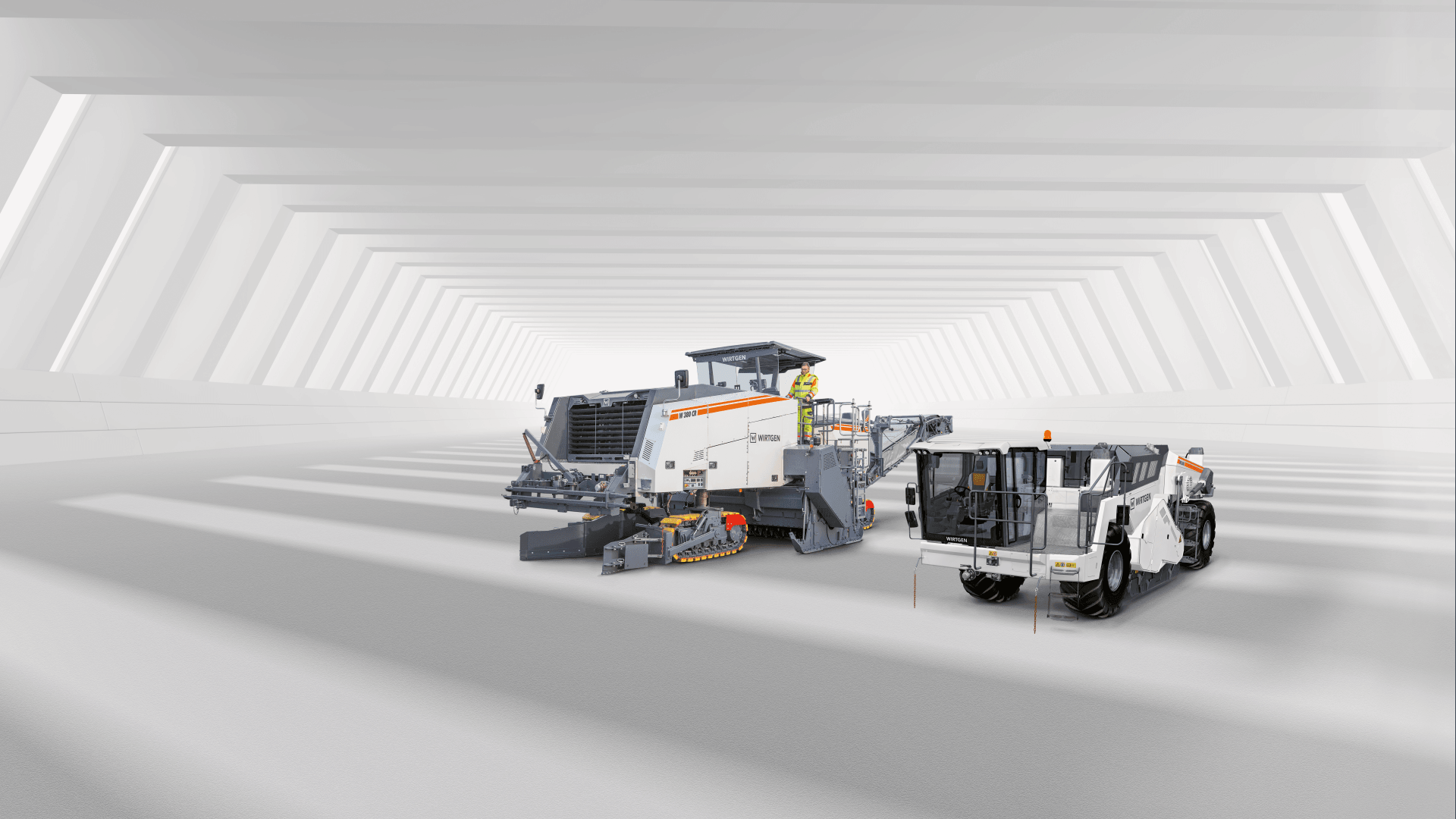

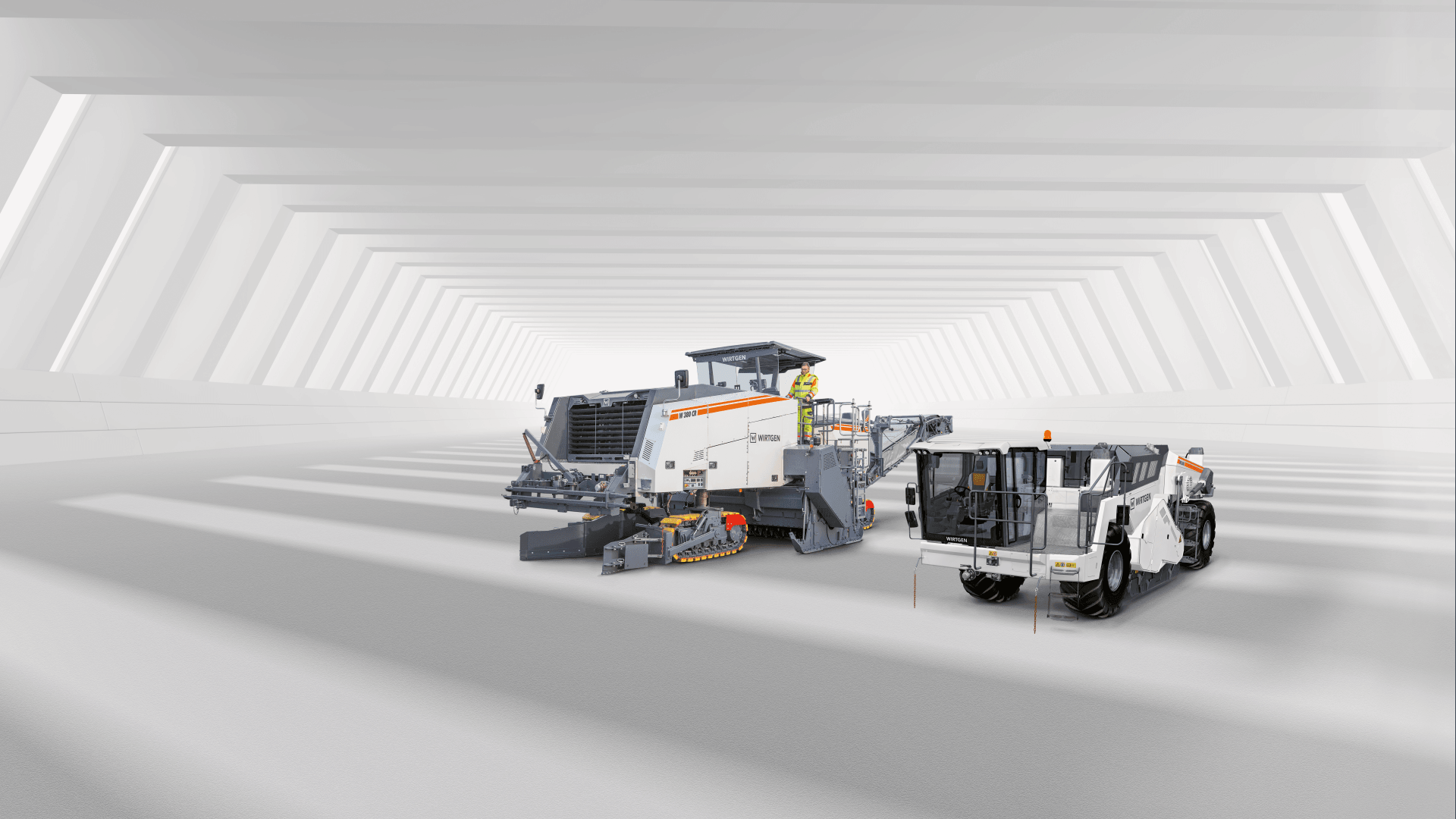

Recyclers and soil stabilizers

Cold recyclers are used to prepare asphalt pavement on site. In this process, the existing pavement is granulated with the milling and mixing rotor and prepared by adding precise amounts of bituminous binding agents, cement and water. The result is a homogeneous material that can be used to directly repave the soil. Soil stabilisers use the milling and mixing rotor to mix pre-spread binding agents such as lime or cement into the existing, less stable soil and transform it into a high-quality material directly on site.

The WS series tractor-towed stabilizers can be coupled to a tractor (minimum engine power output >220 kW) in a just a couple of easy steps. The adjustable rotor plate ensures homogeneous mixing quality. Side plates on skids, mechanical belt drives on each side, and an effective milling and mixing rotor all contribute to their high performance. Tractor-towed stabilizers are typically used for soil stabilization or consolidation in the construction of traffic infrastructure.

Tractor-towed stabilizers

| Working width max. | 8 ft 2 in |

| Working depth | 20 in |

The WR series cold recyclers and stabilizers have a variable mixing chamber and microprocessor-controlled injection systems for the addition of bitumen emulsion, water, or foamed bitumen. Thanks to an efficient hydraulic flow divider, the all-wheel drive provides maximum traction, while the four-fold full-floating axles ensures best possible ground clearance in challenging terrain. The WR series machines are therefore ideal for a variety of application scenarios ranging from cold recycling - structural road rehabilitation - to the stabilization of various construction materials such as, for example, in soil stabilization or consolidation in the construction of traffic infrastructure.

The WRC series machines feature a high-performance crushing and mixing unit with specially developed HT18 crushing tools that enables the crushing and homogenization of rocks, stones, hand-packed stone pavement layers, concrete rubble, or cobblestones. These machines also have a variable mixing chamber and an optional microprocessor-controlled injection system for the addition of water. This enables binding agents and water to be added and mixed in during crushing and homogenization. Thanks to an efficient hydraulic flow divider, the all-wheel drive provides maximum traction, while the four-fold full-floating axles ensures best possible ground clearance in challenging terrain. The WRC series machines are designed and constructed for processing unbound materials and less cohesive soils interspersed with coarse rocks or stones by crushing and homogenization: cultivation (soil improvement/agriculture), road construction (crushing of concrete fragments and hand packed stone pavement layers), soil treatment/soil stabilization, maintenance of opencast mine and quarry roadways, etc.

CR series cold recyclers are used for efficient and cost-effective cold recycling of road pavements. Optional, microprocessor-controlled injection systems enable precisely controlled addition of water, bitumen emulsion, or foamed bitumen. Thanks to the machine concept, these cold recyclers enable selective granulation and homogenization of the surface layer across the full road width. Using the down-cut method ensures ideal gradation of the material. After granulation and homogeneous mixing with the binding agent, the cold recycler transfers the processed construction material to the material hopper of the downstream asphalt paver with its integrated discharge conveyor. CR series cold recyclers can also be used as high-performance milling machines.

The mobile cold mixing plants of the KMA series are easily transportable and can be quickly set up in close proximity to the project site. The heavy-duty twin-shaft pugmill mixer achieves high mixing performance. Microprocessor-controlled injection systems for the addition of a wide range of binding agents ensure that the materials are mixed precisely to formula. The wide slewing angles of the discharge conveyor enable the processed cold mix to be stockpiled or continuously loaded onto transport vehicles.

Cold recycling projects are often varied and challenging. The laboratory equipment assists with the preparation of samples for the analysis and determination of the properties of the construction materials produced in cold recycling. WIRTGEN offers a range of equipment for this purpose: The WLB 10 S for testing the properties of the foamed bitumen produced by the addition of water, the WLM 30 laboratory-scale mixer with a capacity of 30 kg, and the WLV 1 laboratory compactor are used for the production of test specimens from bitumen-stabilized material.

Innovative laboratory equipment

| Bitumen temperature | 284 - 392°F |

| Own weight | 595 lbs |

Innovative laboratory equipment

| Mixing capacity | 66 lbs |

| Own weight | 485 lbs |

Innovative laboratory equipment

| Impact energy, max. | 23 J |

| Own weight | 375 lbs |

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.