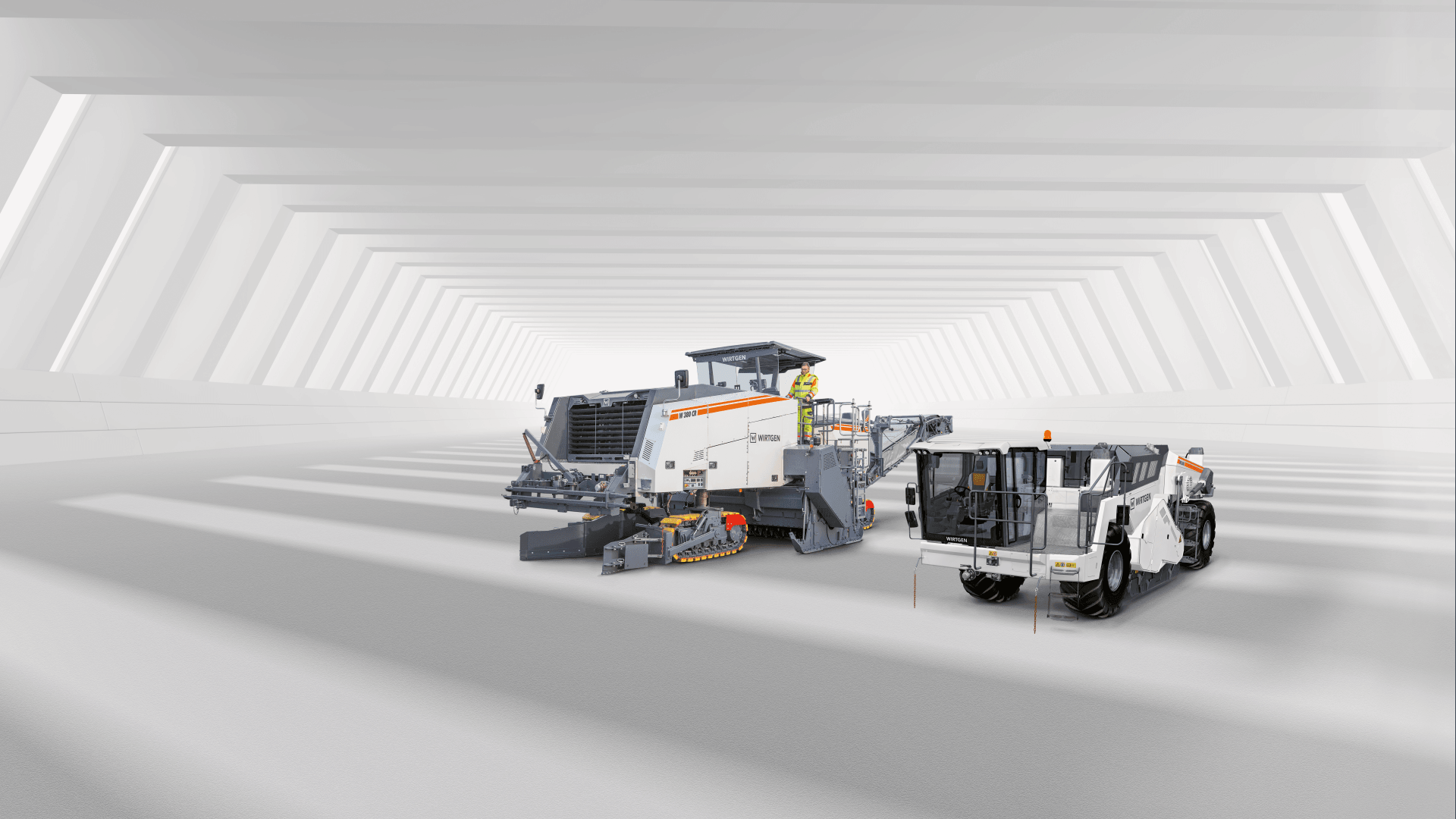

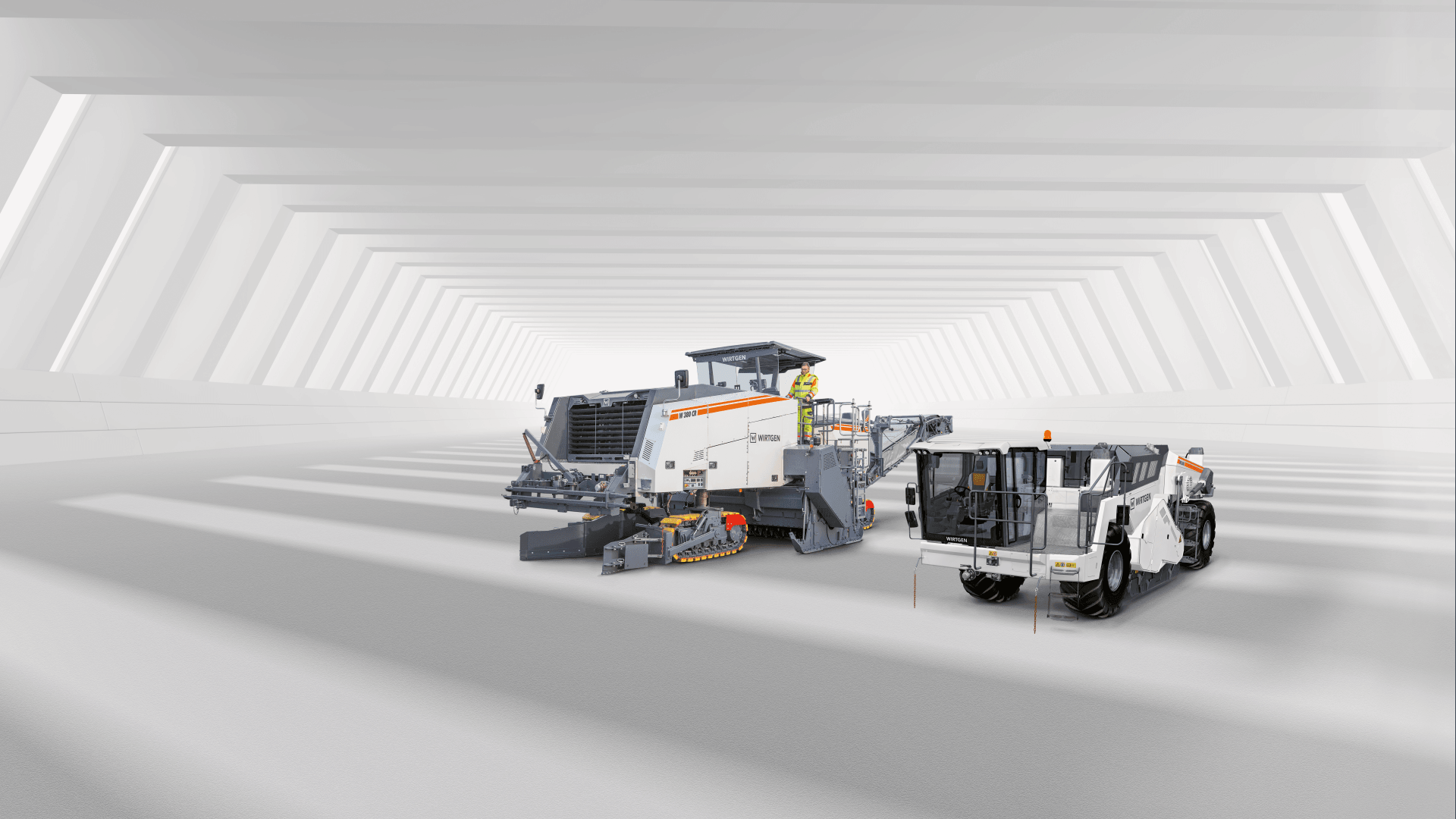

Recyclers and soil stabilisers

Cold recyclers are used to prepare asphalt pavement on site. In this process, the existing pavement is granulated with the milling and mixing rotor and prepared by adding precise amounts of bituminous binding agents, cement and water. The result is a homogeneous material that can be used to directly repave the soil. Soil stabilisers use the milling and mixing rotor to mix pre-spread binding agents such as lime or cement into the existing, less stable soil and transform it into a high-quality material directly on site.

The tractor-towed stabiliser can be attached to a tractor in a few swift moves. The adjustable rotor plate ensures the homogeneous mixing quality of binding agent and soil. Side plates which move on skids, the mechanical belt drive on each side and the effective milling and mixing rotor contribute to the high performance. In the soil improvement process, the tractor-towed stabiliser produces soils suitable for placing and compacting, while in the soil stabilisation process, it creates load-bearing surfaces.

Tractor-towed stabilisers

| Working width max. | 2 500 mm |

| Working depth | 500 mm |

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.