MT 3000-3i Offset PowerFeeder

t/h

kg

m

State-of-the-art high-performance feed technology with outstanding operating convenience and a wide range of applications

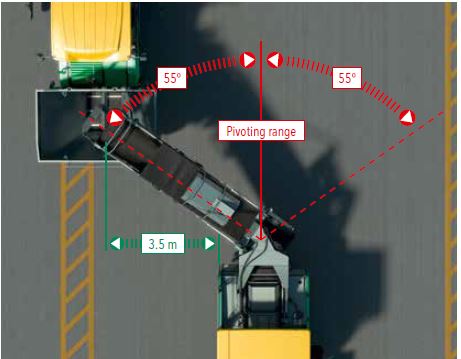

The new MT 3000-3i Offset PowerFeeder combines state-of-the-art, high-performance feed technology with outstanding operating convenience. The optimized conveying concept ensures reliable uninterrupted and jolt-free transfer of mix to the paver. The pivoting and height-adjustable conveyor of the MT 3000-3i Offset creates a wide variety of applications, ensuring a high level of usage. The ErgoPlus 3 operating concept is another step forward in making operation much easier. It also incorporates a new service and maintenance concept with optimized access to all cleaning and maintenance points.

Show lessTechnical specifications

- Exhaust emissions after-treatment

- Exhaust emissions standard

- Version

- Manufacturer

- Fuel tank

- Nominal output

- ECO mode output

- Guaranteed sound power level LWA

- Sound pressure level LPA at the operator’s stations (≤)

- Type

-

- Exhaust emissions after-treatment

- DOC, DPF, SCR

- Exhaust emissions standard

- European exhaust emissions standard V, US standard EPA Tier 4f

- Version

- liquid-cooled 6-cylinder diesel engine

- Manufacturer

- Deutz

- Fuel tank

- 450 l

- Nominal output

- 160 kW / 2,000 U/min

- ECO mode output

- 150 kW / 1,800 U/min

- Guaranteed sound power level LWA

- 108 db(A)

- Sound pressure level LPA at the operator’s stations (≤)

- 80 db(A)

- Type

- TCD 6.1

- Speeds

- Operating speed (up to)

- Travel speed (up to)

- Version

- Ground contact

- Traction drive crawler tracks

- Lubrication of track rollers

- Track tension adjuster

-

- Operating speed (up to)

- 25 m/min

- Travel speed (up to)

- 4,5 km/h

- Version

- provided with rubber pads

- Ground contact

- 3,060 mm x 305 mm

- Traction drive crawler tracks

- separate hydraulic drives with electronic control

- Lubrication of track rollers

- lifetime

- Track tension adjuster

- spring assembly

- Push-rollers

- Version

- Hopper capacity of material feeder

- Width of material feeder

- Feed height of material feeder

- Positions of material feeder

-

- Version

- oscillating

- Hopper capacity of material feeder

- 15 t

- Width of material feeder

- 3 680 mm

- Feed height of material feeder

- 600 mm

- Positions of material feeder

- can be adjusted in a forward direction by 75 mm or 150 mm

- Conveyors

- Conveyor drive

- Version

- Belt width

- Screed heating

- Pivoting angle

- Max. transfer height standard

- Max. transfer height option

- Augers

- Auger drive

- Auger speed

- Auger diameter

- Conveying system capacity (up to)

- Augers

- Pivoting conveyor

-

- Conveyor drive

- separate hydraulic drives

- Version

- 2 continuous rubber conveyor belts

- Belt width

- 1 100 mm

- Screed heating

- infrared heating panel, diesel-operated

- Pivoting angle

- 55 °

- Max. transfer height standard

- 3 600 mm

- Max. transfer height option

- 3 900 mm

- Auger drive

- separate hydraulic drives

- Auger speed

- 100 U/min

- Auger diameter

- 300 mm

- Conveying system capacity (up to)

- 1 200 t/h

- Augers

- 2, in material hopper

- Pivoting conveyor

- hydraulically pivoting

- Capacity

- Capacity, 2.5 m machine

- Capacity, 3 m machine

- Passive homogenization promoted by use of additional hopper

-

- Capacity, 2.5 m machine

- 20 t

- Capacity, 3 m machine

- 25 t

- Passive homogenization promoted by use of additional hopper

- 18 t

- Weight

- Length in transport position

- With pivoting conveyor

- With pivoting conveyor and funnel

- Track gauge

- Transport width

-

- Weight

- 24 285 kg

- With pivoting conveyor

- 14,49 m

- With pivoting conveyor and funnel

- 15,02 m

- Track gauge

- 2,36 m

- Transport width

- 3 m

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.