONNECT, the rapid entry of the machine settings can also be used by an accomplished operator as a quick-start menu. Important settings can thus be made conveniently via a guided menu.

Selecting, recognizing and tracking crushing tools

Smart Job Configurator makes a typical workday easier: The new configuration tool supports the operator not only in the selection of the best possible crushing tools as well as the recognition of the tools, but also in the tracking of their service life. This significantly simplifies the typical workday.

The Smart Job Configurator in SPECTIVE CONNECTsupports the operator in the selection of the correct machine settings.

New: Production output becomes visible

In SPECTIVE CONNECT, all installed optional belt scales can now also be displayed. A convenient overview of the current production output is therefore possible via the dashboard. The data is recorded in the reporting and allows conclusions to be drawn about the output and utilization of the plant.