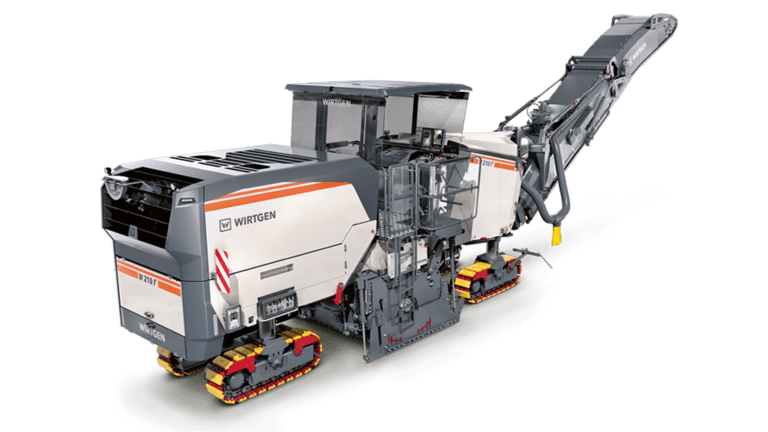

W 210 Fi Large Milling Machines

US EPA Tier 4f

2,200

mm

330

mm

Innovative professional machine offering maximum milling performance

Show less Highlights

Technical specifications

- Exhaust emissions category

- Operating weight, CE

- Milling width

- Milling depth max.

- Displacement

- Net weight of the machine without operating agents

- Max. travel and milling speed

- Maximum power

- Rated power

- Shipping weight, US standard (full fuel tanks, without water)

-

- Exhaust emissions category

- US EPA Tier 4f

- Operating weight, CE

- 29,300 kg

- Milling width

- 2,200 mm

- Milling depth max.

- 330 mm

- Displacement

- 18.1 l

- Net weight of the machine without operating agents

- 30,500 kg

- Max. travel and milling speed

- 0 - 100 m/min (0 - 6 km/h )

- Maximum power

- 563 kW / 766 HP

- Rated power

- 563 kW / 766 HP 1,950 min-1

- Shipping weight, US standard (full fuel tanks, without water)

- 31,700 kg

Downloads

All details, illustrations and texts are non-binding and may include special equipment. We reserve the right to make technical changes without prior notice. Performance data are dependent upon actual operational conditions.