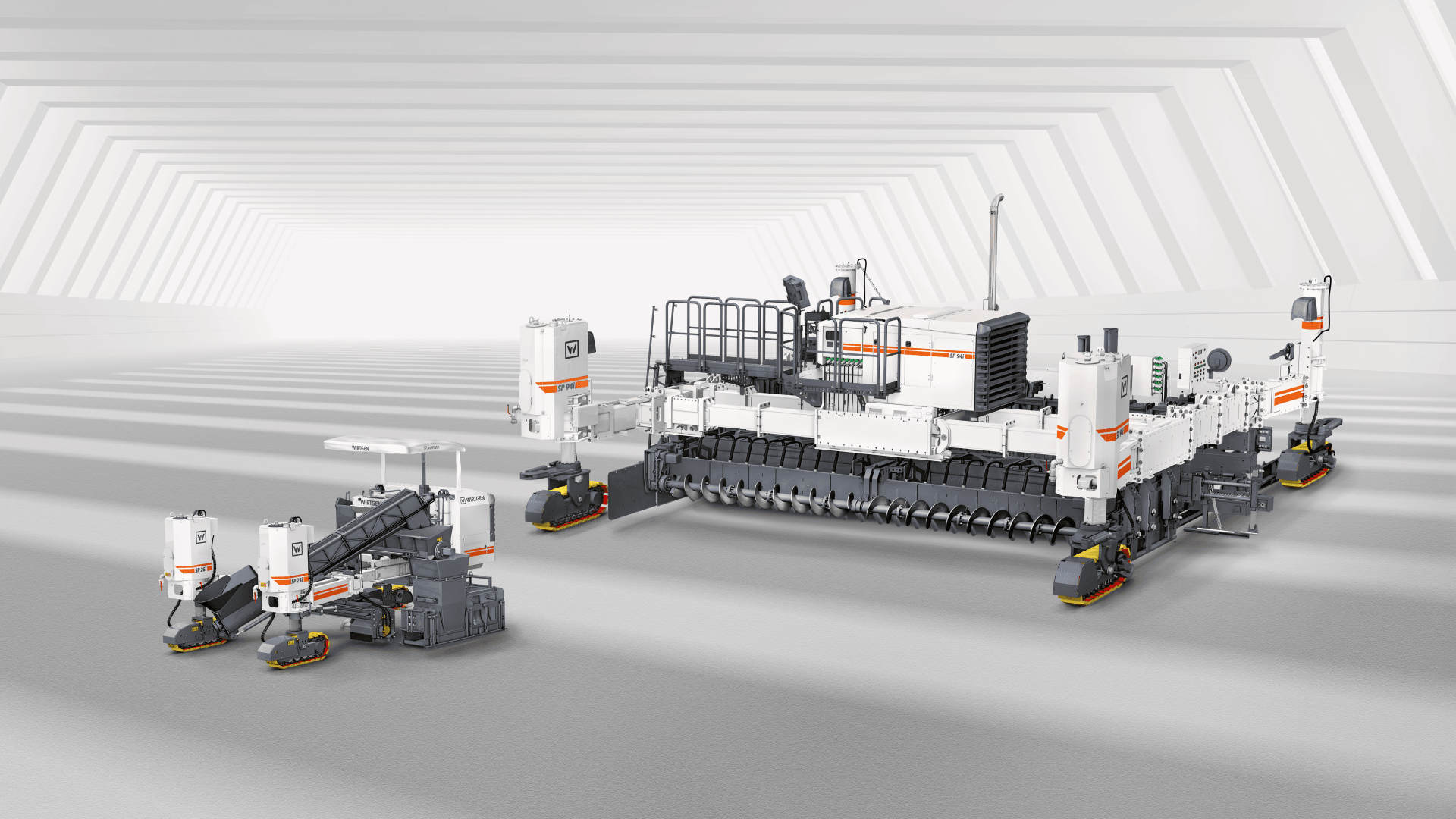

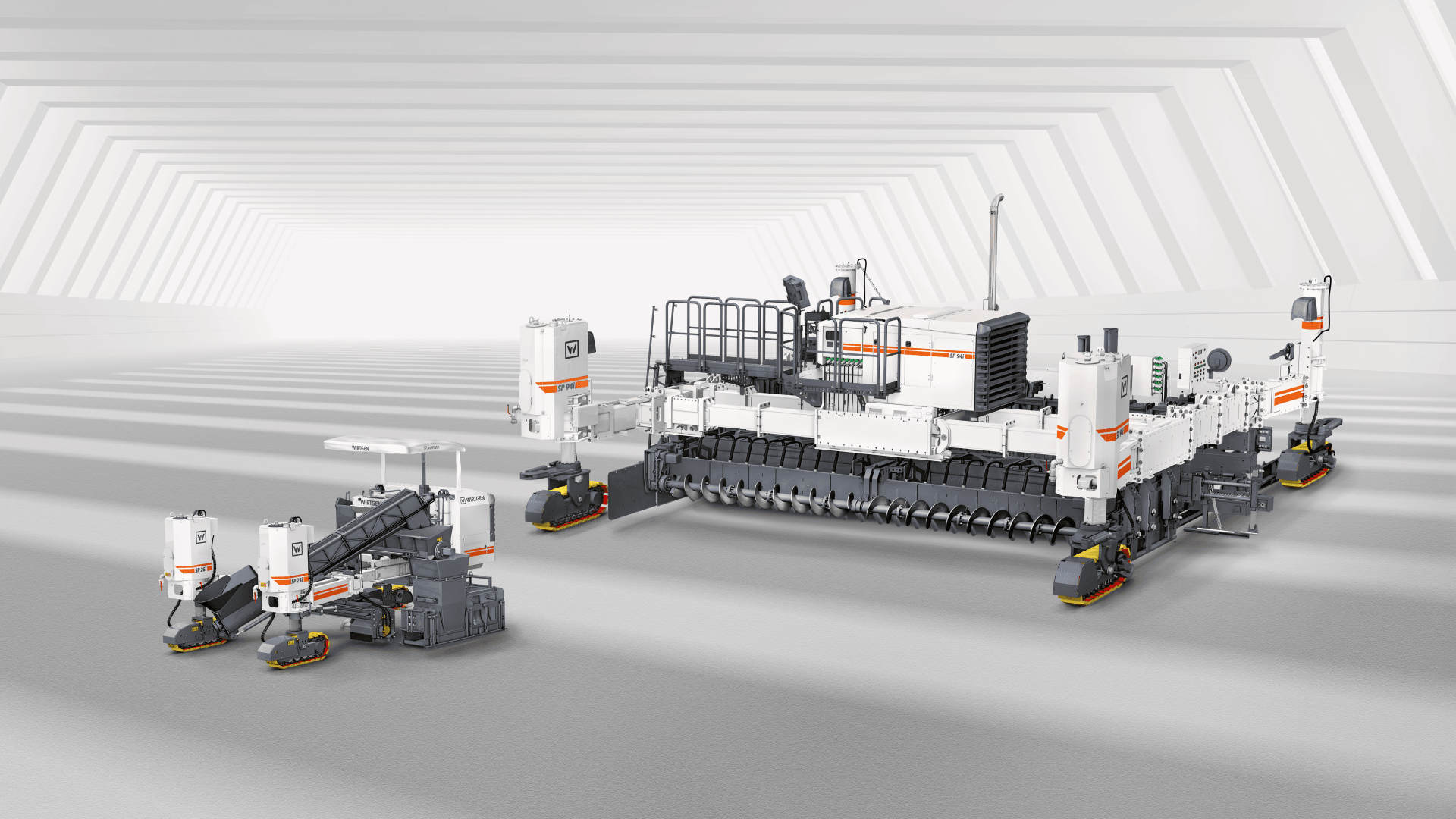

Slipform pavers

Offset pavers are used to produce monolithic concrete profiles such as protective concrete walls, kerb profiles, gutters or narrow paths. Thanks to numerous options, such as for concrete feeding or slipforming, offset slipform pavers are extremely versatile. Inset pavers cost-effectively produce concrete pavements, such as for motorways, arterial roads, runways or railway lines. In addition to single-layer concrete paving, bottom-layer and top-layer concrete can also be paved synchronously in two layers ‘wet on wet’.

If reinforcement needs to be laid in advance during the construction of concrete roadways, the concrete can be fed in laterally using a placer/spreader. The placer/spreader travels in front of the slipform paver over the pre-placed reinforcement, while a truck mixer feeds the belt conveyor with concrete from the side. The concrete is poured evenly over the pre-placed reinforcement, in front of the slipform paver, and distributed across the entire working width. Once the truck mixer is empty, the belt conveyor can be folded away in a very short time to clear the path for the next mixer.

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.