Unbeatable versatile: Wirtgen 3800 CR – Cold recycler and high-performance cold milling machine

By supplying the 3800 CR as a rear loader, Wirtgen not only offers an efficient and flexible solution for in-situ cold recycling: the 3800 CR also excels as a high-performance cold milling machine.

The Wirtgen cold recycler‘s versatile applications are just what the US road construction contractor Dunn prizes, for they enable the company to use the machine for a wide range of tasks, fully utilizing its capacity. ”The work is really challenging, with varying site conditions, complex designs, and tough materials. Since every project is different, it’s important for us to have versatile, reliable equipment that is up to the task”, explains Mark Stahl, Vice President Operations, Dunn Company.

On CH 11 the Wirtgen 3800 CR proved its versatility by milling off 4 cm of the top layer before starting the recycling process.

Dunn also opted to use the 3800 CR and the environmentally- friendly cold recycling technology for the recycling construction project near the Interstate 57 in Champaign County, Illinois. The recycler reliably rehabilitated two county highways, CH 11 and CH 20, working alongside a Vögele VISION 5200-2 road paver and two Hamm rollers, a HD+ 140 VV and a HD+ 110 VV. “As a pioneer in the recycling industry, Wirtgen brings their experience to offer great customer support. They’re a great partner”, comments Mark Stahl, explaining the company’s decision to use Wirtgen machines.

Down-cut process boosts quality

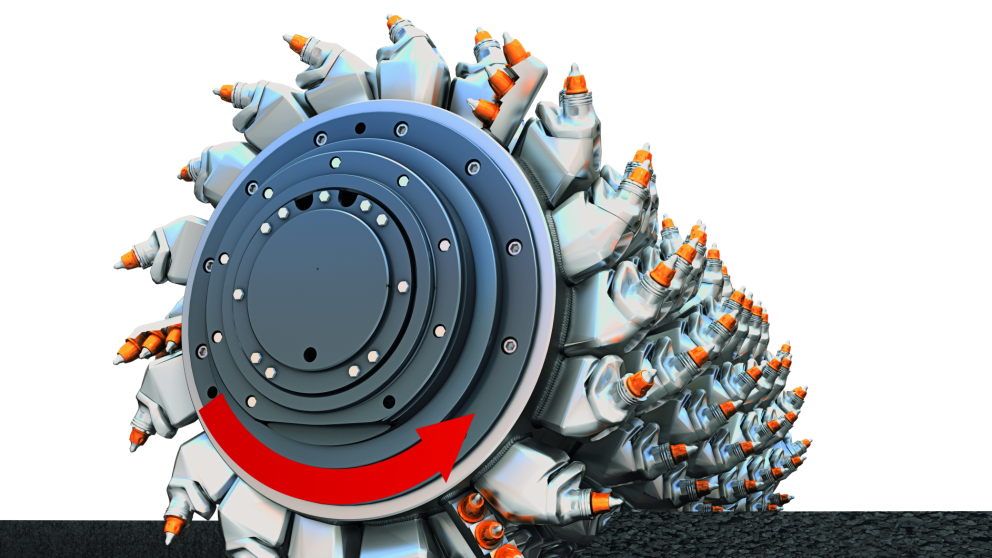

The customer also elected to use the down-cut process, a method that was specially developed for in-situ cold recycling by Wirtgen‘s experienced application experts. With this concept, the milling drum not only rotates against the direction of travel as in the up-cut process, but also in the direction of travel. With the so-called „rear load“ method the recycled milled material is rear loaded directly onto a road paver which immediately paves and pre-compacts the material. The final compaction is then carried out by rollers. With the down-cut process, precise control of the particle size of the milled material is possible during material processing – especially when milling very brittle, thin asphalt roads. It also makes material feeding easier.

The down-cut process: The milling and mixing rotor rotates in the direction of travel. This results in an optimized small particle size, avoiding large blocks.

The up-cut process: The milling and mixing rotor rotates against the direction of travel.

Advantage: Flexibility

This is also true in Champaign County. On CH 20, recycling could start right away. On CH 11, however, 4 cm of the surface course had to be removed at first. No problem for the cold recycler: this is where it can prove its versatility - in being used as high performance cold milling machine, as well. In the recycling process, the robust milling and mixing rotor of the 3800 CR mills and granulates the damaged asphalt layer in one pass to a depth of 10 cm. At the same time, the cement, which is pre-spread by a Streumaster binding agent spreader, is mixed in.

Water and bitumen emulsion or foamed bitumen are injected into the mixing chamber via injection bars from a water and binding agent tanker travelling in front of the machine. The material is immediately homogenously mixed so that a new mix is produced in situ. The ejectors positioned on the rotor then transfer the mix to the primary conveyor of the 3800 CR. The slewable and height adjustable discharge conveyor rear loads the mix to the material hopper of the VISION 5200-2 asphalt paver that then paves a 10 cm layer, true to line and level, and also pre-compacts it at the same time. The two Hamm asphalt rollers HD1 140 V and HD+ 110 VV then provide the final touch by subsequently compacting the pavement.

Dunn mills and creates cold-recycled RAP mix in Wirtgen 3800 CR and places into Vögele paver VISION 5200-2 using a "rear-mounted conveyor".

Mark Stahl is also satisfied with the results: “Cold in-place recycling (CIR) is a good complement to traditional construction methods. By re-using materials in-place for the intermediate layer, we help the wearing courses perform better while reducing the time, cost and environmental impact of projects. That benefits agencies as well as the taxpaying public”.

The job was successfully completed in time. This was naturally not only great news for Dunn‘s client. The road construction company also profited from the prompt completion of the project, as the next job is already lined up for the 3800 CR – this time not in cold recycling, but in milling.

Equipped with a fine milling drum, the 3800 CR can roughen surfaces and increase grip and evenness.

Two in One: High-performance milling with 3800 CR

Equipped with a loading conveyor, the 3800 CR can also be used as a high-performance cold milling machine using the standard up-cut process. The powerful engine and high conveying capacity make the 3800 CR the ideal choice for milling jobs involving extremely high outputs such as the removal of asphalt pavements at full depth. High advance rates and milling depths of up to 35 cm ensure the quick completion of large construction projects such as the replacement of surface courses on highways or airport runways. “Before recycling, we can pre-mill with the recycler to allow room for surface courses, as well as correct elevation and slope issues,” Stahl said.

Dunn's experienced team quickly converts the 3800 CR from a milling machine into a recycler.

This ensures that the previous level is maintained once a new surface course is laid on top of the recycled layer. The highly versatile 3800 CR is a true all-rounder for road rehabilitation – something that is widely appreciated, not just by the Dunn Company from Illinois.