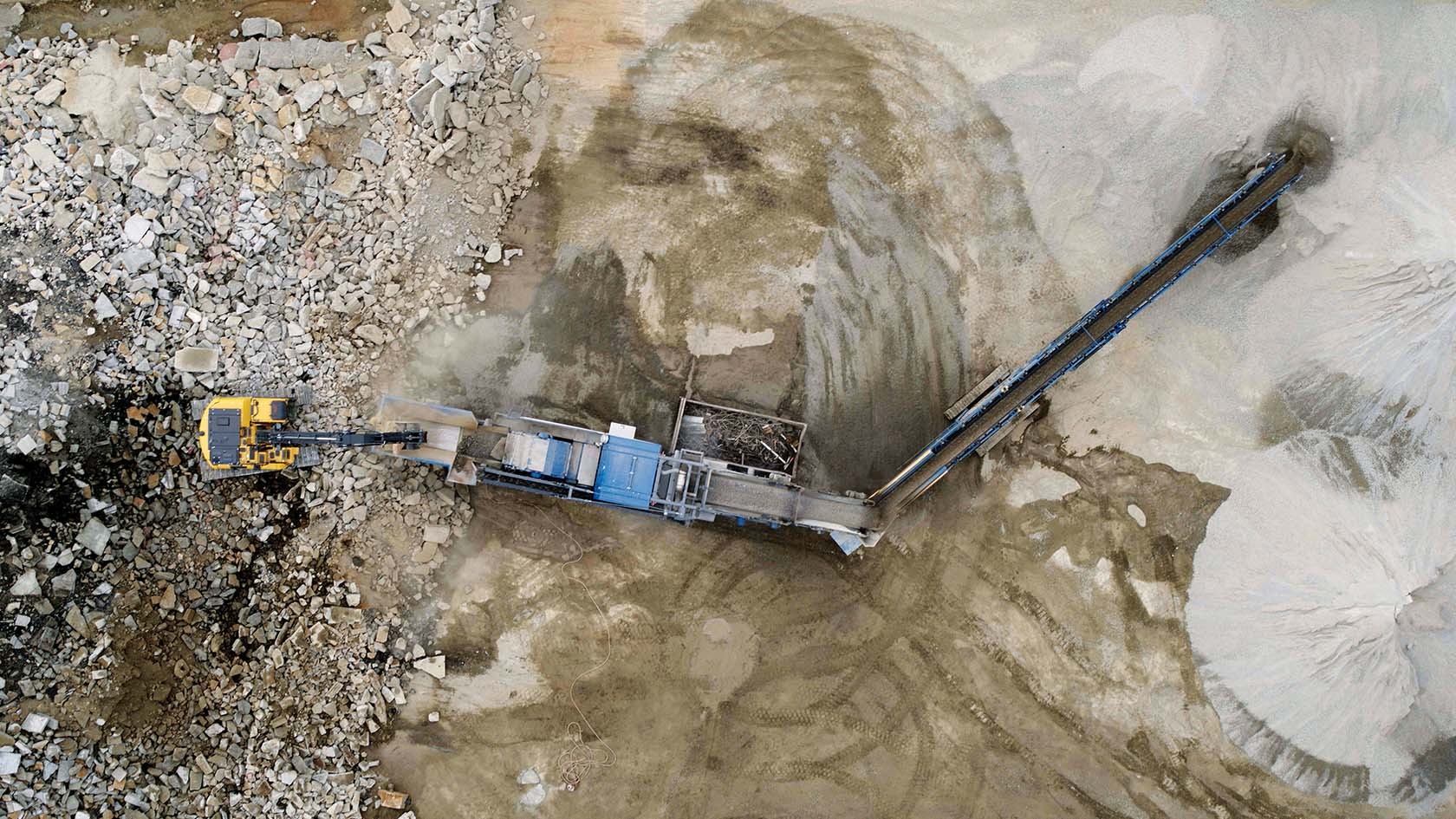

Impact crusher MR 130 Zi EVO2 – powerful and flexible

This powerful impact crusher guarantees first-class product quality and achieves impressive throughputs. The machine is easy to transport and impresses with short setup times during commissioning and maintenance, as well as high machine availability. The flexibility of the Kleemann machine enables the operation to crush wherever necessary, allowing Ramco to crush the material directly where to customer require.

“Working with the Kleemann is fantastic. A lot of great features on it and we really love it. This is really good for us because we could go between our facilities and crush and even go crush for some of our customers. They have a pile that they need to have crushed up and it is too much to bring into one of our yards, so we will go over there to crush it on site for them”, says Dallas Jones, Vice President of Operations at Ramco.