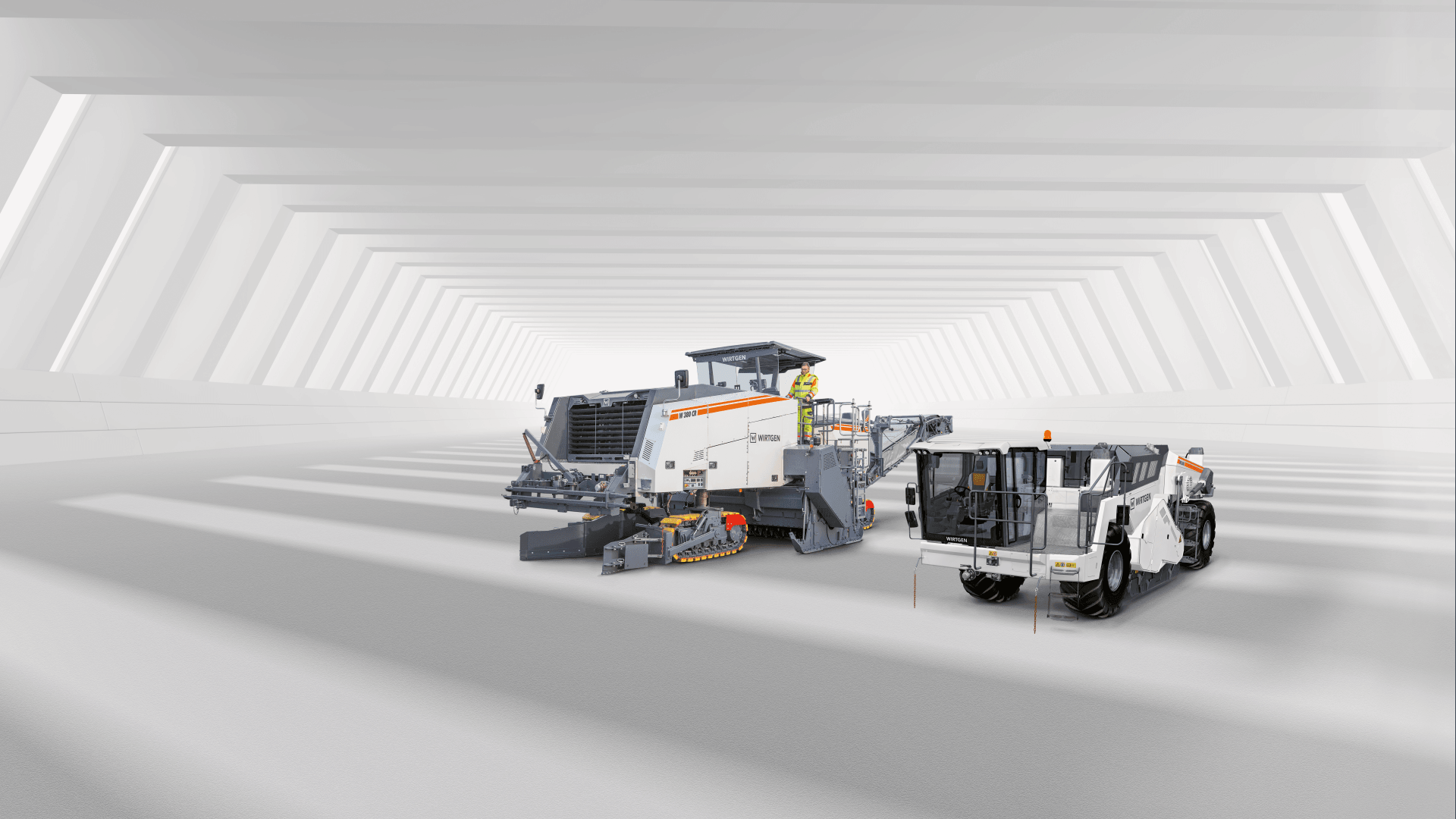

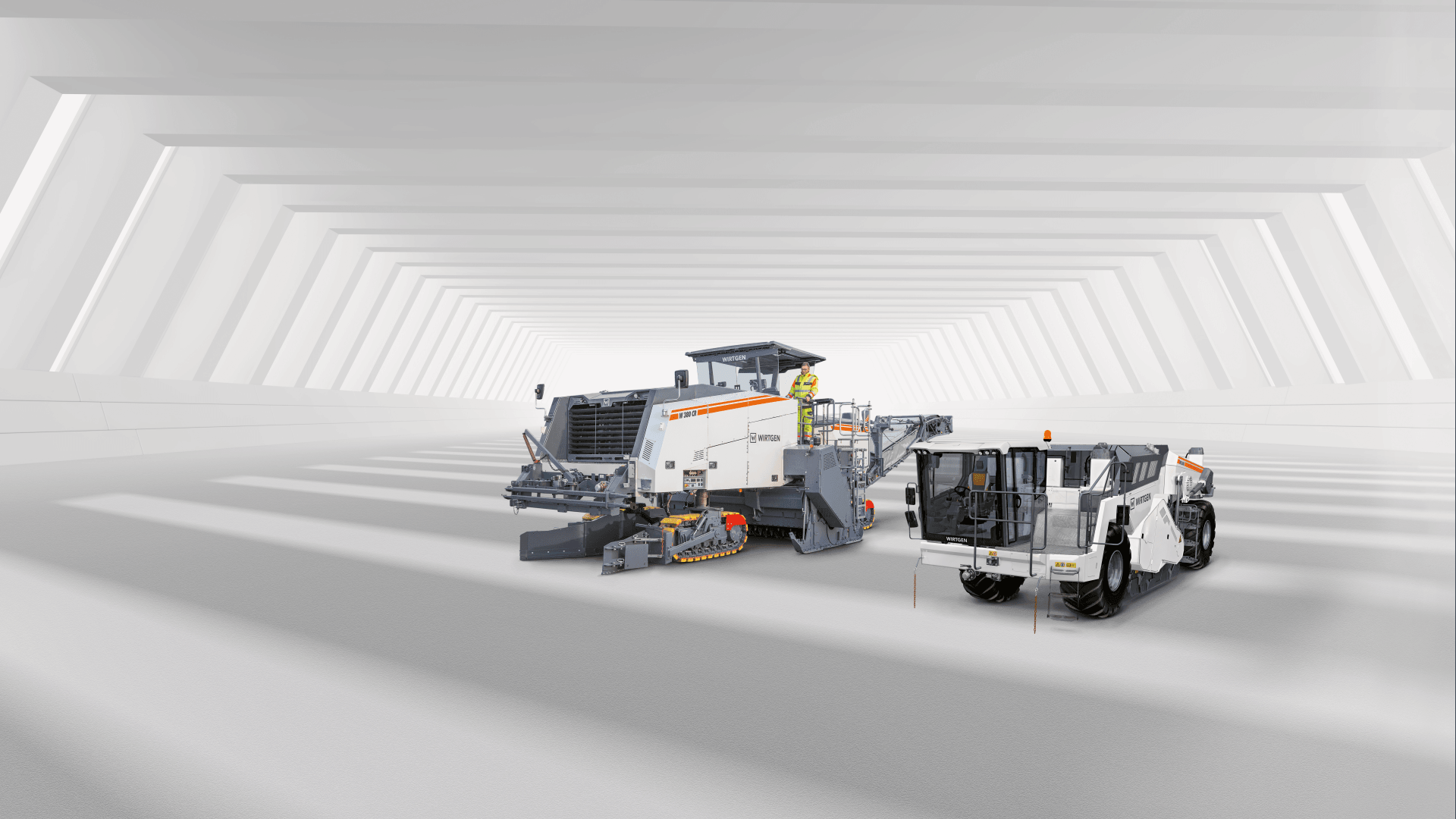

Recyclers and soil stabilisers

Cold recyclers are used to prepare asphalt pavement on site. In this process, the existing pavement is granulated with the milling and mixing rotor and prepared by adding precise amounts of bituminous binding agents, cement and water. The result is a homogeneous material that can be used to directly repave the soil. Soil stabilisers use the milling and mixing rotor to mix pre-spread binding agents such as lime or cement into the existing, less stable soil and transform it into a high-quality material directly on site.

The WR series cold recyclers and stabilisers have a variable mixing chamber and microprocessor-controlled injection systems for the addition of bitumen emulsion, water or foamed bitumen. Thanks to an efficient hydraulic flow divider, their all-wheel drive provides maximum traction, while the four-fold full-floating axles ensures best possible ground clearance in difficult terrain. The WR series machines are therefore ideal for a variety of application scenarios ranging from cold recycling - structural road rehabilitation - to the stabilization of various construction materials such as, for example, in soil stabilisation or consolidation in the construction of traffic infrastructure.

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.