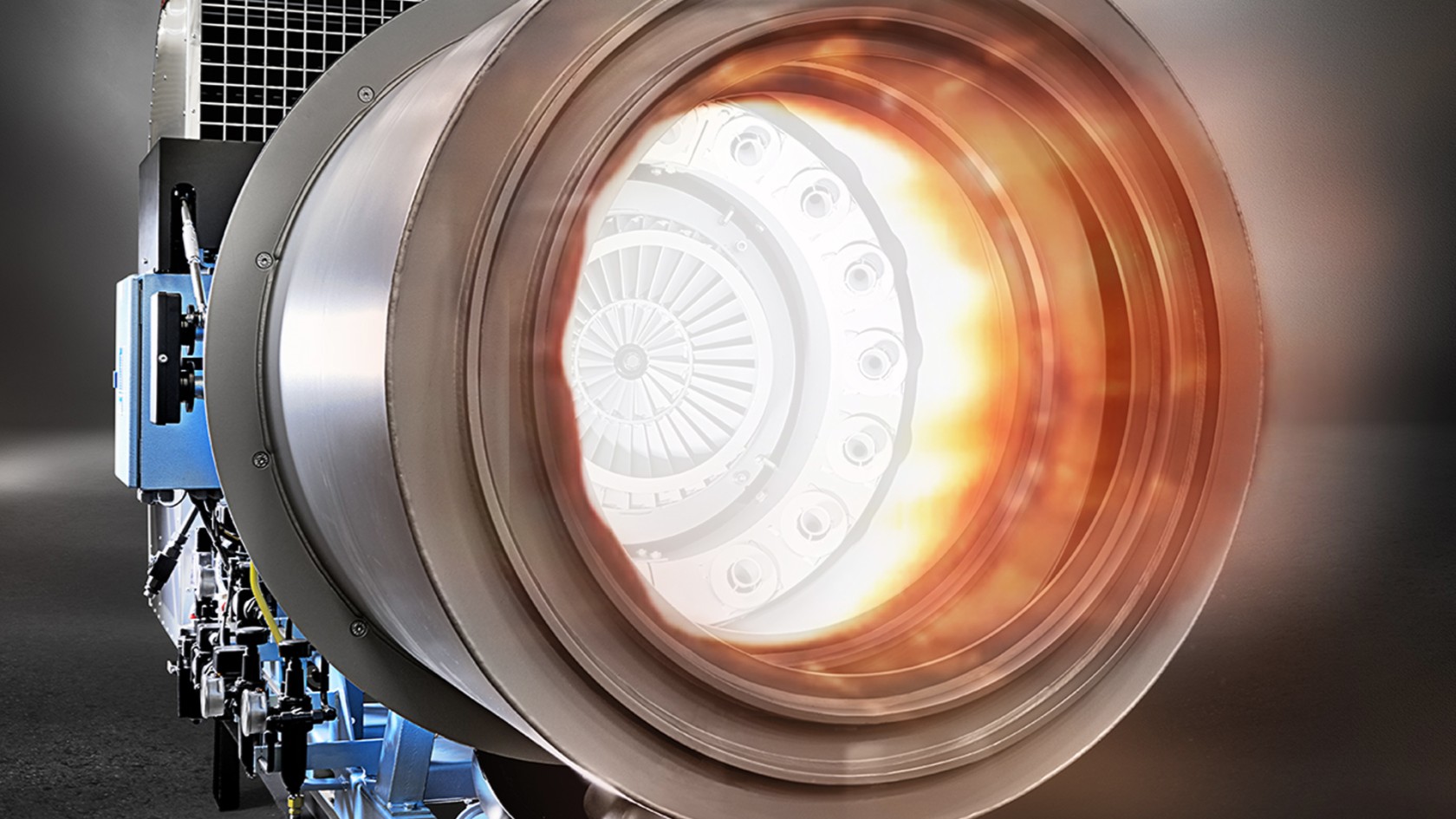

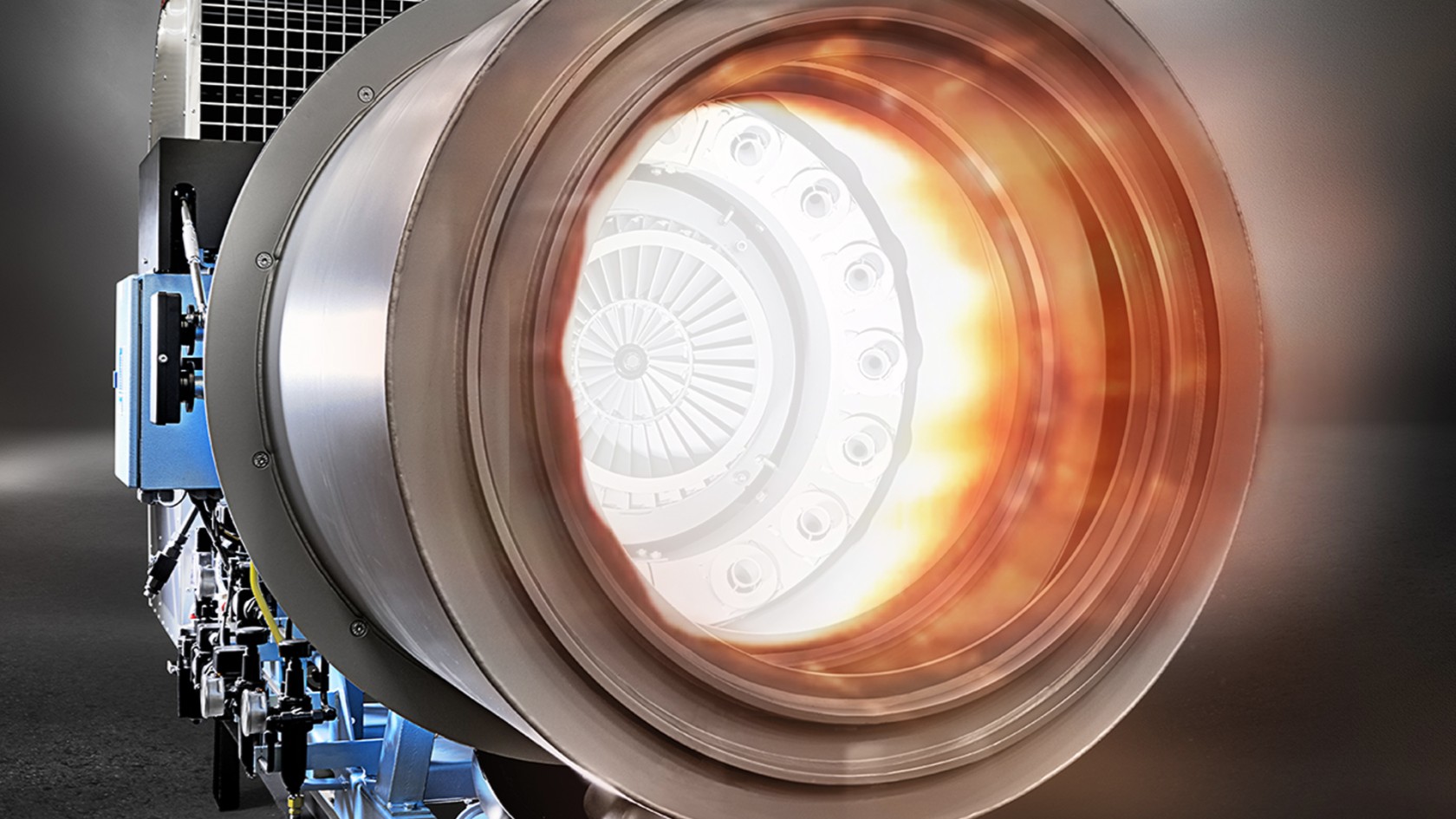

EVO JET

The burner is one of the most important components in any asphalt mixing plant. This is because the burner is a prerequisite for optimum mineral drying results and therefore the quality of the mixture.

For the design and construction of its famed EVO JET burners, BENNINGHOVEN – the newest member of WIRTGEN GROUP – draws on a wealth of expertise that is unequalled anywhere in the world. One key reason for this is that, shortly after its formation in 1909, the company started making burners for a wide range of applications, later inventing fully automatic ignition with photocell flame monitoring. This innovation was behind the company’s move into the production of asphalt mixing plants in 1978. Today, the company is still the only asphalt plant maker with its own burner manufacturing unit.

Peter Koltes, Head of Combustion Technology at BENNINGHOVEN

Over the years, EVO JET burners have earned themselves a legendary reputation and continue to be a key factor in BENNINGHOVEN’s success as a company. Peter Koltes, Head of Combustion Technology at BENNINGHOVEN, explains the benefits: “The burners are not only incredibly reliable, but are the only burners on the market that can be operated using up to four kinds of fuel – such as heating oil (extra light, medium and heavy), liquefied gas, natural gas, solid fuel (coal dust) or a combination of different fuels.”

Public Relations

Reinhard-Wirtgen-Straße 2

53578 Windhagen

Germany