Roads and buildings built to stand the test of time require a foundation with a high bearing capacity. And this applies to every layer below the road surface or structure, from the subgrade to frost protection and base layers. Through soil stabilization and high-grade compaction, these layers gain the necessary load-bearing capacity and can act as the foundation for long-lasting roads and buildings. In short: building for the long term begins with the soil.

Strengthening the Foundation

“HAMM offers an extensive range of

products for all areas of earthworks

and stands for sophisticated machine

and compaction technology.”

Soil stabilization as a systematic and simple method of preparing the soil

The first step is developing a formula in advance on the basis of soil analyses. This specifies which binding agent (lime, cement, or a mixture of binding agents) is required in which proportions to achieve the desired properties.

Lime, cement, or mixed binding agents are distributed over the surface by binding agent spreaders. Soil stabilizers thoroughly mix the binding agents with the soil – sometimes with and sometimes without the addition of water, depending on the requirements. The result is a soil mixture with high compressive and shear strength; long-lasting water and frost resistance; and long-term volume stability. This mixing process is carried out in layers up to a maximum thickness of 50 cm. This is how dams that can withstand enormous loads over the span of many years – some of which are several meters high – and stable substructures are built all over the world each and every day.

“Soil stabilizers and tractor-towed

stabilizers from WIRTGEN are ideally

suited for mixing soil with binding agents

prior to compaction.”

Necessary load-bearing capacity

Compaction is what gives the soil the necessary loadbearing capacity, because the compactors, through their considerable weight combined with dynamic compaction, ensure that the grains are shifted in the soil to form a dense and thus load-bearing granular structure. Typically, compactors and – depending on the requirements – pneumatic tire rollers carry out this soil preparation work. They work hand in hand with graders to ultimately create a level subgrade – the ideal foundation for long-lasting roads and buildings.

The subgrade is also frequently covered with a frost protection layer. Impact crushers are an ideal tool for producing the graded aggregates needed for this purpose. Special pavers are available to lay the aggregate, and compaction is carried out by compactors or tandem rollers.

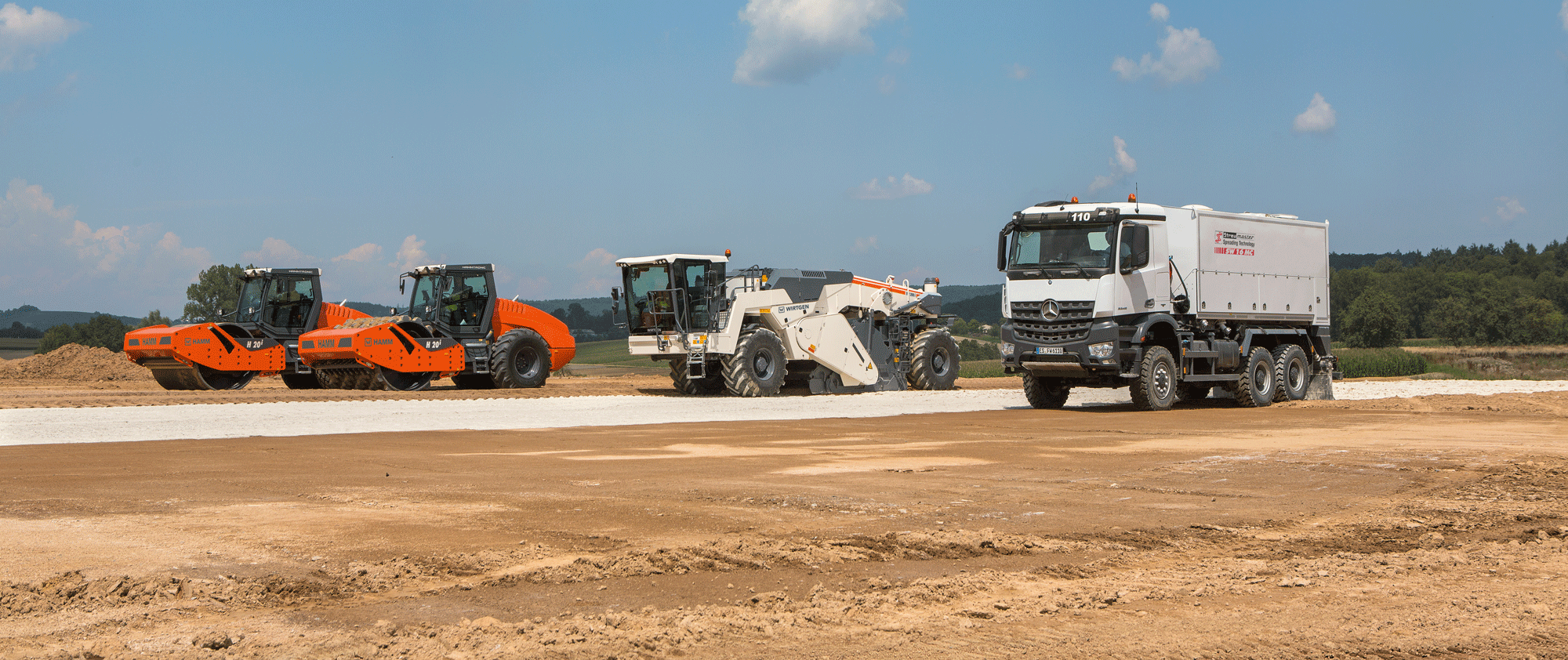

Running like clockwork … the Streumaster SW 16 MC spreads the quicklime, the WIRTGEN WR 200i works the binding agent homogeneously into the soil and immediately behind them the two HAMM H 20i rollers compact the soil.

Running like clockwork … the Streumaster SW 16 MC spreads the quicklime, the WIRTGEN WR 200i works the binding agent homogeneously into the soil and immediately behind them the two HAMM H 20i rollers compact the soil.

: In some applications, e.g. soil stabilization with cement, HAMM compactors with smooth or padfoot drum (18 t and more) are also used.

: In some applications, e.g. soil stabilization with cement, HAMM compactors with smooth or padfoot drum (18 t and more) are also used.