SB 350 Fixed-width screed

TV, TP1, TP2

3.50 m - 18.00 m

3,5

m

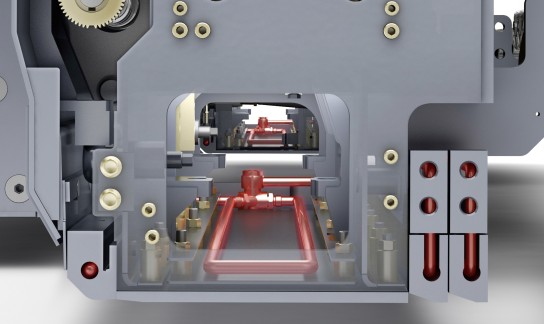

The most powerful screed in the VÖGELE product range

Fixed-width screeds from VÖGELE deliver absolutely high-quality, perfectly even results. Their strengths come to the fore when laying down asphalt across pave large widths and thick base courses. The SB 350 Fixed-Width Screed was specially designed for the SUPER 3000-3(i). They offer a wide range of applications, covering pave widths of 3.5 m to 18 m and layer thicknesses of up to 50 cm.

Show lessTechnical specifications

- Basic width

- Minimum pave width

- Maximum pave width

- Bolt-on extensions

- Bolt-on extensions, hydraulically adjustable

-

- Basic width

- 3,5 m

- Minimum pave width

- 3,5 m

- Maximum pave width

- 18 m

- Bolt-on extensions

-

Length 25 cm 50 cm 100 cm 150 cm

- Bolt-on extensions, hydraulically adjustable

- 125 cm

- Version

- Crown adjustment

-

- Version

- mechanical

- Crown adjustment

- -2 % to 3 %

- Compacting systems

- Vibrators (V)

- Version

- Frequency (max.)

- Tamper (T)

- Speed (max.)

- Stroke, standard (TV, TP1, TP2)

- Stroke, optional hydraulic (TV, TP1, TP2)

- Pressure bars (P)

- Pressure bar drive (P)

- Pressure bar pulse frequency (P) (max.)

- Hydraulic oil pressure (max.)

-

- Compacting systems

- TV, TP1, TP2

- Version

- eccentric vibrators

- Frequency (max.)

- 50 Hz

- Speed (max.)

- 1.800 U/min

- Stroke, standard (TV, TP1, TP2)

- 2 mm, 4 mm, 7 mm

- Stroke, optional hydraulic (TV, TP1, TP2)

- 4 mm, 8 mm

- Pressure bar drive (P)

- pulsed hydraulic

- Pressure bar pulse frequency (P) (max.)

- 68 Hz

- Hydraulic oil pressure (max.)

- 120 bar

- Heating rods

- Output generation

- Optional screed heating

- Control

-

- Heating rods

- on screed plates and in tamper bars and pressure bars

- Output generation

- three-phase AC generator

- Optional screed heating

- function monitoring of each individual heating rod

- Control

- fully automatic, thermostat-controlled

- Width (without side plate)

- Basic screed weight

- Depth (in transport position)

-

- Width (without side plate)

- 3,5 m

- Basic screed weight

-

Screed Weight TV 2.500 kg TP1 2.750 kg TP2 2.900 kg

- Depth (in transport position)

-

Screed Depth SB 350 1,34 m

Downloads

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.