MCO 90 EVO2 Mobile cone crusher

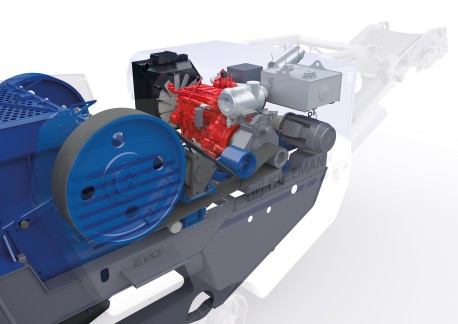

D-DRIVE (Diesel-direct)

200 mm

270

t/h

The MOBICONE MCO 90 EVO2 impresses as a powerful team player in hard stone. Whereas top product quality is expected from a cone crusher, the MCO 90 EVO2 combines this with a high production output. The plant is characterised by the best possible economy, simple operation and innovative overload systems.

Show more Highlights

The MCO 90 EVO2 is powerful, efficient and ideal for use in conjunction with the MC 110 EVO2 mobile jaw crusher.

CFS

Feeding unit

Drive

Overload system

Post screening unit

Accessibility and safety

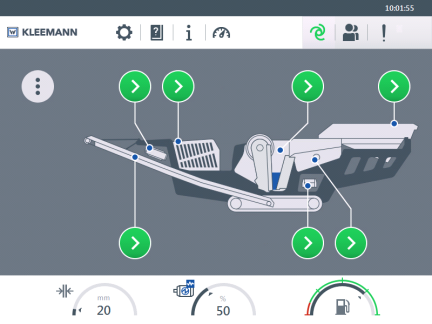

Control system

Crusher unit

Transport

Technical specifications

- Max. feed size

- Feeding height

- Feed height with extension

- Feed capacity up to approx.

- Hopper width

- Hopper width with extension

- Hopper length

- Hopper length with extension

- Hopper volume

- Hopper volume with extension

-

- Max. feed size

- 200 mm

- Feeding height

- 2,680 mm

- Feed height with extension

- 3,240 mm

- Feed capacity up to approx.

- 270 t/h

- Hopper width

- 2,780 mm

- Hopper width with extension

- 3,700 mm

- Hopper length

- 3,000 mm

- Hopper length with extension

- 3,600 mm

- Hopper volume

- 6.4 m³

- Hopper volume with extension

- 8.3 m³

- Width x length

-

- Width x length

- 1,000 mm x 5,900 mm

- Crusher drive type

- Crusher weight (approx.)

- Crushing power

- Crusher system size

- Cone crusher model

-

- Crusher drive type

- Direct

- Crusher weight (approx.)

- 8,900 kg

- Crushing power

- 185 kW

- Crusher system size

- 970 mm

- Cone crusher model

- KX250

- Crushing capacity at 0-32 mm approx.

- Crushing capacity at 0-45 mm approx.

- Crushing capacity at 0-56 mm approx.

- Crushing capacity at 0-63 mm approx.

-

- Crushing capacity at 0-32 mm approx.

- 220 t/h

- Crushing capacity at 0-45 mm approx.

- 245 t/h

- Crushing capacity at 0-56 mm approx.

- 255 t/h

- Crushing capacity at 0-63 mm approx.

- 270 t/h

- Discharge height approx.

- Discharge height, extended approx.

- Width

- Length

- Length, extended

-

- Discharge height approx.

- 3,300 mm

- Discharge height, extended approx.

- 3,700 mm

- Width

- 800 mm

- Length

- 9,100 mm

- Length, extended

- 10,400 mm

- Drive concept

- Rated speed

- Generator

- Power pack manufacturer

- Power supply unit output

-

- Drive concept

- D-DRIVE (Diesel-direct)

- Rated speed

- 1,500 U/min

- Generator

- 135 kVA

- Power pack manufacturer

- Scania

- Power supply unit output

- 289 kW - 289 kW

- Discharge height fine grain discharge conveyor approx.

- Width x length approx.

- Model

- Oversize grain return conveyor width

- Oversize grain return conveyor length

-

- Discharge height fine grain discharge conveyor approx.

- 3,500 mm

- Width x length approx.

- 1,350 mm x 4,000 mm

- Model

- Vibrating single-deck screen

- Oversize grain return conveyor width

- 500 mm

- Oversize grain return conveyor length

- 9,000 mm

- Transport height approx. (default value)

- Transport length approx.

- Transport length with secondary screening unit approx.

- Transport width approx.

- Transport width with secondary screening unit max.

- Transport weight of basic plant approx.

- Transport weight max. configuration approx.

- Transport weight of screening unit approx.

-

- Transport height approx. (default value)

- 3,400 mm

- Transport length approx.

- 16,050 mm

- Transport length with secondary screening unit approx.

- 20,200 mm

- Transport width approx.

- 3,000 mm

- Transport width with secondary screening unit max.

- 3,240 mm

- Transport weight of basic plant approx.

- 43,500 kg

- Transport weight max. configuration approx.

- 46,500 kg

- Transport weight of screening unit approx.

- 6,100 kg

- Width x length

- Type

- Return conveyor width

- Return conveyor length

- Side discharge conveyor (medium grain) width

- Side discharge conveyor (medium grain) length

- Side discharge conveyor (medium grain) discharge height

-

- Width x length

- 1350 mm x 4550 mm

- Type

- Double-deck light-piece screen

- Return conveyor width

- 500 mm

- Return conveyor length

- 9,000 mm

- Side discharge conveyor (medium grain) width

- 500 mm

- Side discharge conveyor (medium grain) length

- 6,300 mm

- Side discharge conveyor (medium grain) discharge height

- 3,000 mm

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.