Rehabilitating a runway with WITOS Paving Plus

A paving team used WITOS Paving Plus for the first time at Jade-Weser.

Germany | Wilhelmshaven

the team from Georg Koch GmbH used the construction project in Wilhelmshaven as an intensive opportunity to get to know VÖGELE’s networked system solution for process optimization and documentation. The asphalt work consisted of paving the runway, approximately 1,500 m long. A SUPER 1900-3i – equipped with WITOS Paving Plus - was used as the primary paver to pave two asphalt base courses (pre-profile and base course). For the final paving operation, namely the surface course, three SUPER pavers worked “hot to hot”.

The highlight of the project for all those involved was the advance in productivity achievable with WITOS Paving Plus, asthe innovative VÖGELE solution enabled the pavers to operate continuously. The experienced paving team was delighted to find that fewer mix trucks than planned were actually required. WITOS Paving thus very quickly demonstrated the scale of the optimization potential it opens up for customers and users. “When you see how you can get a little bit better every day, it’s incredibly motivating,” said Senior Site Manager, Tim Gassmann.

The positive impression made on the Georg Koch GmbH team is not surprising, as the five different WITOS Paving modules network the supervisors at the asphalt mixing plant, the truck drivers from the transport company and the whole paving team on site. The system gives planning engineers and site managers a full overview of the current project.

Potential disruptions and obstacles to the construction process are picked up more quickly, which gives those involved more options for dealing with them. Staff are put in a position where they can take immediate measures to optimize the job site and remedy deviations from the planned workflow in real time.

“When you see how you can get a little bit better every day, it’s incredibly motivating,” said Tim Gassmann, senior site manager at Georg Koch GmbH, who is convinced of the benefits of WITOS Paving Plus.

The asphalt runway at Jade-Weser Airport consists of two asphalt base courses and one surface course. The lower courses were paved by a SUPER 1900-3i. This tracked paver was equipped with WITOS Paving Plus. The primary paver was supported by a SUPER 1600-3i and a SUPER 1800-3i for the final paving stage, the surface course. The machines worked “hot to hot” with an overlap of around 20cm – and thus without joints.

The paving strips were selected so as not to create a centre joint: the SUPER 1900-3i worked a width of 7.5 m in the centre of the runway and paved a crown. Beside it, the two other VÖGELE pavers paved two strips with a transverse slope, creating a width of 15 m.

The primary paver finally paved the outer strips, making a total width of 30m. The fact that it was possible to work practically continuously throughout was due not least to the use of WITOS Paving Paving Plus.

”The system impressed us a lot right back at the planning stage, because it simply calculated a lot of the values itself - for example, the quantity of asphalt required. If the capacity of the planned mixing plant is too low, the system issues a warning,” said Tim Gassmann. This was also the case with a number of the planned strips in Wilhelmshaven. It was demonstrated by the calculation completed by the WITOS Paving Control Paving Control planning and control module – and was why the senior site manager arranged a second mixing plant in good time to cover peak demand.

Ease of operation is at least as important as accurate function. “WITOS Paving is extremely practical. It can simply be used, whatever the weather. The software functions are easy to understand. As a result I was quickly able to see what key added value the system offers. I wouldn’t want to be without it now,” insisted works supervisor Theo Hülsmayer, who operated the WITOS Paving Paving Plus JobSite module on an outdoor PC on the job site itself. This visualized all the key paving parameters for him on a tablet or outdoor PC.

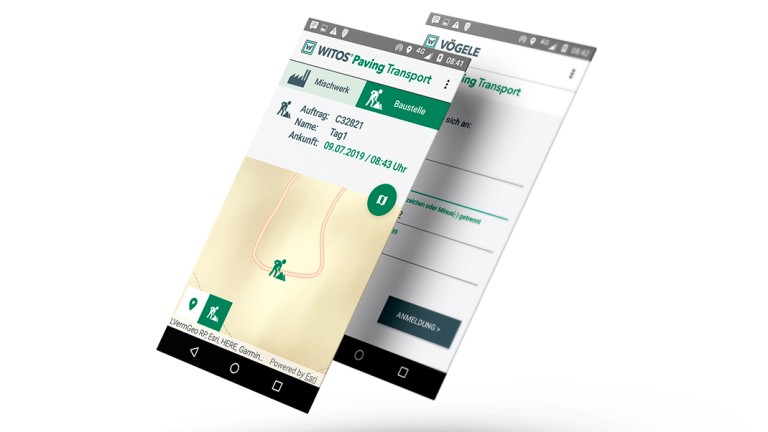

The Transport module is intended for truck drivers and is supplied in the form of an app.

A particularly clear example of the value WITOS Paving Plus adds for users and clients is improved planning of the trucks required: according to the system, 13 mix trucks were needed on the first paving day to supply the three VÖGELE pavers with mix. The Koch team initially trusted in its own experience and used 15 trucks. The evaluation then followed. On WITOS Paving Plus, this is carried out in the Analysis module, the statistics and documentation tool. This enables construction projects to be assessed objectively and enables contractors to learn from each day’s paving operations and gain information for the next day.

Valuable extra information for Georg Koch GmbH derived from the statistics was that 13 trucks really would have been sufficient – two less than were actually used. For the next day’s paving operations, therefore, site management ordered only the number of mix trucks calculated by WITOS Paving Plus - saving cash every day as a result of this step alone. Despite the reduced number of trucks, there were no interruptions.

The job site reports from Jade-Weser Airport:

Job site report 1: situation on Day 1 using WITOS Paving Plus

Job site report 2: situation on Day 7 using WITOS Paving Plus

Conclusion

With WITOS Paving Plus, the paving team from Georg Koch GmbH achieved the following productivity increases:

*Using insulated dump trucks in combination with short transport routes meant that the longer waiting time on Day 1 had no negative impact on paving temperature.

Non-contacting temperature-measurement system