Large-scale processing of non-cohesive soils

Soil stabilization is proving to be the optimum solution whenever the properties of soil have to be altered to make it suitable for further roadworks.

Soil stabilization is the method of choice when it comes to ensuring the load-bearing capacity and quality of soil in preparation for road construction projects. The targeted addition of stabilizing agents can, for instance, help to reduce the moisture content of soil, which is vital for further roadworks. Compared to the process of exchanging the entire soil, soil stabilization is an economical and resource-saving method. Cost savings result from the simpler job-site logistics, for instance, with fewer lorry trips and shorter construction periods. Resources are also conserved, because all of the existing soil is used in the stabilization process with only stabilizing agents such as lime or cement being added – or a combination of them.

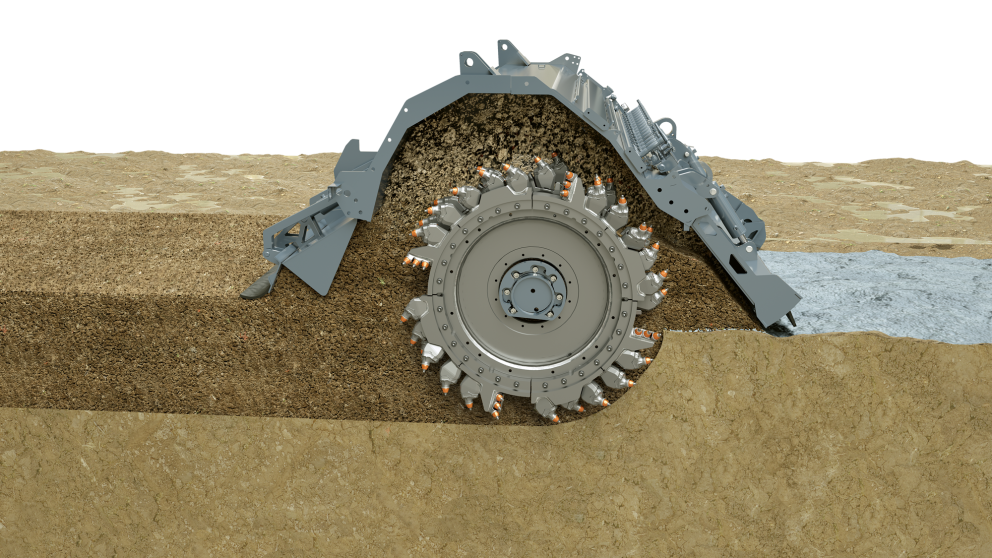

Many invitations to tender continue to specify that the soil is to be exchanged – but this is no longer a state-of-the-art method. The soil stabilizer uses its powerful milling and mixing rotor to mix pre-spread stabilizing agents such as lime or cement into existing soil with insufficient bearing capacity, transforming it into a high-grade building material right on the spot. The homogeneous mixture of soil and stabilizing agent that is produced offers a high load-bearing capacity as well as lasting resistance to water and frost, and volume stability. Typical applications include the construction of paths, roads, motorways, routes, parks and sports grounds, industrial estates, industrial plants, airfields, dams, backfilling and landfills.

“Soil stabilizers and tractor-towed stabilizers from WIRTGEN are ideally suited for mixing soil with binding agents prior to compaction.”

WIRTGEN Soil stabilizersIn soil stabilisation, a distinction is made between improving the soil and stabilising it. Lime improves the paving properties and compactability of wet, cohesive soil. This is known as soil improvement. If the aim is to stabilise the soil cement is used because it lastingly enhances the load-bearing capacity, volume stability and resistance to water and frost. Soil can be stabilised or homogenised even without the use of stabilising agents.

A machine train is generally required if the properties of the soil are to be lastingly improved. This begins with a binding agent spreader that deposits the stabilizing agent evenly, followed by a Wirtgen soil stabilizer. The WR 250 uses its milling and mixing rotor to mix the soil homogeneously with the pre-spread lime. A pressurized scraper on the rear milling drum flap ensures that the treated material is smoothed evenly. While a grader profiles the soil mixture, rollers for soil compaction ensure optimum compaction.

Stabilisation with cement creates water-bound base courses. The binding agent is laid by a towed spreader, which is followed by a water tanker. Behind it, the milling and mixing rotor of the Wirtgen soil stabiliser mixes the soil with the pre-spread cement to form a homogeneous mass. At the same time, water is sprayed into the mixing chamber by means of an injection bar. Here, too, graders profile the treated material and rollers complete the job by ensuring optimum compaction.

Perfect stabilisation: the powerful milling and mixing rotor of the WR 250 DURAFORCE blends the pre-spread into a homogenous soil and stabilising agent mix.

Product presentation

Recyclers and soil stabilisers

Compactors

Motor Graders