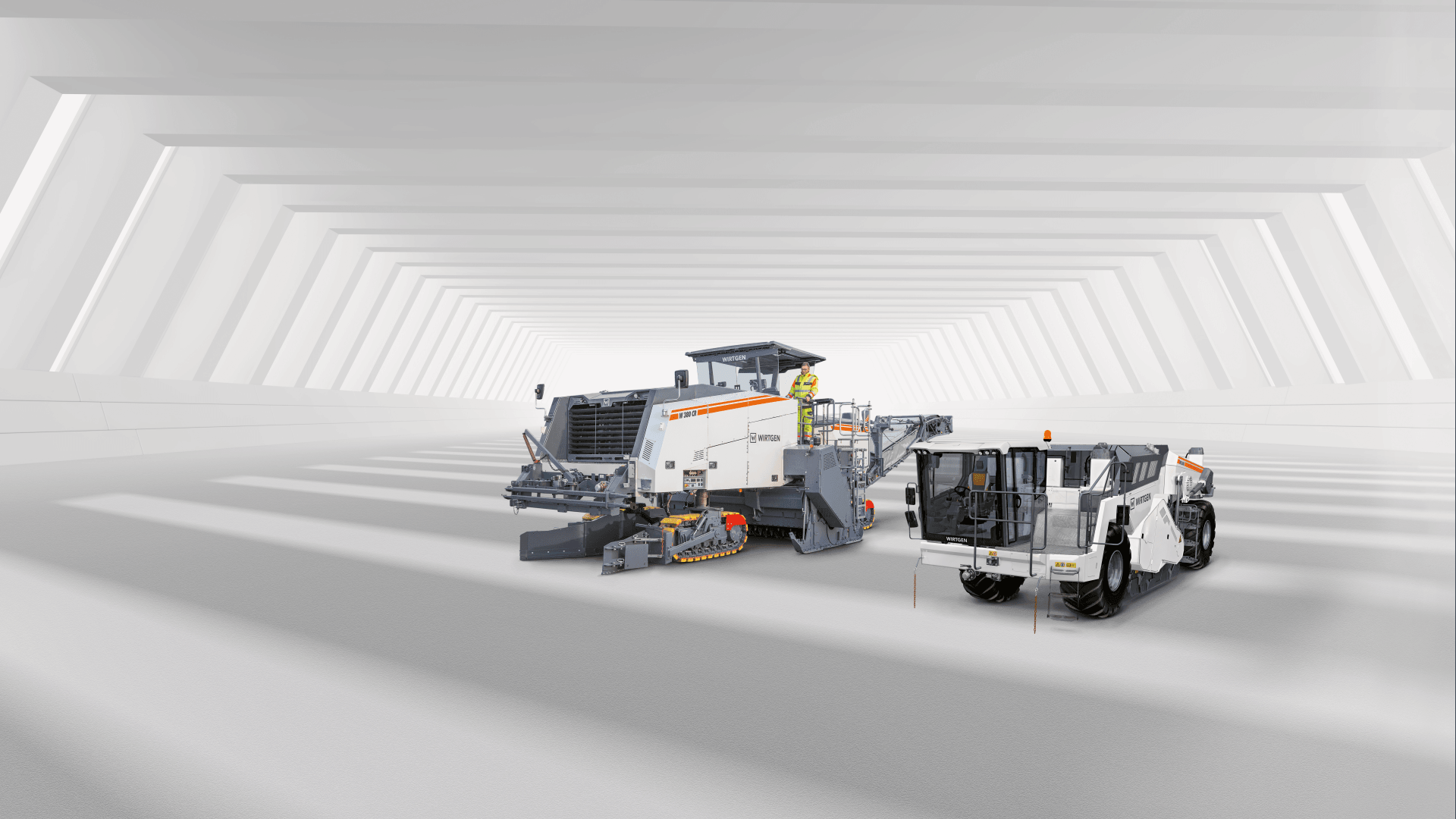

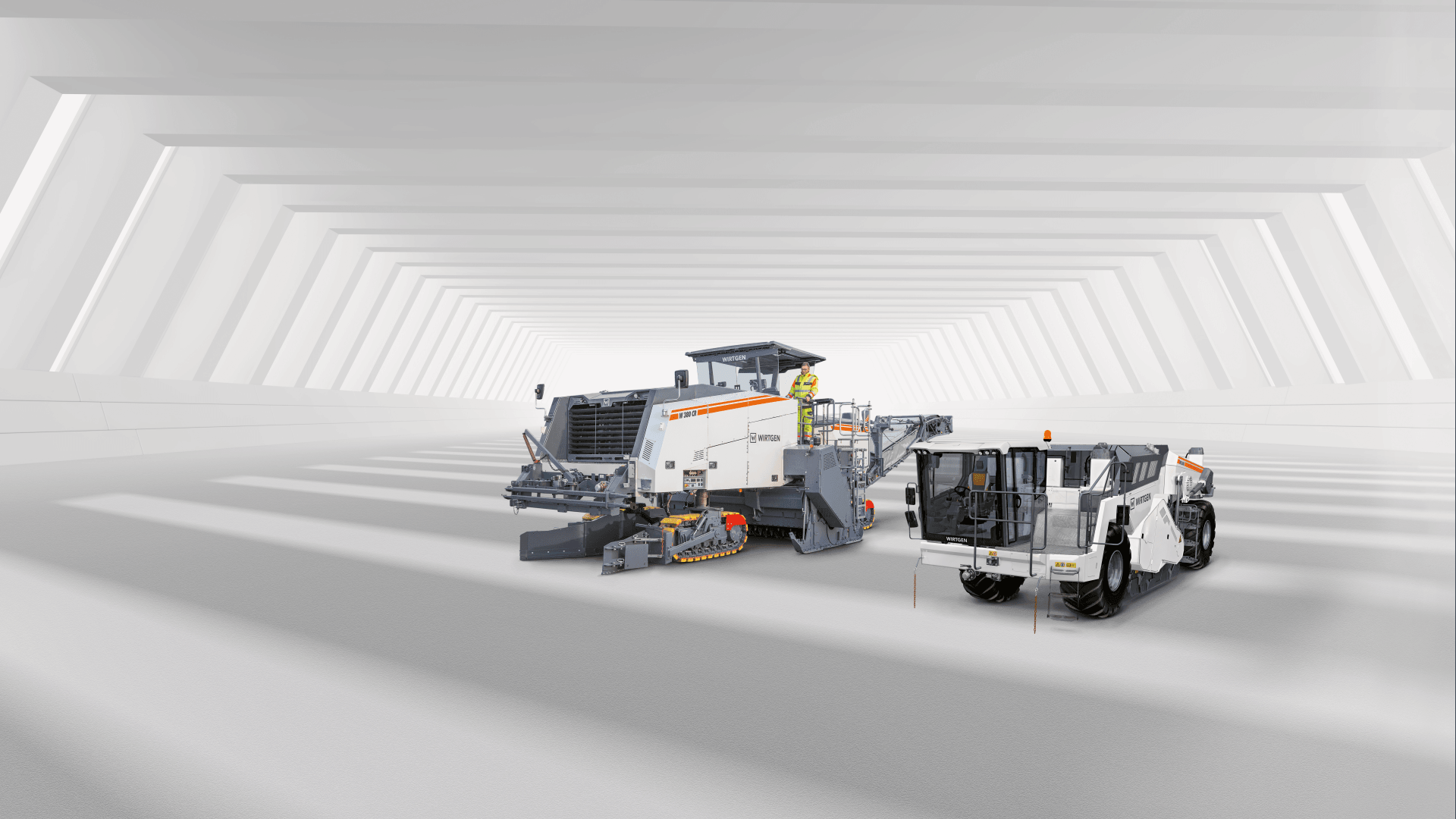

Recyclers and soil stabilisers

Cold recyclers are used to prepare asphalt pavement on site. In this process, the existing pavement is granulated with the milling and mixing rotor and prepared by adding precise amounts of bituminous binding agents, cement and water. The result is a homogeneous material that can be used to directly repave the soil. Soil stabilisers use the milling and mixing rotor to mix pre-spread binding agents such as lime or cement into the existing, less stable soil and transform it into a high-quality material directly on site.

The mobile cold mixing plants of the KMA series are easily transportable and can be quickly set up in close proximity to project sites. The heavy-duty twin-shaft pugmill mixer achieves high mixing performance. Microprocessor-controlled injection systems for the addition of a wide range of binding agents ensure that the materials are mixed precisely to the required recipe. The wide slewing angles of the discharge conveyor enable the processed cold mix to be stockpiled or continuously loaded onto transport vehicles.

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.