The new SB 300 and SB 350 Fixed-Width Screeds

8

Apr

'19

Potentially record-breaking pave widths and practical features

With VÖGELE’s new fixed-width screeds, surface courses as much as 16 to 18m wide can be paved without joints. The screeds also offer users new functions such as hydraulic tamper-stroke adjustment, extra-wide hydraulic bolt-on extensions, user-friendly installation aids and an efficient heating system.

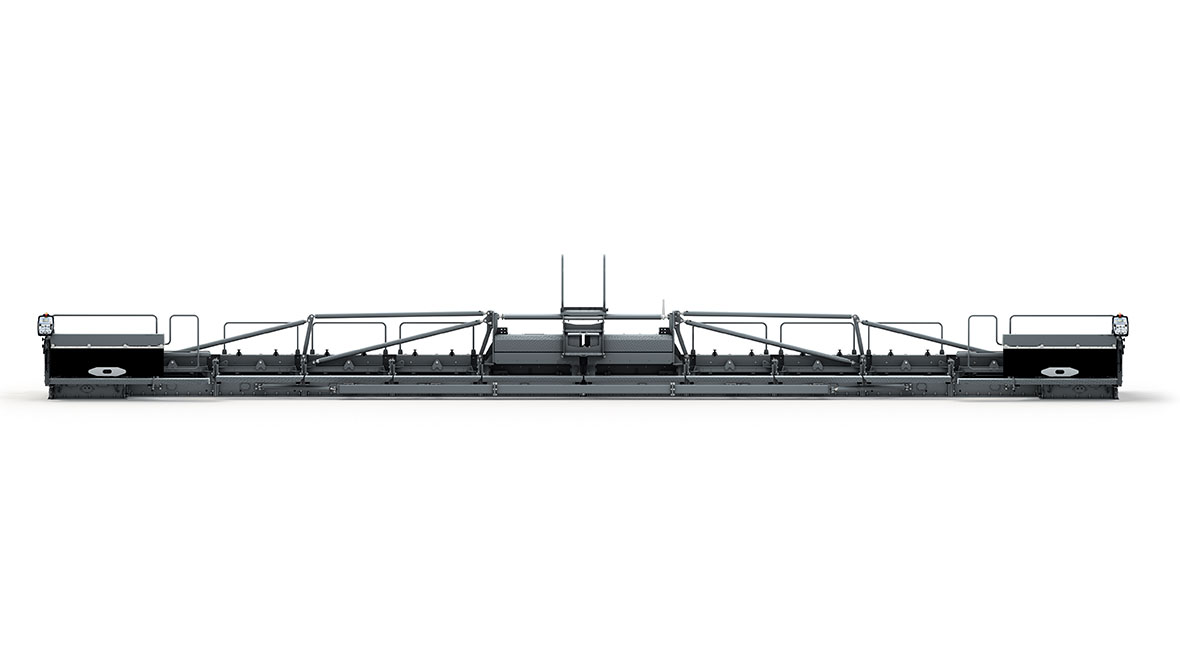

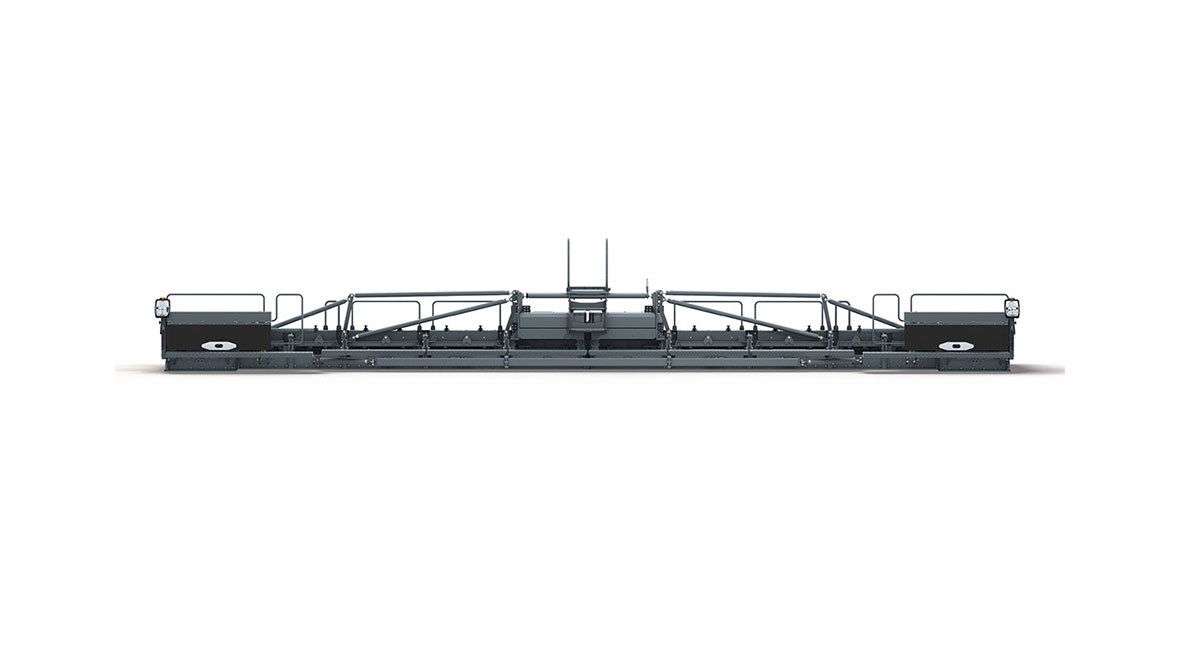

Along with numerous paver models, JOSEPH VÖGELE AG have also developed two new screeds right on time for Bauma 2019 – raising the bar once again: with basic widths of 3 and 3.5m and maximum pave widths of 16 and 18m, the SB 300 and SB 350 Fixed-Width Screeds are the highest-performing screeds in the world market leader's range. They guarantee maximum surface accuracy, even across large widths – paving without longitudinal joints. When combined with VÖGELE’s new flagship, the SUPER 3000-3(i) large paver, the screeds can even pave base courses up to 50cm thick. The SB 300 can also be combined with other Premium Line pavers such as the SUPER 1800-3(i), SUPER 1900-3(i) and SUPER 2100-3(i).

Both screeds are available in the TV version (with tamper and vibrators) as well as in the high-compaction versions TP1 (with tamper and one pressure bar) and TP2 (with tamper and two pressure bars). The SB 300 and SB 350 are both additionally equipped with a new heating system that has two coils per heating rod: it heats the screed plate, tamper and pressure bars twice as fast and much more uniformly – getting them ready for use in a short time. “The new fixed-width screeds are not only designed for maximum pave width and performance, but also for maximum flexibility and efficiency,” says Björn Westphal, Product Manager at VÖGELE. “Apart from the latest screed technology, the SB 300 and 350 also incorporate user-friendly functions that, among other things, reduce set-up times and considerably accelerate the paving process, even when working with varying pave widths and layer thicknesses.”

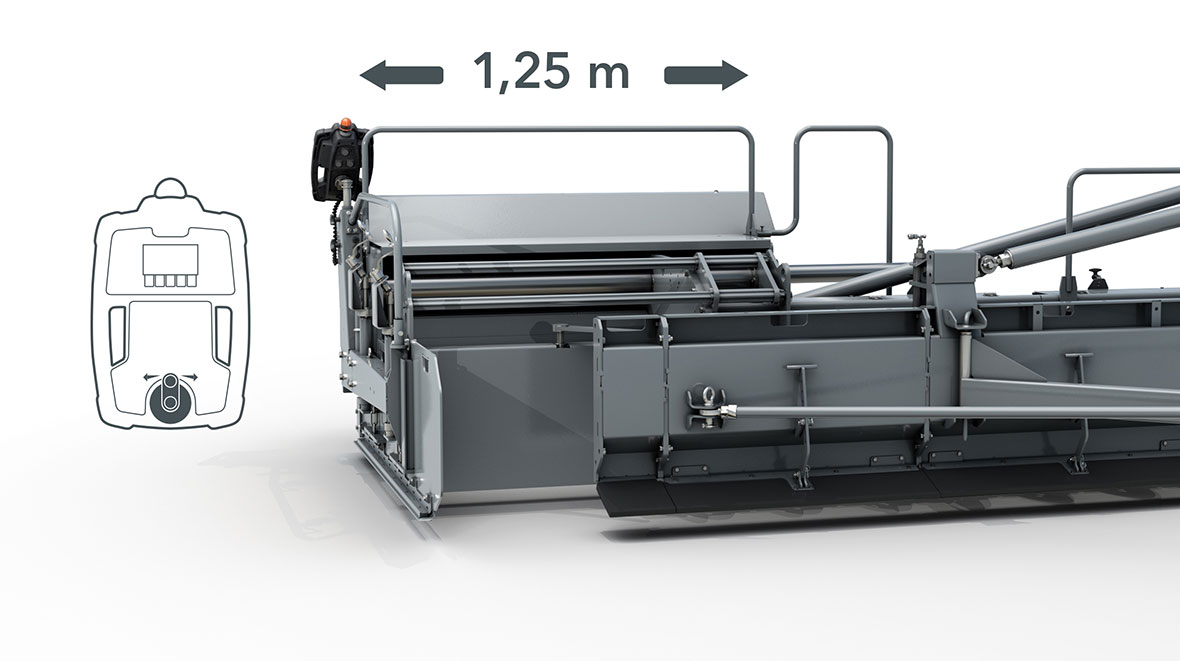

High flexibility thanks to hydraulic bolt-on extensions

The possibility of hydraulically adjusting both screeds by up to 2.5m with the newly developed extra-wide hydraulic bolt-on extensions is a globally unique feature: no longer confined to the previous range of 75cm, operators can now vary the pave width on both sides of the screed by as much as 1.25m using the SmartWheel. This offers a high degree of flexibility and saves time, too – especially on projects involving varying pave widths, since operators no longer need to manually mount or dismount fixed bolt-on extensions for differences of up to 2.5m. “If, for example, bridges need to be crossed in a construction project, the operators can adjust the screed to the new pave width without any mechanical conversion work, using the SmartWheel on the ErgoPlus 3 screed console,” explains Westphal. “This makes the SB 300 and SB 350 Fixed-Width Screeds extremely variable.”

Efficient and convenient: Practical functions and installation aids

VÖGELE have also greatly simplified the installation of fixed bolt-on extensions: a newly developed telescoping and positioning system helps operators to mount the individual bolt-on extensions correctly. As a result, they can be adjusted very easily, considerably reducing set-up times. Another advantage of the new screeds is the hydraulic tamper-stroke adjustment: until now, operators have had to manually set the tamper stroke to 2, 4, or 7mm whenever the layer thickness varied. The SB 300 and SB 350 Fixed-Width Screeds now offer the option of hydraulically adjusting the tamper stroke to 4 or 8mm via the ErgoPlus 3 operating system in a quick and convenient process. One push of a button is all it takes. “When paving in varying layer thicknesses with the same screed, this speeds up processes while guaranteeing high-quality compaction results,” Westphal continues, “The new fixed-width screeds are easy to mount and operate, despite their size.”