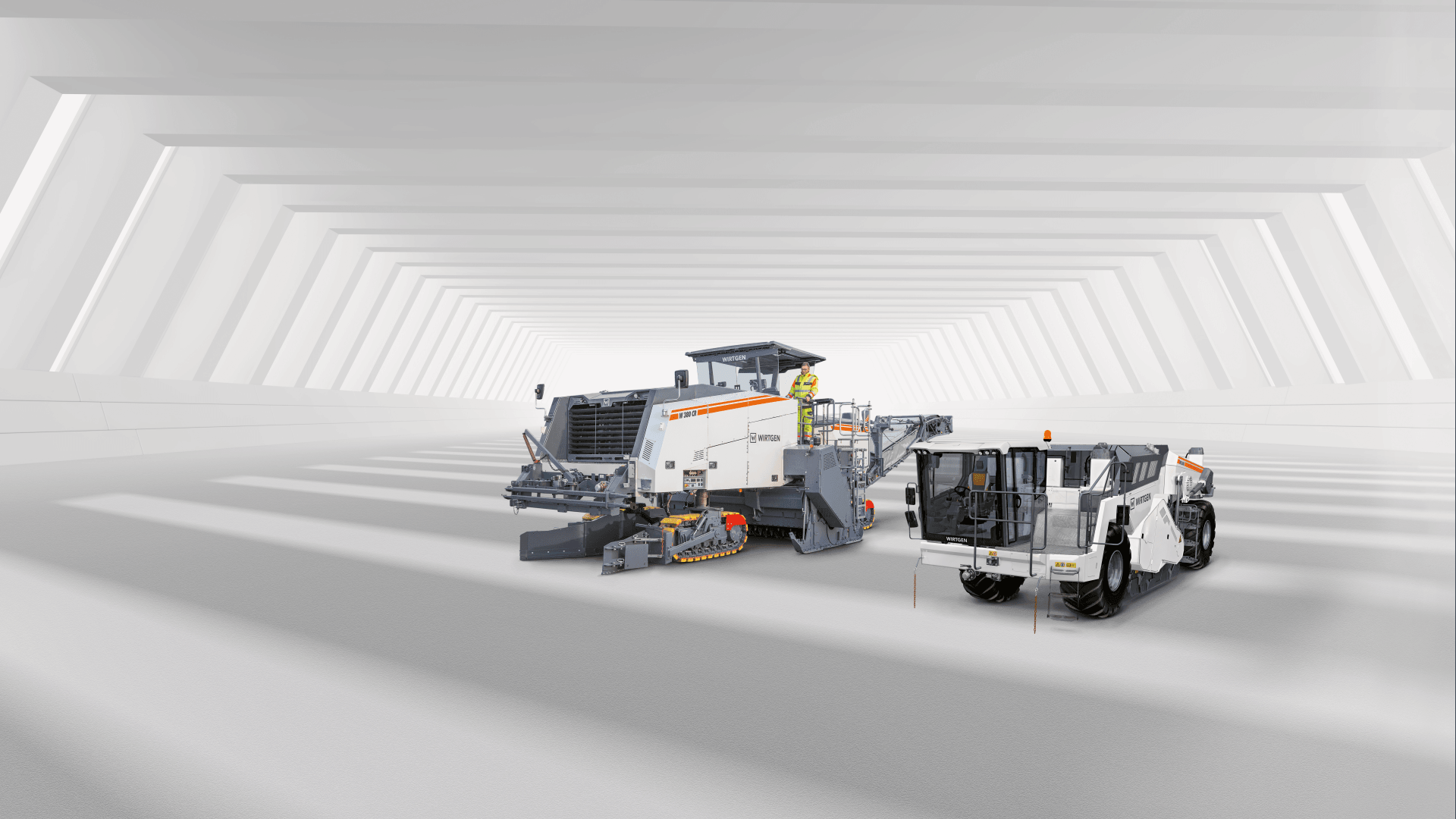

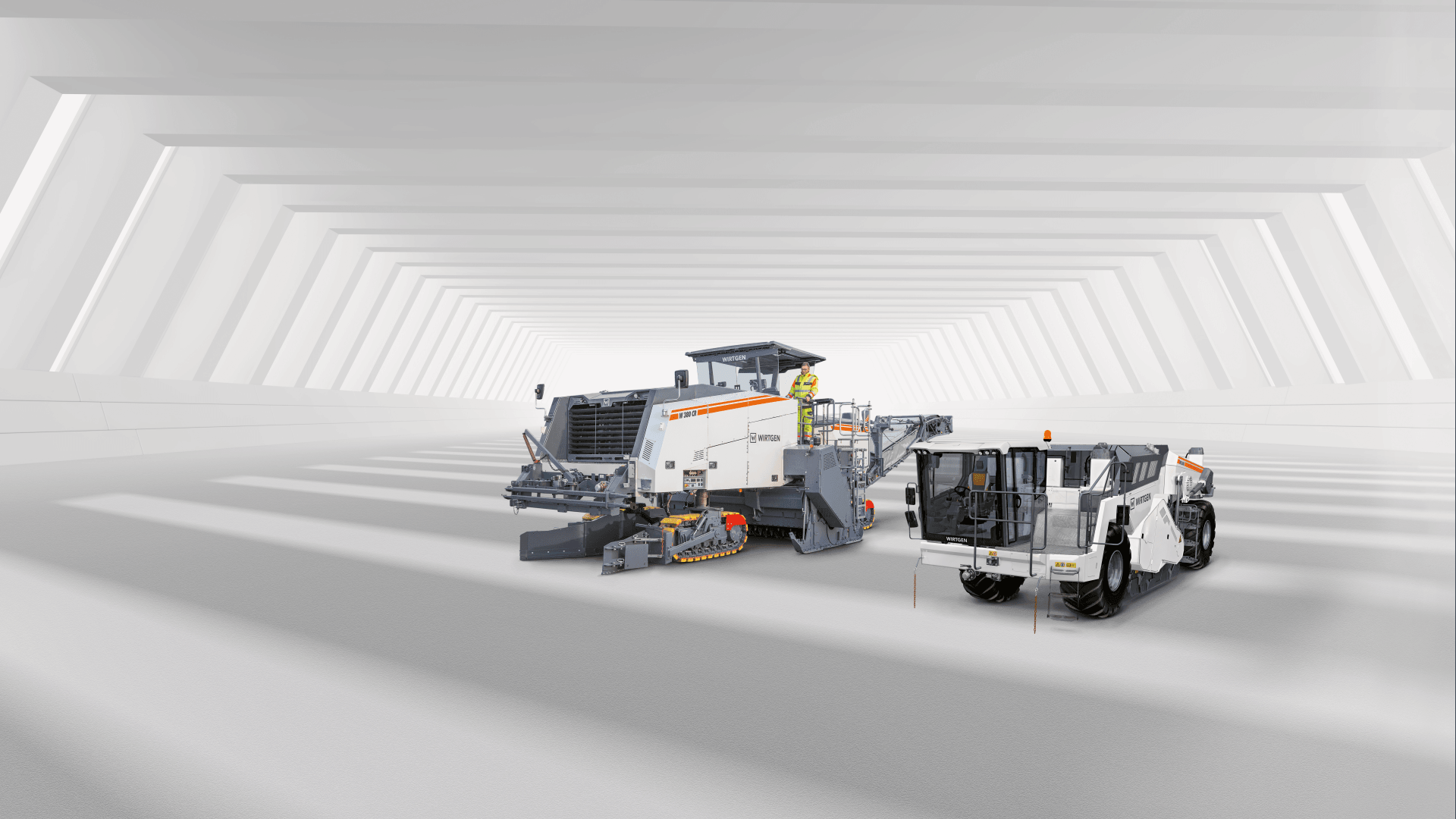

Recyclers and soil stabilizers

Cold recyclers are used to prepare asphalt pavement on site. In this process, the existing pavement is granulated with the milling and mixing rotor and prepared by adding precise amounts of bituminous binding agents, cement and water. The result is a homogeneous material that can be used to directly repave the soil. Soil stabilisers use the milling and mixing rotor to mix pre-spread binding agents such as lime or cement into the existing, less stable soil and transform it into a high-quality material directly on site.

Cold recycling projects are often varied and challenging. The laboratory equipment assists with the preparation of samples for the analysis and determination of the properties of the construction materials produced in cold recycling. WIRTGEN offers a range of equipment for this purpose: The WLB 10 S for testing the properties of the foamed bitumen produced by the addition of water, the WLM 30 laboratory-scale mixer with a capacity of 30 kg, and the WLV 1 laboratory compactor are used for the production of test specimens from bitumen-stabilized material.

Innovative laboratory equipment

| Bitumen temperature | 140 - 200°C |

| Own weight | 270 kg |

Innovative laboratory equipment

| Mixing capacity | 30 kg |

| Own weight | 220 kg |

Innovative laboratory equipment

| Impact energy, max. | 23 J |

| Own weight | 170 kg |

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.