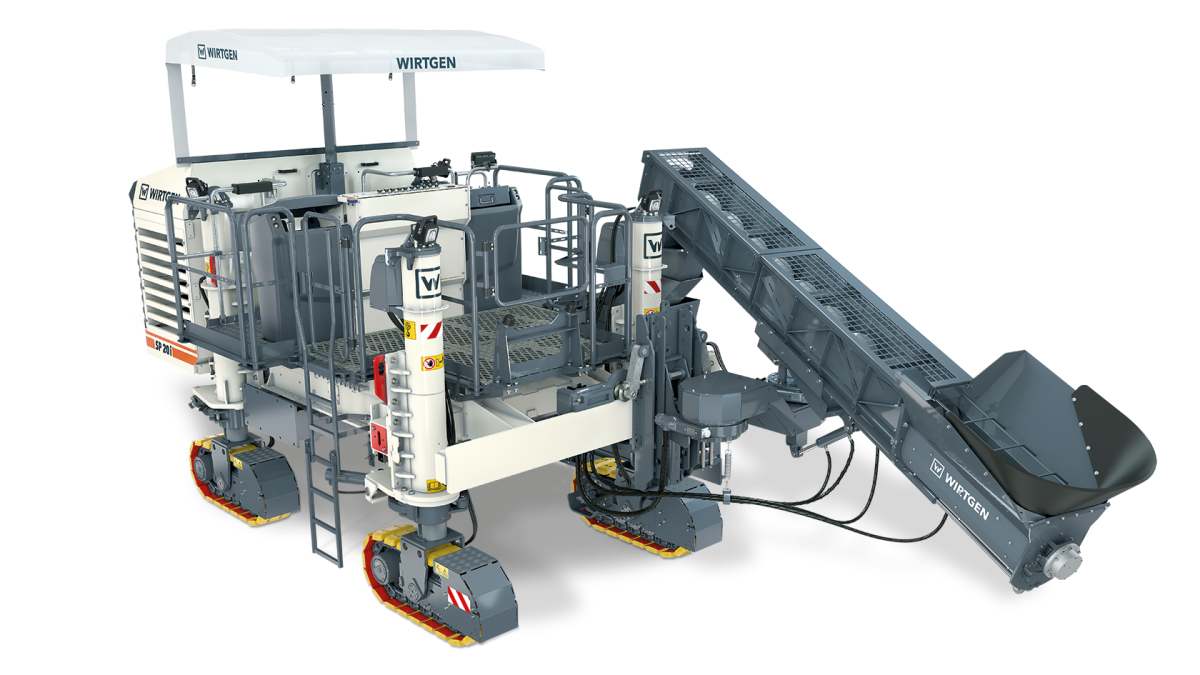

SP 20

EU Stage 3a/US EPA Tier 3

2 500

mm

2 000

mm

Cost-efficient and professional offset concrete paving

Technical specifications

- Exhaust emissions category

- Number of track units

- Operating weight, CE

- Displacement

- Hydraulic height adjustment

- Max. working speed

- Max. travel speed

- Max. mould width

- Max. mould height

- Height adjustment, mechanical

- Rated power

- Lateral adjustment of mould

-

- Exhaust emissions category

- EU Stage 3a/US EPA Tier 3

- Number of track units

- 4

- Operating weight, CE

- 13 900 kg

- Displacement

- 6 l

- Hydraulic height adjustment

- 1 000 mm

- Max. working speed

- 0 - 15 m/min

- Max. travel speed

- 0 - 35 m/min

- Max. mould width

- 2 500 mm

- Max. mould height

- 2 000 mm

- Height adjustment, mechanical

- 560 mm

- Rated power

- 118 kW / 160 HP 2,100 rpm

- Lateral adjustment of mould

- 1 100 mm

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.