Central mixing method (in-plant)

The in-plant mixing method involves transporting milled asphalt material and broken stone to a mixer unit located near the construction site. There, the milled material is prepared with binder to make a new construction material mixture, and it is re-used either at the same construction site or at another.

In-plant cold recycling is appealing if:

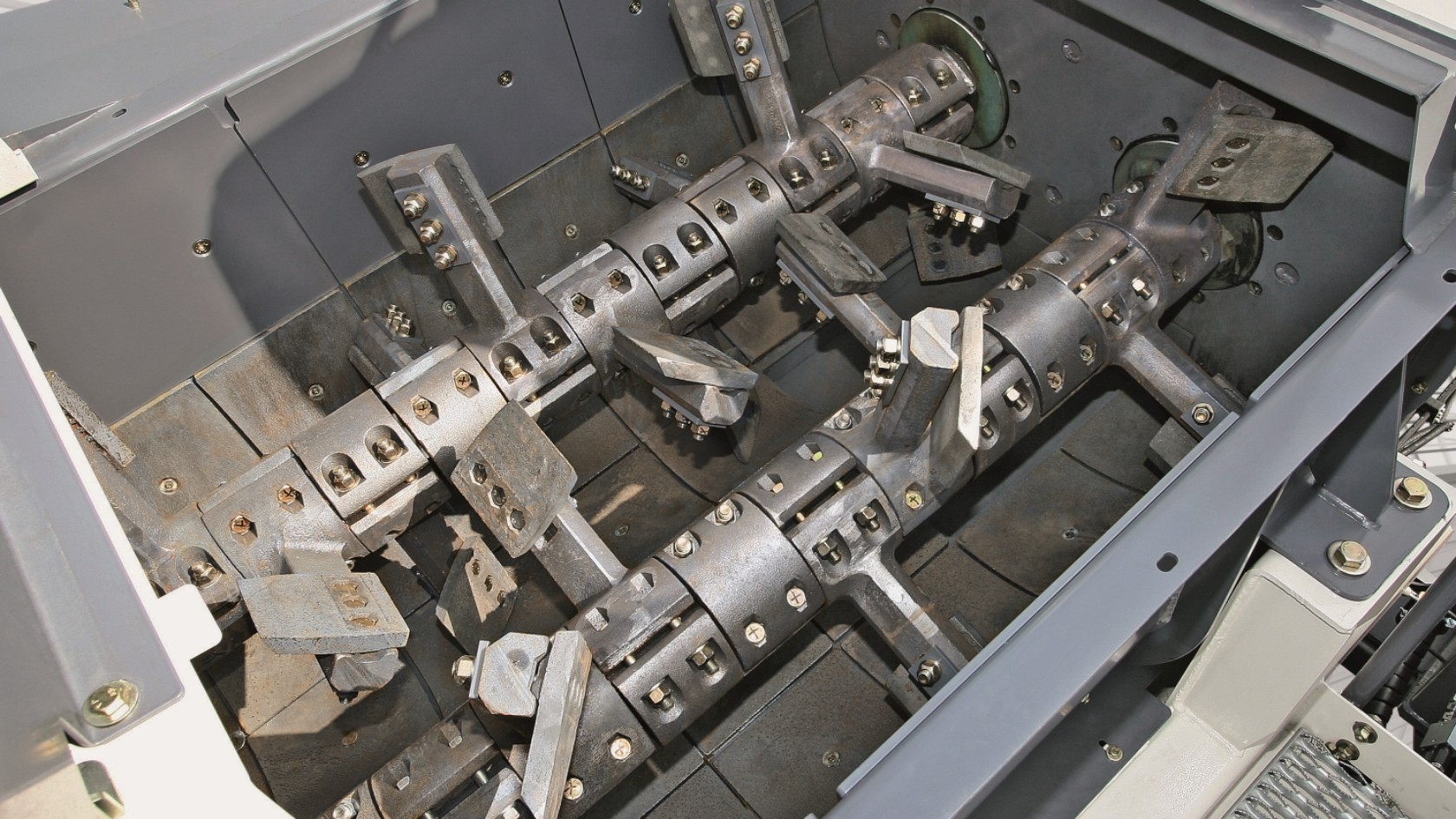

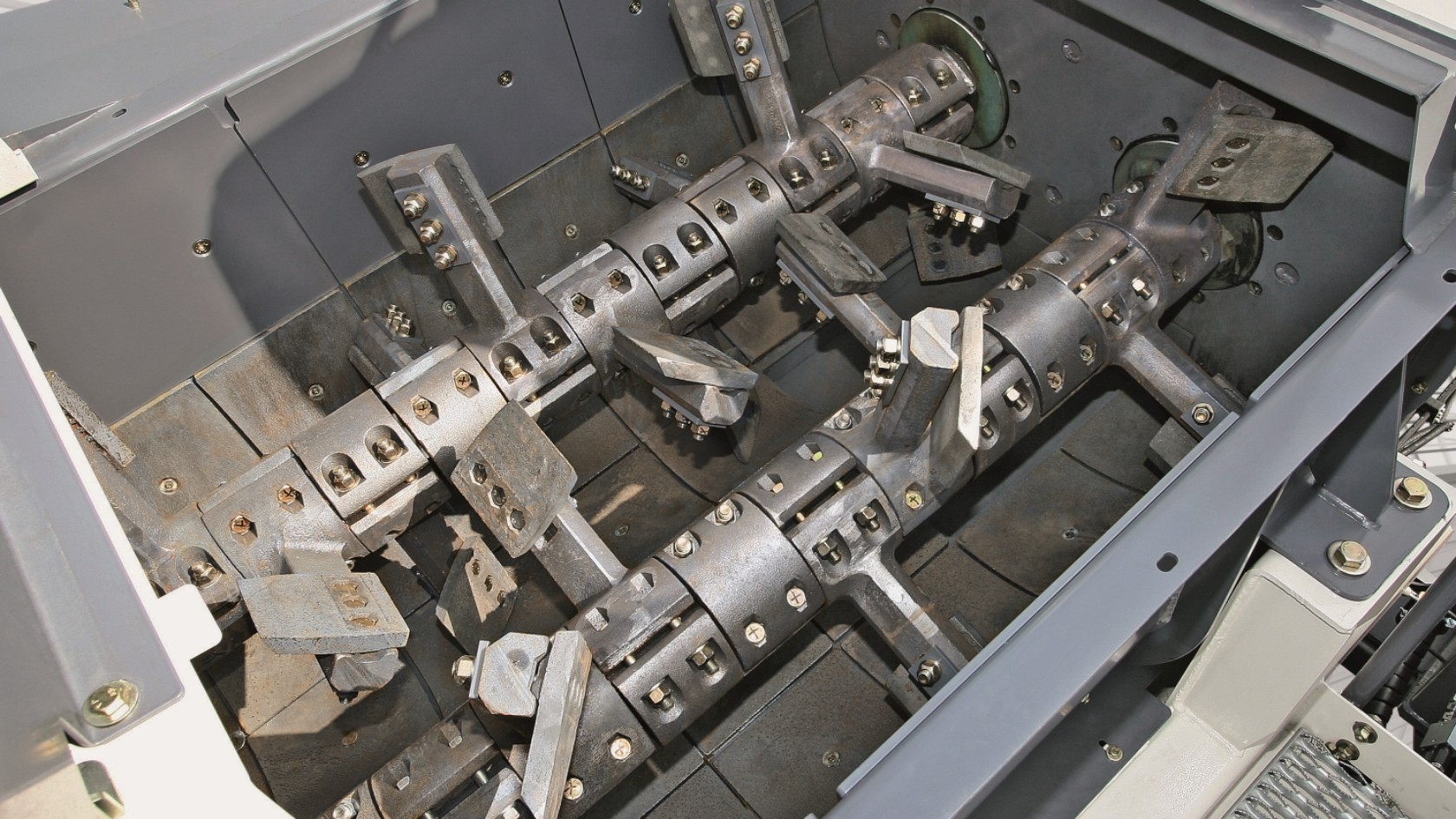

To produce absolutely homogeneous mixtures, the mobile cold recycling mixer units KMA 220 / KMA 220i have a powerful dual-shaft compulsory mixer. It is equipped with specially arranged mixing arms and mixing blades made of hard metal that is highly wear-resistant. The mixing container is provided with special wear plates.

The mixing paddles and interior of the compulsory mixer are made of material that is highly wear-resistant The mixing paddles can be adjusted separately and can be individually replaced. The mixer and all other components are driven fully hydraulically by a powerful diesel engine. The rugged, dual-shaft, continuous-flow mixer enables a homogeneous mixing output of 220 metric tons per hour.