2 in 1: Rock crushing and compaction with HAMM's VC compactors

For bauma 2016 in Munich, HAMM is bringing along its VC compactors, which are now ready for series production. These compactors with a vibration crusher drum carry out 2 tasks simultaneously and to the highest quality standards: They crush rock and compact it at the same time. Three years ago, the series prototype attracted a great deal of attention at bauma. In the meantime, HAMM has subjected the vibration crusher drums to intensive testing in different applications in the course of many tough assignments, refined the machine concept and developed the VC machines to become genuine heavy-duty units.

The initials VC in the compactor's name stand for "vibration crusher" on account of the fact that these compactors are intended for a very special kind of multitasking. During compaction, they crush the most diverse construction materials and minerals by means of vibration. This enables them to bring along two major benefits to the construction site – they save time and money.

Rock crusher and padfoot roller in one

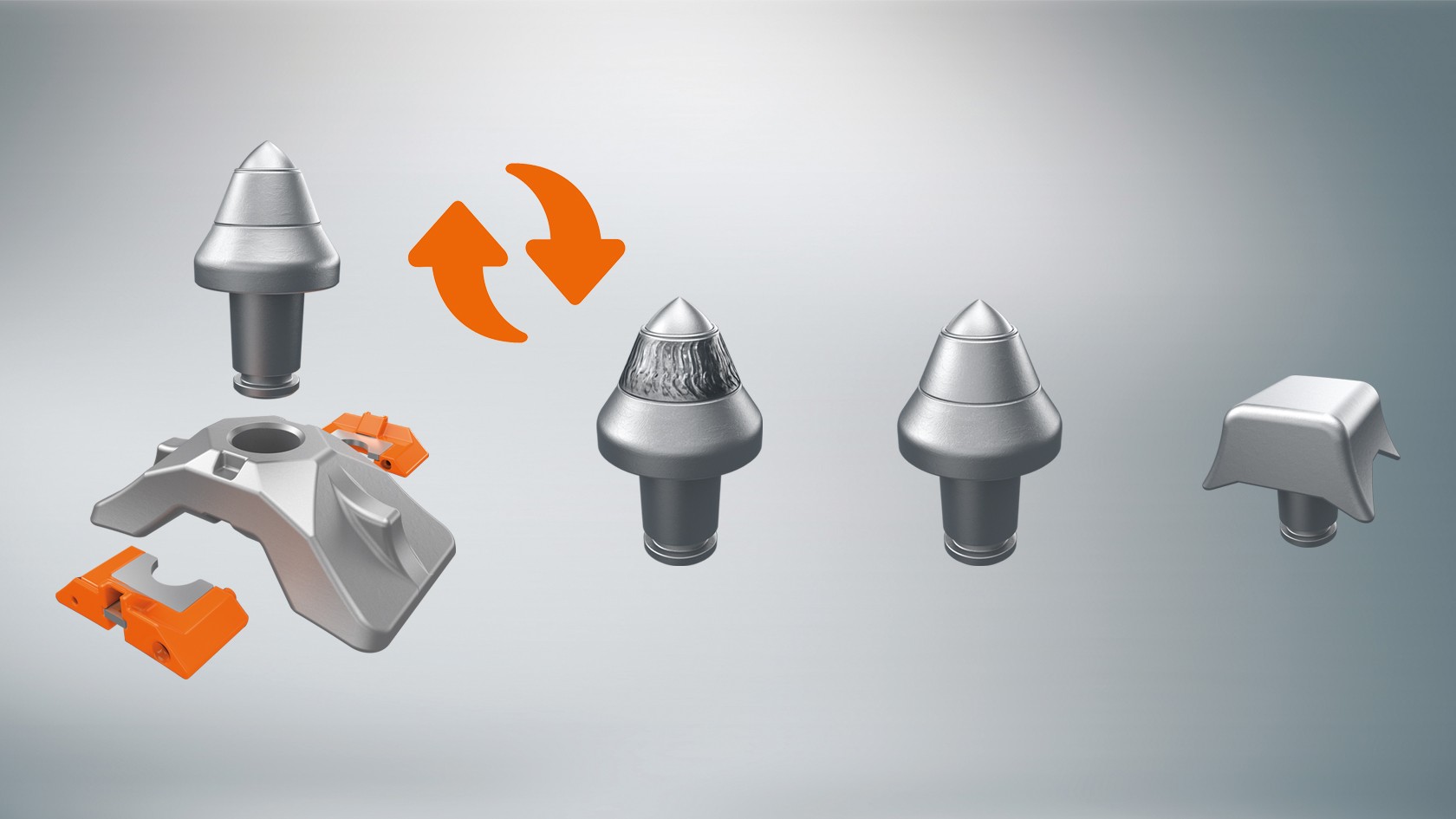

The VC compactors have been designed for crushing and loosening rock and stone. To this end, the drum is equipped with a special quick-change toolholder system. This enables the use of special padfoot inserts as well as chisels. Accordingly, the area of application ranges from road building and earthworks to the preparation of approaches in tunnel building and rock engineering.

The quick-change toolholder system brings flexibility

A few simple steps is all it takes to fit a wide range of tools in the drum's 150 quick-change toolholders. The design of the quick-change toolholders is just what you would expect from HAMM – well thought out and ergonomically outstanding. When working on the design, for example, care was taken to ensure that the chisels are resistant to soiling in the holders, making them easy to swap. Incidentally: The tools are not destroyed during the changing process but can be repeatedly used until they are worn out.

Two types of chisel available

The HAMM programme currently includes two different chisels for crushing or loosening: A classic chisel and a special mining chisel for heavy-duty jobs. Their geometries together with the integral solid carbide tips are specially designed for materials with different compressive strengths.

A huge range of potential applications

The range of available tools results in an exceptionally wide application spectrum for the VC compactors with crusher drum. Fitted with chisels, the crusher drum breaks up rock layers consisting of basalt, granite or minerals of comparable compressive strength as well as mixed soils, while compacting the soil to a great depth. Road building applications include homogenisation of rock as well as compaction during cold recycling. The VC compactors are equally effective in crushing concrete rubble for recycling. Potential applications include working in rocky terrain: Many applications are possible, from preliminary rock breaking or loosening to the preparation and maintenance of access ways in quarries, right up to track laying in tunnels or mines. Equipped with padfoot inserts, the machine can compact cohesive soils. This application increases the efficiency over that of a conventional padfoot roller, because when compacting very abrasive, fine-grain minerals, the padfoot inserts can simply be replaced as wearing parts, rather than replacing the complete drum.

Optimise processes – save resources

The use of VC compactors results in a reduction in transport movements and simplified handling on the construction site. This is not only extremely environment-friendly, but also helps optimise processes. For example, when crushing hard rock with simultaneous compaction, far fewer excavators and crushers are generally required. This streamlines the process, reduces the fuel requirement and saves a great deal of time and expenditure. Another example is pre-crushing of rock prior to its removal by cold milling. Experience gained in tunnel building and surface mining shows that milling capacity can be greatly increased through pretreatment with the crusher drum.

Available for Tier 3 and Tier 4 markets

To enable as many customers as possible to take advantage of this innovative and versatile technology, HAMM is offering the vibration crusher drum for 2 compactors: The H 25i VC with a 160 kW engine (complying with Tier 4i/Stage IIIB) and the 3625 HT VC with a 155 kW engine (complying with Tier 3/Stage IIIA). The VC compactors with crusher drum are fuel-efficient thanks not least to the engines employed.

Hammtronic for exceptional gradeability

The Hammtronic machine control system fitted as standard ensures low operating costs. It optimises the engine output, adjusts the operational states of the travel and vibration drives to the ambient conditions and enables tremendous gradeability of more than 60%, while being able to compact and crush at the same time.

Heavy-duty equipment included

In order to get the compactors ready for the extremely tough requirements, the VC machines run on earth-moving tyres as standard. This ensures dependable progress, even in difficult terrain. In addition, HAMM always equips both models with a ROPS cab, reinforced articulated joint and reinforced undertray. Both compactors also use the same front frame with a 2200 mm wide drum which differs from the standard machine in that it features a strengthened mounting bracket, a drive with more than 30% extra torque and a fixed unbalanced mass. This means that the compactors are perfectly prepared, in every respect, for the tough job ahead.